The problem of conservation and economical use of energy carriers is currently very acute. Residents of the city usually do not have much opportunity to save money, since all apartments are connected to the central heating system.

Long burning wood stove in the country

The prices for housing and communal services for all apartments of equal area will be the same, so everyone ends up in the same conditions. Another thing is the private sector with an individual heating system. This is where you can be smart and get space for a creative approach to solving a problem. In this article, we will learn that long-burning wood-burning stoves are one of the best options for getting out of this situation.

Actually, the efficiency of our home heating will depend on two main factors:

- The quality of insulation (thermal insulation) of the walls and windows of the building;

- The efficiency with which our heating installation (stove or boiler) uses fuel.

The purpose of this article will be to introduce you to one of the types of economical and productive wood-burning stoves that allow you to ensure the most complete combustion of logs. These heating installations are called pyrolysis ovens. Every year their popularity is increasing more and more, so many people are thinking about how to build such a heater with their own hands. How long-burning pyrolysis furnaces work, their internal structure, as well as instructions for self-assembly - you will learn all this by reading our article.

Content

- The combustion process and the mechanism of pyrolysis

- Why are kilns called long-burning kilns?

- Advantages and disadvantages of pyrolysis ovens

- Choosing a long-burning stove for a summer residence

- Installation of a purchased gas-generating furnace

- Making a long-burning stove with your own hands

- Pyrolysis furnace from improvised means (barrel, cylinder, thick-walled pipe)

- Brick pyrolysis oven masonry

- Video. Do-it-yourself long-burning brick oven

The combustion process and the mechanism of pyrolysis

The main physical phenomenon, without which it is impossible to imagine the operation of any furnace, is the oxidation of various substances by oxygen contained in the air. Fire, tamed by our ancestors millions of years ago, has become so familiar today that we don’t even think about how combustion occurs, with which each of us has been familiar since childhood. A simple, at first glance, the question “how does firewood burn?”, In fact, requires a separate explanation. After all, without understanding the basics, we will not be able to figure out how economical pyrolysis ovens work and why they are so good and economical.

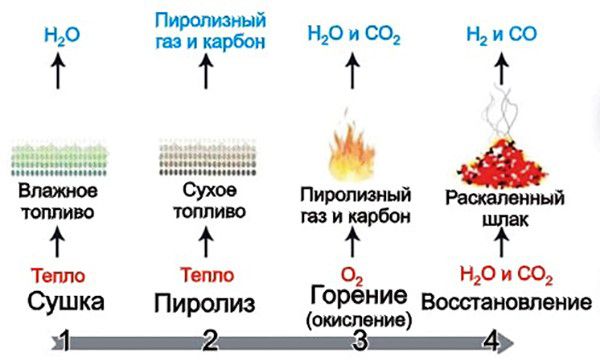

Actually, the formation of a flame occurs in several stages:

- First, the wood is heated and dried, releasing water vapor into the environment, which prevents the fire from starting. This requires an external source of energy, which is usually flammable paper, liquid for kindling, or a pile of small burning chips.

- Firewood, which from the point of view of chemistry are complex organic structures, consists of three main elements: carbon, hydrogen and oxygen. When heated, the wood decomposes, and these components, in the form of various simple gaseous compounds, begin to be released into the surrounding space. The common name for all substances formed during heating of the fuel is pyrolysis gases, and for the process itself - pyrolysis.

- In the next stage, the decomposition products of the wood ignite, and more and more accelerate the pyrolysis of the remaining logs, providing the fire with fresh fuel.

- In the end, the tree burns out, leaving behind some of the coals that did not have time to react with the oxidizing agent.

How combustion occurs

Actually, the idea that made it possible to build long-burning furnaces is to ensure the most complete decomposition of the fuel so that after its use there is practically no unburned waste left. To do this, it was necessary to slow down pyrolysis as much as possible so that the entire volume of firewood gradually and completely decomposed into pyrolysis gases.

Why are kilns called long-burning kilns?

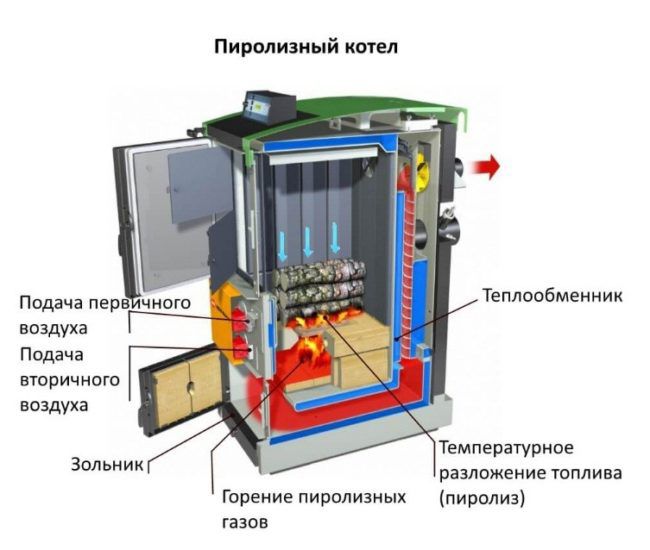

It is quite easy to distinguish a long-burning furnace from a conventional one. The fact is that the implementation of the idea of high-quality and complete pyrolysis required the introduction of not one, but two combustion chambers into the design of the stove. In the first, firewood slowly smolders, emitting a gas mixture of methane, hydrogen and other components.Smoldering is provided due to an artificially created lack of an oxidizing agent supplied to the furnace. Further, getting into the second chamber, the gaseous pyrolysis mixture already begins to fully burn, providing heating for the room in which the boiler is installed. Often, the secondary furnace is also additionally blown with air using a special fan. This ensures the most complete oxidation and combustion of the entire volume of gases, and leads to a significant increase in the efficiency of the entire heating installation.

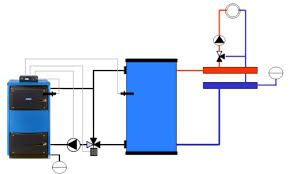

Pyrolysis ovens are very often also equipped with a separate cooling circuit, which evenly distributes heat to all rooms in the house. Such a heating boiler perfectly copes even with the most severe winter frosts, providing high-quality heating of the entire living space. An example of a block diagram that reveals the internal structure of a pyrolysis stove with a water block can be seen in the figure below.

Pyrolysis boiler device

Advantages and disadvantages of pyrolysis ovens

Nothing in this world is perfect, so even long-burning wood stoves are not without flaws. The main ones are the following:

- The price of modern high-tech long-burning pyrolysis furnaces with good performance in terms of efficiency will be quite high. However, you can significantly save money by constructing a heater with your own hands.

- Pyrolysis boilers of industrial production often require additional uninterrupted power supply to their auxiliary units: air injection systems (combustion chamber pressurization), water heating circuit pumps, sensors, etc.

- Long burning stoves are more finicky in terms of wood log moisture requirements.Insufficiently dried firewood placed in the firebox of a pyrolysis boiler can easily go out, stopping the operation of the entire heating system.

- Compared to gas (electric) boilers, boilers or columns, long-burning stoves are much larger and also require additional free space for storing firewood.

- You will have to manually throw up fuel for the pyrolysis boiler; this operation cannot be fully automated by 100%.

- A more complex water circuit device compared to other types of heating installations. The fact is that too supercooled coolant, returning from the batteries to the boiler heat exchanger, can interrupt the smoldering of firewood and extinguish the firebox. To avoid this situation, you have to install an additional pipe (the so-called "bypass"), which allows you to mix already heated water with cold water. Naturally, with the increasing complexity of the design of the heating circuit, the total cost of the entire device also increases.

At first glance, the list of shortcomings of long-burning wood-burning stoves seems quite impressive. And many people have a natural question: why is this type of stove so popular and in such good demand? The answer is simple and obvious: all the shortcomings of the pyrolysis plant are more than offset by the advantages that the owner of such a device receives:

- Fuel energy is used almost 100%. All loaded firewood will burn to the ground, completely transferring its heat to the heated room. High-quality, commercially manufactured, long-burning stoves have fantastic efficiencies, up to 90 percent.For greater clarity, we present a table below that compares the efficiency of various types of boilers.

Comparison of fuel efficiency indicators in boilers of different types

- Long burning wood stoves are convenient and easy to maintain, they produce almost no waste. Nothing remains of the firewood but a handful of ash.

- Environmental friendliness of the heating system. With full-fledged pyrolysis combustion, only water vapor and carbon dioxide are released into the atmosphere. During the operation of a high-quality pyrolysis oven, you will not feel any extraneous unpleasant odors, compared to a conventional oven. This is due to the fact that the source of such aromas are unburned complex organic compounds. In a long-burning furnace, fuel oxidation occurs by 100%, therefore it can be safely heated even with industrial waste.

- One "refueling" with logs is enough for 10-15 (and sometimes more) hours of continuous operation. No ordinary wood-burning stove can burn for such a long time.

- The heating system based on the pyrolysis boiler warms up the house very quickly and enters the operating mode.

- The power of a heater using the pyrolysis effect can be easily and smoothly adjusted, just like a gas or electric one. Unlike conventional solid fuel installations, in a long-burning furnace, the main heat is generated by the gas burned in a separate chamber. Accordingly, by controlling the level of oxygen supply to the furnace, we can easily change the heat release of the entire system.

Choosing a long-burning stove for a summer residence

Actually, having decided to acquire a long-burning stove, the question becomes before the future user: which one is better to choose? If you are planning to make a pyrolysis boiler with your own hands, then the available options will be limited only by the materials you have, as well as your engineering ingenuity and imagination. We will tell you more about how to make a long-burning wood-burning stove for summer cottages later, but now let's try to give some useful tips to those who decide not to bother and buy a ready-made heating system.

The main parameters that should be followed when selecting the available models of boilers are:

- Restrictions on the budget allocated for the purchase of a gas-generating furnace.

- The area of \u200b\u200bthe house to be heated using a pyrolysis plant. Depending on the characteristics and configuration, long-burning stoves can heat from 80 to 250 square meters of living space.

- Operating time of the unit at full load of fuel. There are three subcategories of gas-generating boilers: with a minimum operating time (up to 4 hours), with an average heating period (up to 8 hours) and, in fact, long-burning stoves (they heat more than 8 hours at one gas station).

- Other technical and functional characteristics of the device.

- Appearance and design of the pyrolysis oven. Functionality and efficiency, of course, are a priority, but do not forget that a gas-generating boiler is also an element of the interior of a house. It is highly desirable that the heating installation harmoniously and naturally fit into the interior of the room in which it is located.

A few words about the main characteristics according to which long-burning pyrolysis boilers are classified. According to the materials of manufacture, they distinguish:

| Cast iron gas furnaces |

| Steel pyrolysis boilers |

| Brick ovens long burning |

The first two are suitable for those who want to get the most compact device, and the last look will appeal to lovers of the classics. Such a brick oven can easily become a highlight in the interior of any home.

According to the method of loading firewood: manually or semi-automatically. The second type will cost more, but will reduce the labor costs for servicing the boiler.

Boiler with automated fuel supply system

Pyrolysis plants can be equipped with various "makeweights", so they should also be classified according to the presence of additional functional units. They can be a hob or a special transparent refractory door that can turn an ordinary solid fuel heater into a full-fledged and aesthetic fireplace.

Naturally, it should be understood that you will have to pay extra for any design and technological delights. It is for this reason that prices for long-burning gas-generating furnaces vary in a wide range from 10 to 100 thousand rubles and more.

Gas boiler with hob

Installation of a purchased gas-generating furnace

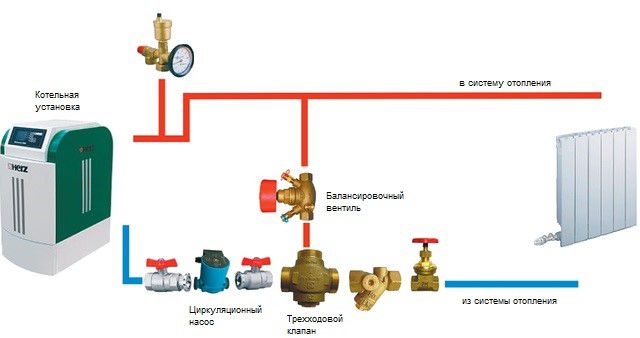

The installation of a ready-made gas-generating boiler of industrial production requires special attention, so we will devote a separate section of the article to this issue. Actually, the general scheme for connecting a pyrolysis furnace with a water circuit looks something like this:

Schematic diagram of the connection of the water circuit of the pyrolysis boiler

It should be noted that this is only one of the many options for wiring the heating circuit.Different manufacturers may offer their own schemes, which will differ in some way. Therefore, in each specific case, carefully study all the technical documentation accompanying the device. As for this scheme, the so-called three-way valve deserves special attention here: it is he who is responsible for mixing hot water into cold water and prevents the furnace from overcooling.

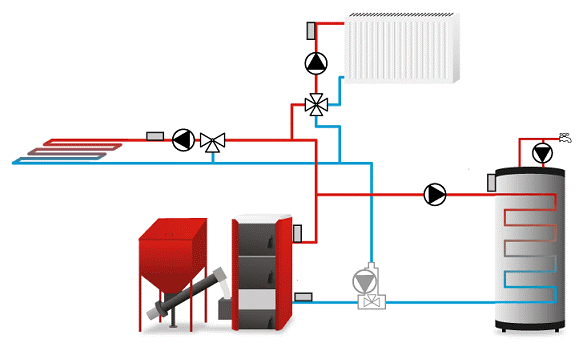

The cold water heating mechanism can be implemented in another way. Below you can see two more possible connection schemes for pellet pyrolysis boilers:

Scheme of switching on a gas-generating furnace with an indirect heating boiler |  Scheme of switching on a gas-generating furnace using a buffer tank |

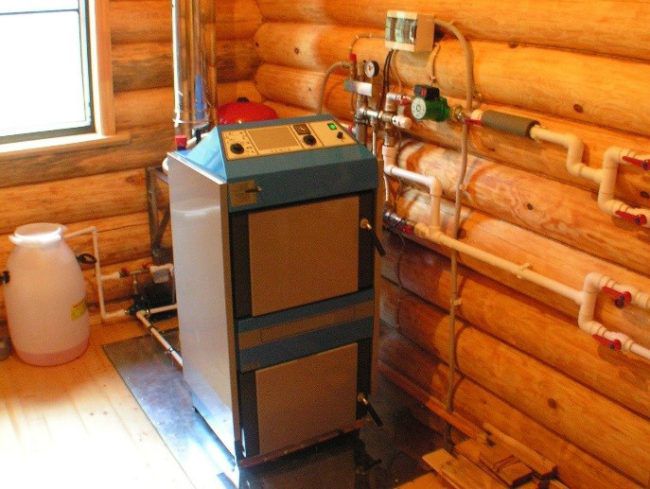

The furnace, in which they plan to place the boiler, must meet certain requirements:

- be spacious and have high ceilings. Preferably from eight square meters; area and with a ceiling height of two and a half meters;

- have a special platform for installing the boiler;

- the ceiling, like the walls themselves, must consist of material resistant to temperature and fire;

- the room must be equipped with at least one window opening;

- the distance from the wall to the front of the boiler should be about two meters;

- it is advisable to overlay the boiler around with an additional brick jacket;

- the room must be equipped with a chimney and a ventilation system (exhaust).

In general terms, the boiler installation algorithm is as follows:

Example of a furnace room | Preparation of the furnace room. We remove all unnecessary and prepare tools and materials for work. |

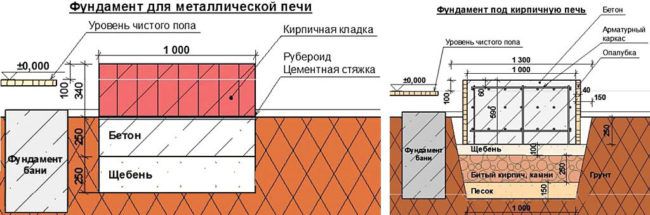

Foundation laying (installation of a concrete slab) for a gas-generating boiler.Preparing the foundation for a purchased furnace is not much different from that for a homemade furnace, we will consider this process in detail below. In general terms, it consists of the following steps:

| |

General schemes of furnace foundations (for brick and metal furnaces) | |

Boiler installed on a tiled foundation | Direct installation of the pyrolysis furnace on the foundation. |

Gas-fired boiler connected to the heating system | Connection to the heating system (piping the water circuit). |

Examples of connecting a gas generating boiler to a chimney | Installation of a chimney and exhaust ventilation system. |

Pyrolysis boiler ready to work | Enabling and configuring relays and boiler automation systems. Trial run and check the system in action. |

Making a long-burning stove with your own hands

We figured out the main guidelines in choosing a ready-made long-burning stove for a summer residence, and now let's find out how to make such an apparatus at home on our own. In the next two sections of the article, we will consider the manufacturing technology of both metal and brick pyrolysis boilers. It should immediately be noted that you cannot do without the minimum skills of brickwork, as well as the ability to work with a welding machine, so get down to business only if you are 100% confident in your abilities.

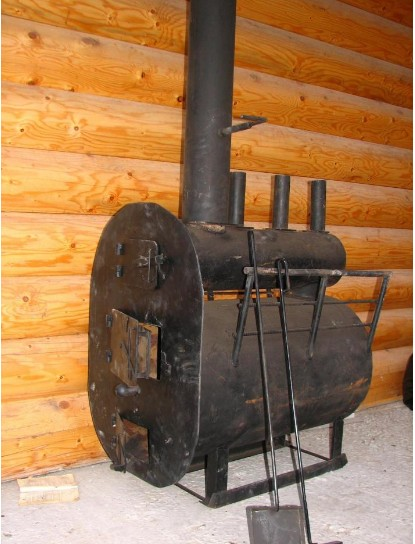

Pyrolysis furnace from improvised means (barrel, cylinder, thick-walled pipe)

The easiest and cheapest way is to assemble a gas-generating furnace from an old cylinder or a metal barrel. Such a device will not differ in a particularly attractive appearance, but it is quite suitable for heating a summer house, garage, utility room or greenhouse. In addition, this type of stove is very mobile and can easily be moved to any other place.

Portable iron barrel pyrolysis oven

Materials and tools for work. Job Requirements

| The basis for our masterpiece of engineering fantasy can serve as: | |

200 liter steel barrel with lid | Volumetric metal barrel. Ideally, it should hold at least two hundred liters, have no external damage and signs of corrosion. The metal must be thick and strong enough. It is advisable to choose steel barrels - this will positively affect the durability of our heater. |

A used fire extinguisher will still come in handy | A good case for a gas-generating furnace will also be a used fire extinguisher or a gas cylinder that has outlived its useful life. Naturally, their dimensions should be comparable to the volume recommended above for a barrel. |

You can breathe new life into a used gas cylinder | The cylinder body is one of the most popular for making homemade stoves. |

A cut of an old pipe is a good case for a homemade stove | In addition, the body of the future stove can be welded from scratch using sheet steel or cuttings of thick-walled pipes. |

| When you make your choice and decide on the body of the future furnace, start looking for additional materials. Namely - the support legs for the heating installation. The easiest solution would be to make supports from: | |

This is what the rebar legs look like | Fittings |

And this stove has tubes welded as legs | Pieces of thin pipes |

The legs of this stove are trimmings of a metal profile (channel) | Scraps of metal profile |

In addition to all of the above, we need:

- Sheet steel, from which we can cut a circle equal in diameter to the body of our furnace;

- Pieces of a metal profile for the manufacture of a clamping piston;

- Stove door, which you can order ready-made or do it yourself;

- Two metal pipes. One with a radius of about 5 centimeters and a height equal to the height of the stove body +15 centimeters from above, and the second with a radius of 7.5-8 centimeters and a length of about 5 m. The first is useful in the manufacture of the pressure piston duct, and from the second we will make a chimney.

Having obtained all the necessary materials, we begin to search for a suitable workplace for carrying out all the necessary installation operations. The room in which we will assemble the stove must meet a number of requirements, namely:

- Have high-quality ventilation so that welding can be used in it;

- Good lighting at any time of the day;

- Have an uninterrupted power supply;

- Possess reliable noise and sound insulation. During the installation process, you will have to use a grinder and welding, and insulation will allow you to interfere with your neighbors to a lesser extent;

- Be spacious enough so that we can safely store all the construction details and tools there;

- Be protected from any atmospheric influences that could damage the metal parts of the oven.

Instructions for assembling a homemade gas generator stove

| The sequence of operations for installing a pyrolysis furnace will look like this: | |

Cylinder with cut off top | We are preparing the body.It will be enough to simply remove the top cover from the barrel, but with a cylinder or a fire extinguisher you will have to tinker a bit. They need to cut off the top. This should be done with the help of a grinder, evenly and accurately. The cut off part will later serve as the main cover of the structure. You should start sawing a cylinder or a fire extinguisher only after you make sure that they are empty and pour water inside. |

Square cases will always be more stable | In case sheet steel was chosen as the basis for the gas generating furnace, remember that square-shaped bodies have better stability than round ones. |

Barrel stoves with rebar legs | Having prepared the body, we proceed to install the legs. They must be welded to the bottom of our homemade heater in such a way that the entire structure on them stands evenly and steadily. The correct installation of the legs can be checked using a plumb line or level. If you made a mistake with the length of any of them, just shorten it with a grinder. |

Piston under assembly | We proceed to the manufacture of the pressing piston-feeder. We cut out a circle from sheet steel with a diameter slightly smaller than the inner diameter of the stove. If the furnace is not round, then we select the dimensions of the piston so that it has a small gap with the inner surface of the housing and moves freely up and down. |

Circle with welded air pipe | In the center of the circle we cut a hole that is suitable for our duct pipe. By welding we connect the circle with the pipe. After that, we check how the piston will go inside the barrel and how much the pipe protrudes from above the body. This height should be about 15 centimeters. |

Clamping vanes at the bottom of the furnace piston | We fix pieces of a metal profile to the bottom of the piston by welding.They will not allow smoldering firewood to "suffocate" and go out, and will also help improve the quality of pressing the logs to each other. |

Cover of a homemade gas-generating furnace with handles | Let's start making the stove cover. If this is a barrel, then the old lid will serve as it. Well, in the case of a cylinder and a fire extinguisher, the previously sawn off upper part will come to the rescue. It is necessary to cut a hole in the lid for the air duct, and it is also desirable to weld handles to it, which will make it more convenient to remove it to load firewood. Remember that the hole should not interfere with the movement of the duct: its pipe must slide freely up and down. Leave a small gap. |

Cut holes for the door | We fix the door to extract the ashes. We cut a hole with a grinder according to the dimensions of the door, weld the hinges and install our hatch. |

The first chimney elbow welded to the barrel | We attach the chimney pipe. A hole for it must be made with a grinder at the very top of the gas-generating boiler body. We weld a piece of the previously prepared pipe under the chimney, given that its smallest length should exceed the diameter of the cylinder body. |

Air duct with damper-regulator | For the chimney and air duct, it is also necessary to design control valves. They will help you manage the draft and the time of the heater on one load of firewood. In the chimney of the gas-generating stove, various condensate is very actively collected. Therefore, the pipe must be protected with heat-insulating materials, cleaned regularly, and a container must be installed at its base to collect the released condensate. In addition, it does not hurt to install a protective umbrella-reflector on the upper part of the pipe, which will prevent atmospheric precipitation from entering it. |

Video.How to make a pyrolysis oven from a gas cylinder

Pyrolysis oven ignition rules

| The process of kindling a gas-generating furnace consists of the following steps: | |

First of all - get the piston | First you need to remove the internal piston-feeder, after removing the top cover of the device. |

Putting fuel in the stove | Next, we put firewood into the combustion chamber, tightly pressing the logs together. Remember that only dry logs are needed to kindle a pyrolysis stove. Otherwise, it can go out at any time. The highest point of loading firewood should be considered the beginning of the opening of the exhaust pipe-chimney. |

Pour a rag with kerosene or liquid for desoldering | We throw a pile of wood chips on top of all the logs and cover them with a rag soaked in fire starting fluid. If there is no flammable liquid at hand, then the rags can be replaced with pieces of paper. |

Furnace closed with a lid | We put the piston with the air duct in place, close our gas-generating stove with a lid. We light a piece of rag and throw it inside through the air duct. Matches in this case will not be able to help us, because they will go out, flying through the pipe. |

| We give the fire about 20-30 minutes for it to flare up. After that, we cover the chimney with a damper so that the firewood stops burning and their smoldering begins. From this moment on, the stove will enter its operating mode, and you will fully enjoy the warmth, comfort and coziness it gives. | |

Tips for operating a gas generating stove

Remember that when placing a long-burning gas-generating furnace in any room, you must strictly adhere to the rules for its use:

- The body of the heater heats up to significant temperatures, so keep away from it any objects that can spontaneously ignite or are sensitive to heat.

- Leave enough free space around the gas boiler. You can’t put furniture next to it, and the walls themselves can also be damaged under its influence. It is advisable to build a special protective brick jacket around the stove. Brickwork will not only protect things around it, but will also help keep the heat in for a longer period.

- When cleaning the firebox of a homemade stove, leave some layer of ash after each time. It will serve as a protective cushion and prevent the lower part of the gas-generating boiler from quickly burning out, which can lead to breakage of the entire device.

Brick pyrolysis oven masonry

A gas-generating furnace can be assembled not only from metal parts, but also laid out with a brick. Before proceeding directly to the consideration of this issue, we will need to understand the meaning of some fundamental terms that characterize the quality of materials for furnace work. Actually, there will be only 3 such concepts: heat resistance, heat resistance and fire resistance.

Long burning brick oven

Heat resistance is the ability of a material to withstand heating to high temperatures and subsequent cooling. During such thermal changes, the substance should not change its structure, geometric shape and chemical composition. At the same time, over the entire range of operating temperatures, heat-resistant compounds must withstand the initial design physical loads and not collapse.

As for heat-resistant materials, their main advantage lies in the ability to maintain the initial mechanical characteristics when heated or cooled. The thermal expansion coefficient of such compounds practically tends to zero.Heat-resistant materials are the basis not only in the furnace business, but also in the production of mechanisms and machines designed to work in extreme conditions.

Refractory substances are heat-resistant or heat-resistant substances that are resistant to aggressive chemical environments. In the furnace business, they are used for the construction of chimneys, the inner surface of which is constantly exposed to gaseous combustion products, often settling during cooling in the form of caustic condensate.

Materials and mortars used for laying various elements of the furnace

Since the individual elements of the furnace structure carry a different functional load, the brick (as well as the mortar) must be selected individually for each of them. Let's consider everything using the example of a classic wood-burning stove.

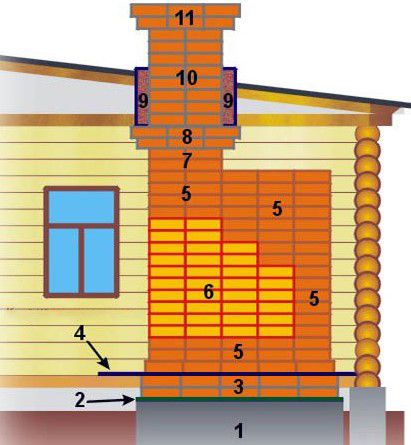

The general structure of the furnace design

- The "pillow" (also called the "root") of the stove is the foundation of the foundation of the reinforced concrete stove. It is poured in such a way as to be mechanically independent of the foundation of the entire building. This condition must be met without fail, since the oven and the house differ in shrinkage rate. Filling is carried out in the usual way, there are no distinctive features in this process.

- A layer of waterproofing material. It can be constructed from an ordinary roofing material, folded in a couple of layers on top of the stove cushion.

- Furnace foundation. Its laying requires a careful and scrupulous approach. An error during the assembly of the foundation will lead to the fact that the entire structure will have to be re-shifted. Solid red brick - this part will not feel a strong temperature effect. Oven mixtures should be used complex, cement-lime, from three components or more.

- Fireproof blind area with a heat-insulating layer. It is made from a mineral sheet of asbestos laid on top of a sheet of iron. The third, upper layer, the construction is completed by a felt cloth treated with clay impregnation (liquid diluted clay, the so-called "clay milk").

- The main part of the “body” of the stove, which acts as a heat exchanger. The operating temperature of this element very rarely exceeds the threshold of six hundred degrees Celsius, however, it is constantly affected by acrid smoke and chemically aggressive compounds contained in its composition that can settle in the form of acid condensate. Therefore, a brick for this part of the stove requires a specialized stove, red, full-bodied ceramic type M. The solution, in turn, is clay, one-component.

- Furnace furnace. In a pyrolysis oven, it will consist of several chambers, each of which is subjected to a very powerful thermal effect. The temperature inside the furnace can have values \u200b\u200breaching up to one and a half thousand degrees. A special brick is needed, the so-called fireclay, and a clay-chamotte mortar is needed.

- "Source" of the chimney pipe. It must withstand the same impacts as the furnace heat exchanger, therefore the materials that must be used for its masonry are similar to those in paragraph No. 5.

- Chimney "fluff" - a structural element designed to provide an elastic connection between the chimney and the ceiling, preventing its possible subsidence. The brick here needs an oven M150, and the mortar is lime.

- Fire separator - a box made of iron, inside of which there is a layer of non-combustible heat-insulating substance.

- The main part of the chimney. They lay it with ordinary red brick, since it is not exposed to strong thermal or chemical influence.The solution is lime type.

- From the same materials, the chimney fluff is also made, which completes the furnace structure.

Preparation of materials and tools for masonry

As it has already become clear to you from what you read above, for oven masonry we will need to stock up on three types of bricks:

- red full-bodied - it will go to the manufacture of the foundation and part of the chimney

- red ceramic furnace M150 - for assembling the main part of the furnace body

- fireclay for laying combustion chambers

Further, we cannot make the foundation of the furnace without cement. Accordingly, it also needs to be purchased. In addition, we additionally buy roofing material, a sheet of steel and various auxiliary furnace fittings: doors for adjusting the air supply, a hatch for loading firewood, etc. The amount and type of materials chosen will depend on the particular stove laying scheme that you choose for yourself. We will consider one of them in our article, but you should not limit the flight to your engineering fantasy only within the framework of a single instruction.

As for furnace solutions, it is quite possible to prepare them yourself. This process is quite laborious and takes some time, however, it allows you to save a lot on materials and reduce the final cost of creating a brick pyrolysis furnace. In more detail and with all the necessary instructions, this issue is discussed in the article. Brick mortar for kiln proportion.

Of the tools we will need:

- Master OK

- Roulette

- Building level and plumb

- A hammer

- Tanks for the preparation of furnace solutions and pouring the foundation

- Shovel

- Sieves for sifting sand and straining clay

Making the foundation of a brick gas-generating furnace

Long-burning furnaces are distinguished by the fact that they must quickly warm up and go into operation within a minimum period of time. For this reason, it is necessary to place the foundation of the gas-generating stove at least at a distance of 70 or more centimeters from the foundation of the building itself. In addition, it is desirable to fill the gap between both foundations with sand.

| The process of creating a furnace base consists of the following steps: | |

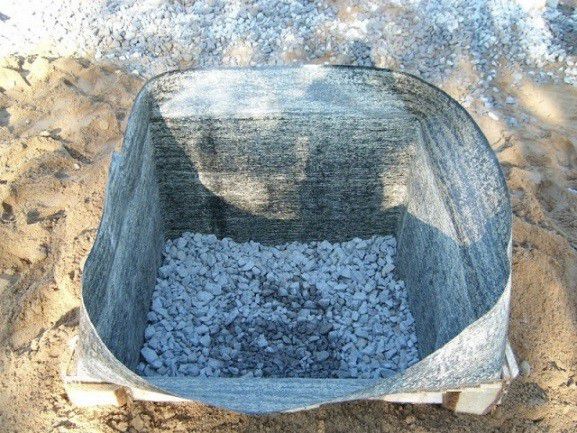

Pit under the foundation of the furnace | Digging a hole for the foundation. It should exceed the dimensions of the oven by 10 centimeters in each direction. According to our specific ordinal scheme, this is approximately 1.20 m by 85 cm. The depth of the pit should be 70 centimeters |

Foundation waterproofing | We put a bitumen-based waterproofing layer on the bottom and sprinkle it with a layer of sand about 10 centimeters high. |

Backfilling of rubble | On top of the sand we impose a layer of broken brick or rubble, on top of which the base of the furnace foundation will be located directly. |

Foundation formwork | We build formwork from boards and a reinforcing cage, fill it all with concrete. |

Waterproofing with roofing material | After waiting for the solution to dry, we place a layer of roofing material waterproofing on the concrete base. Then we lay out the foundation of the stove in two layers of solid red brick on top, checking the quality of the masonry with a level. |

Stove with fire protection | We complete the structure with a fireproof blind area and thermal insulation made of asbestos and steel sheets, covered with felt soaked in clay milk. |

We strongly do not recommend using silicate brick for laying the foundation, as it is sensitive to high humidity and temperature changes.

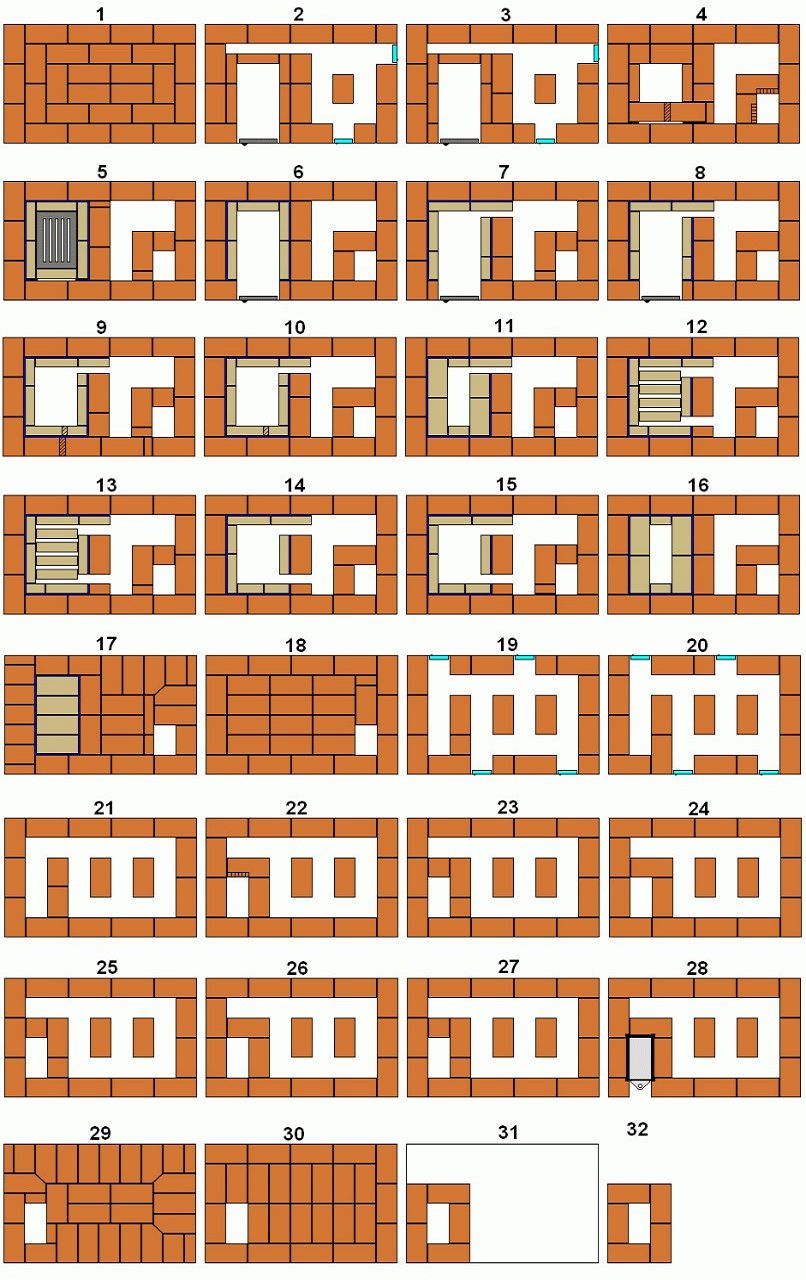

Basic rules for laying a pyrolysis oven. Ordinal scheme

When proceeding directly to the laying of a gas-generating furnace, remember that you must strictly adhere to the following rules:

- Each of the elements of the furnace must be assembled from the appropriate type of brick, which will withstand all temperature and chemical influences. We have already written about this above.

- Laying should be carried out clearly according to the chosen order plan in order to avoid mistakes and the need to redo the work again.

- Every 2-4 rows, be sure to check the quality of the masonry with a level or plumb line. You don't want the oven to be crooked, do you?

- In each row (as well as between rows), it is necessary to perform a complete dressing of the seams.

- The width of the joints in a homogeneous brickwork should be about three millimeters. At the joints of fireclay and red bricks, the size of the seams must be increased to six millimeters. The same rule applies to connections between bricks and steel elements.

- Seats for various doors and latches should be made with a small margin, taking into account the possibility of thermal expansion of parts. Asbestos gaskets, or intermediate layers of special building mixtures based on sintering compounds, must be placed between metal and brick. For example, you can use fireclay or silicone for fireplaces - these materials can withstand strong heat and, at the same time, ensure the tightness of all joints of the body and stove fittings.

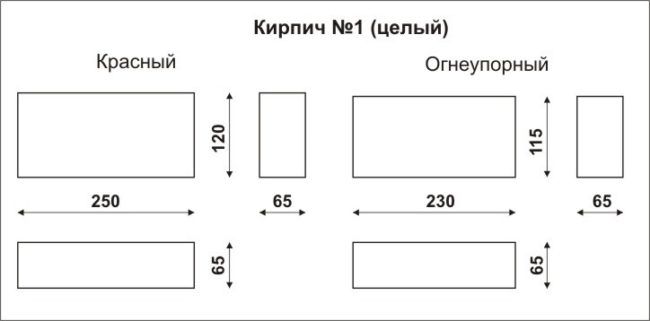

Finally, as an example, we will give you one of the possible ordinal schemes of long-burning furnaces. Naturally, before starting construction, you must definitely evaluate the dimensions of the room and the size of the space that is planned to be allocated for the gas-generating boiler. In accordance with these initial parameters, you should choose the scheme that suits you.It will be quite easy to estimate the dimensions of the future heating installation, because the dimensions of one brick are standard and are 25x12x6.5 centimeters for a solid red brick.

Brick dimensions

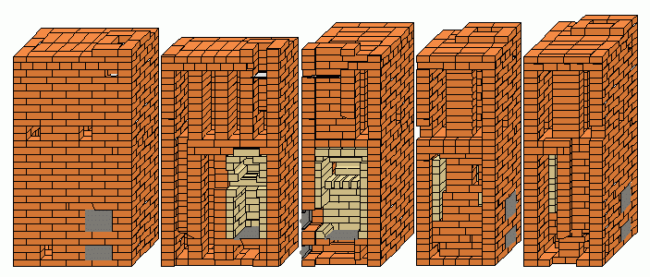

Ordinal scheme of laying a long-burning furnace:

The appearance of the finished long-burning brick oven, assembled according to the scheme:

As an added bonus, we also suggest that you familiarize yourself with the video, which shows one of the possible options for making a brick pyrolysis oven on your own. The author demonstrates step by step each stage of the furnace masonry, and also makes a practical test of his device in action.

Video. Do-it-yourself long-burning brick oven