They say that all new items are well-forgotten old ones. The creation of heating systems based on pyrolysis combustion is no exception. The first plants using pyrolysis technology were built back in the 70s of the 19th century before last.

Until now, this technology is widely used both in our country and abroad for oil refining. Actually "pyrolysis" is the process of chemical decomposition of organic matter under the influence of high temperature. In devices using solid organic fuel (usually wood), the solid part and the gases released from it during thermal decomposition burn separately, which significantly increases the efficiency of such boilers.

Despite the complex name and intricate description of the process, you can easily build a pyrolysis boiler with your own hands, for this you will need sheet steel, a welding machine and drawings that you can take on our website.

Content

The essence of the pyrolysis process

In pyrolysis boilers for solid fuels, such types of organics are used, which, during thermal decomposition, give a large yield of volatile combustible substances.Such boilers work not only on wood (and all types of fuel made from wood, such as pellets or fuel briquettes), but also on coal, up to coking grades, the combustion temperature of which reaches very high values!

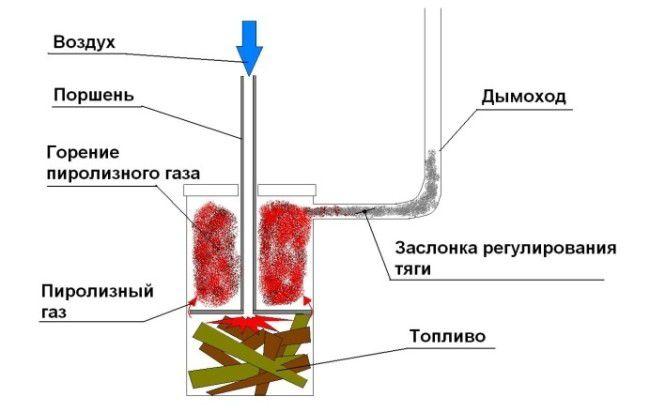

Fuel in pyrolysis boilers is placed on the grate. After igniting the loaded batch of fuel, the tight door closes and the smoke exhauster starts to work. As a result, a high temperature rises in the combustion chamber, up to 800 degrees, but there is no oxygen from the air for normal intensive combustion. Instead, fossil fuels smolder and char, releasing volatile gases, predominantly hydrocarbons.

Under the action of convection, volatile combustible gas enters the grate space. Together with them, nitrogen also migrates, which is in the primary air in the furnace. Under the grate of the grate, oxygen from the secondary air supply circuit is mixed with the gas mixture. The resulting mixture already has the ability to burn. It burns out, performing a useful function (for example, heating water in a heat exchanger), and in addition, the released heat goes back to the fossil fuel and supports the smoldering process.

Main characteristics of pyrolysis boilers

The main features of boilers operating on pyrolysis technology are the following:

- Possibility of manufacturing from inexpensive structural materials.

- Long time of one pyrolysis cycle, reaching about 30 hours,

- Complete explosion and fire safety.

- Simplicity of design, available for self-manufacturing.

- A wide range of wood fuels used (from classic firewood to pellets).

- High environmental friendliness of boilers, low amount of combustion products.

How often do you need to throw firewood?

In a conventional furnace, you will have to load fuel at least every two hours. The reason for this is the high intensity of fuel combustion in furnaces of this design. Most of the heat in this case literally "flies into the pipe." The efficiency of such boilers is minimal, in addition, there are a lot of residues in it that have to be regularly raked out.

But if you limit the flow of oxygen, then the burning period increases significantly. In this case, heat is released not only during the smoldering-pyrolysis process itself, but also from the combustion of the evolved gases. As a result, the operating time from one load can increase up to a day or more.

DIY pyrolysis boiler manufacturing process

We note right away that pyrolysis boilers can be used not only for heating. But also for direct heating of small rooms, such as a shed with livestock or a garage.

Nuances with fuel

Good news for car owners: your boiler can be “fed” not only with firewood, but also with used engine oil. The price of such fuel is simply ridiculous, and in a pyrolysis boiler it will burn no worse than ordinary firewood. But there is a nuance: the boiler, "eating" mining, must have a special design.

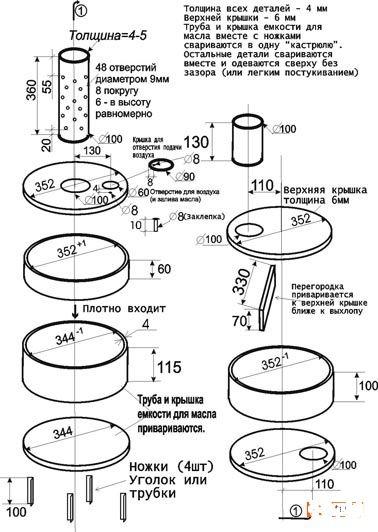

Scheme of a pyrolysis boiler for mining

To create such a boiler is very simple. It has two containers: the lower one, into which fuel is loaded and where the pyrolysis process actually takes place, and the upper air chamber.

A pipe with thick walls is welded into the lower part, in which holes are made.Actually, in this pipe, the afterburning of vapors from the "working out" takes place.

Partitions are mounted in the upper air chamber, which direct hot air along a winding route, thereby achieving increased heat transfer from the upper chamber to the room.

Through the chimney welded to the upper chamber, combustion products are removed into the atmosphere.

Such an oven can be improved somewhat. To do this, a refueling tank is mounted next to the lower tank, connected to it by a pipe. Refueling takes place on the principle of communicating vessels.

But, pay attention, it is strictly not allowed to get water into such a stove. It should not be placed in a place where precipitation is possible. When water enters, the smoldering oil foams and expands sharply in volume. This can even lead to a break in the structure.

Also, when creating such a furnace, please note that the height of the chimney must be at least two meters.

If you equip the upper chamber of such a furnace with a water jacket, then it may well heat the flow of water passing through it. Also, the upper tank can heat the passing air.

Pyrolysis boiler for wood waste

Perhaps you have accumulated a lot of wood waste on the site: chips, sawdust, shavings. In order to effectively burn such "garbage" you can build a special boiler. Such a device will also become an indispensable assistant in woodworking shops.

To create such a furnace, a minimum of materials is spent and its design is extremely simple.

Stock up on the following materials:

- A metal barrel with a capacity of 200 liters, from which you need to cut the top cover.

- Ribbed lid that fits exactly to the mouth of the barrel.

- Round piston with a section slightly smaller than the internal section of the barrel. It must be made from a massive workpiece or artificially weighted.

- A pipe with a cross section of 10 centimeters and a length of 20 centimeters more than the height of the barrel.

- A chimney with a cross section of about 10 centimeters and a length of at least 40 centimeters.

In a tightly fitted outer cover, a hole is cut out with a cross section slightly larger than that of the pipe indicated in paragraph “4”, it is also the “air pipe”. The chimney pipe is welded into the upper part of the side surface of the barrel.

The air pipe is tightly welded to the piston. At the upper end of the air pipe, a movable damper is placed that regulates the volume of air supplied. We weld ribs to the bottom of the piston, which will tamp the fuel mass.

We put any dry wood fuel into the barrel. You can ship anything, up to paper and cones. It should be noted that the dryness of the initial fuel is very critical for pyrolysis boilers. We fill the barrel to 2/3 of its height. We put chips or paper on top of the firewood and set fire to them. It is not forbidden to splash a few drops of gasoline. After the fuel has ignited, we insert the piston with the air pipe, close the barrel with the top lid. The fuel will gradually burn out and the piston will lower under its own weight.

Due to the weight of the piston and without sufficient access to oxygen, the fuel in the barrel will slowly smolder.The gas released during pyrolysis will penetrate into the upper part of the barrel, where it will also burn. The upper part of the barrel will heat up the most, in this part the air temperature can reach 900 degrees. This temperature completely burns out even soot.

With good adjustment and dry fuel, such a pyrolysis stove can continuously work on one tab for up to 30 hours.

Horizontal version of the pyrolysis boiler

A 200-liter metal barrel can also be turned into a horizontal boiler. As well as the vertical version - in such a furnace there will be a smoldering chamber and an afterburning chamber for the gases released.

In principle, such a boiler can be purchased in a ready-made form. Modern industry offers a lot of options for such devices for every taste and budget.

Additional equipment for pyrolysis boilers

In addition to heating the surrounding air, pyrolysis boilers can perform many other useful jobs. First of all, of course, they can be connected to heating systems with air or liquid coolant.

So, convection ovens are very popular. They use the principle of air convection. For this, special curved air ducts are placed on the boiler. Their lower nozzles take in cold air, and hot air comes out through the upper nozzles.

And of course, no one bothers you to equip any boiler with a heat exchanger pipeline that will heat water for a heat supply system or for a domestic hot water supply system.

And in conclusion, you can watch a short video tutorial describing the manufacture and operation of the pyrolysis boiler.

Video: Do-it-yourself pyrolysis boiler