In the cold period of the heating season, the issue of space heating becomes more relevant than ever.

Do-it-yourself bubafonya oven: diagram and drawing

And if in city apartments, as a rule, housing and communal services are responsible for this, then residents of the private sector have to deal with all the problems that arise on their own. For a conventional wood-burning stove, it is necessary to purchase a significant amount of logs and often this seriously hits the pockets of consumers.

In addition, some people need to heat not only residential, but also auxiliary premises, such as garages or greenhouses. Therefore, there is a natural desire to find a way of the most economical and efficient heating.

Content

- What is a long burning stove? On what principle is its work based?

- The history of the creation of the pyrolysis furnace "Bubafonya"

- The internal structure of the long-burning furnace "Bubafonya"

- Advantages and disadvantages of the pyrolysis oven

- Making the oven yourself

- Ignition of the stove "Bubafonya"

- Recommendations for increasing the efficiency of a homemade stove

What is a long burning stove? On what principle is its work based?

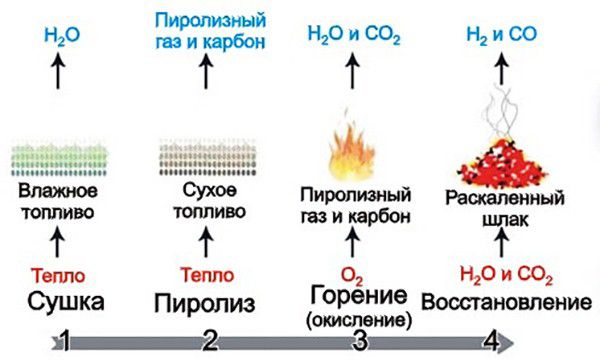

To begin with, we need to understand how wood burning actually occurs. In order for wood to ignite, it must first be heated to a temperature of about one and a half hundred degrees from an external heat source. As a rule, this task is performed by paper or wood chips set on fire with a match. The tree begins to slowly char and, upon reaching a mark of about 250 degrees, decomposes into simple chemical components. The white smoke that we can observe when kindling a fire is gases and water vapor released by heated wood. And now, having stepped over the level of three hundred degrees, the gaseous substances released from the tree ignite, contributing to the further acceleration of the thermochemical reaction.

In itself, the decomposition of fossil fuels, such as, for example, wood, into simple elements is called pyrolysis. And everything would be fine, but the usual burning of wood does not fully use all the potential inherent in the energy carrier. There is a lot of waste left, which, in the end, does not contribute to savings.

Pyrolysis ovens, one of the variants of which we will consider in this article, use fuel much more efficiently. The main secret is that the combustion of gases released during heating of wood occurs separately from the energy carrier itself. At the same time, the primary fuel slowly smolders, which makes it possible to achieve much longer work time on one log load. In furnaces of the “bubafonya” type and other pyrolysis heating devices, everything burns out almost 100%, leaving only a small amount of ash after.

How combustion occurs

The history of the creation of the pyrolysis furnace "Bubafonya"

For the first time, a “bubafonya” was assembled by a folk craftsman named Afanasy Bubyakin, who lives in Kolyma. In fact, it was named after him. The craftsman took the Stropuva pyrolysis boiler, made in Lithuania, as the basis of his product. Athanasius simplified the design as much as possible so that it could easily be repeated independently. That is why the home-made pyrolysis furnace "Bubafonya" is famous for its fairly high popularity.

It should immediately be noted that, since a home-made heater is made from available improvised materials, it rarely has an attractive and aesthetic appearance. The main advantage of bubafoni is its simplicity, reliability and efficiency.

Below you can see an example of a homemade stove designed by Afanasy Bubyakin, made from an old gas cylinder.

Two furnaces "Bubafonya" from cylinders

The internal structure of the long-burning furnace "Bubafonya"

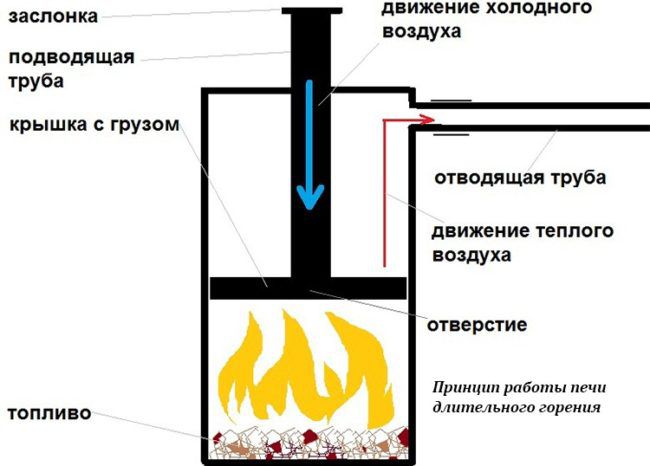

- The main element in the design of "bubafoni" is its body. As a rule, it has a cylindrical shape: a cylinder, a large fire extinguisher, a barrel or a thick pipe with a welded bottom.

- Chimney for the removal of waste products of combustion. It is made, in most cases, from a metal pipe 11-25 centimeters in diameter, welded to the top of the body.

- Piston feeder. It is a metal circle with ribs welded on the lower part, in the center of which an air duct pipe is fixed. The ribs allow you to create an additional air gap between the piston and the logs, which has a positive effect on the smoldering process and the activity of the release of pyrolysis gases.

- Regulating valve, which allows you to control the supply of oxidizer inside the furnace.

- Cover with an opening for an air duct. Together with the piston, it forms a secondary combustion chamber, in which pyrolysis gases are ignited.

Schematic diagram of a homemade pyrolysis furnace "Bubafonya"

Advantages and disadvantages of the pyrolysis oven

First of all, it should be noted the positive qualities of this heater:

- "Bubafonya" has a very simple design. Owning a welding machine and basic skills in working with metal, anyone can easily and simply make a furnace with their own hands.

- The pyrolysis stove "Bubafonya" is not picky at all in terms of choosing a solid fuel energy carrier. It will burn properly on wood, coal, sawdust, chips and other wood waste. In addition, it can be loaded with pellets - an inexpensive and environmentally friendly granular fuel.

- Working hours. The pyrolysis oven after one load of firewood can continuously function and heat the air in the room up to 24 hours. This indicator, however, can vary significantly, depending on the volume of the chamber, the rate of supply of the oxidizer and other parameters.

But you have to pay for everything, and therefore the simplicity of the internal structure of the Bubafonya oven leads to some disadvantages:

- "Bubafonya" does not have high performance in terms of efficiency. This is due to uneven heating of the cylinder body (barrel) and lower heat transfer. Pyrolysis furnaces of more complex and advanced designs, in turn, can boast excellent performance in terms of efficiency, almost reaching a value of 90%.

- "Bubafonya" is rather inconvenient to clean from the remnants of combustion products: the ashes and ash have to be taken out through the top.However, this home-made heater can be improved by welding a door at the bottom, which makes it easy to remove everything superfluous from the bottom of the furnace.

- aesthetic unattractiveness. The design is rather rough in appearance and is unlikely to become a decoration of the interior of the room in which it will be installed.

Making the oven yourself

The whole process of creating a home-made pyrolysis boiler "Bubafonya" can be divided into five main stages:

- Preparing the premises, materials and tools for work

- Installation and assembly of the structure

- Chimney arrangement

- Laying the foundation for a pyrolysis oven

Let's look at each of them in more detail.

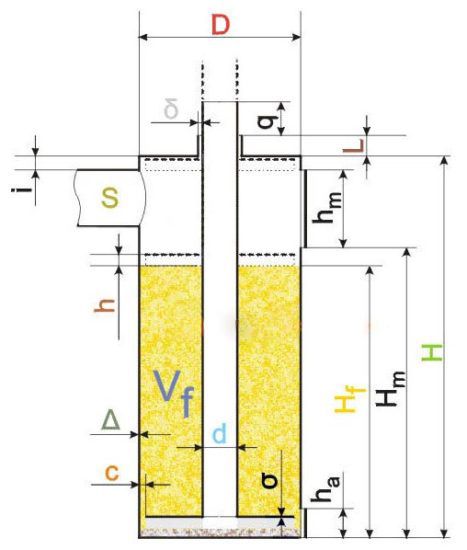

Drawing pyrolysis furnace "Bubafonya". Calculation of the main proportions.

The fundamental proportion in the process of constructing a home-made pyrolysis furnace from a gas cylinder is the mathematical ratio of the inner diameter of the body to its height. In the drawing, the diameter is indicated by the letter D, and the height is H. The ratio of H to D should be in the range from three to five to one. The diameter itself under optimal conditions will be about 30-80 centimeters. A furnace body smaller than 30 centimeters should not be chosen, since the oxidizer will pass through the combustion chamber too quickly without fully reacting with the fuel. This will greatly reduce the efficiency of the device. A diameter of more than 80 centimeters is undesirable for another reason: in such a boiler, firewood burns very slowly at the edge, and faster in the center. When the fuel burns out, a hole will form into which the piston will fall, which will lead to the extinction of the bubafoni.

Calculation of the proportions of the elements of the pyrolysis furnace "Bubafonya"

Wall thickness Δ is the second most important calculated value.For optimal heat transfer, a 4-5 mm steel case is perfect. A smaller wall thickness will significantly reduce the life of the heater and the time of its operation on one gas station.

Dimensions of the pressing piston pancake:

Gap With between the piston and the inner surface of the body is optimally calculated equal to 0.05*D. Accordingly, the diameter of the pancake itself will be calculated by the formula d \u003d D-2 * H

The height of the pressing ribs from the metal profile is considered more difficult. Here, the dependence between the parameter values is non-linear. Empirically, for furnace body diameters from 60 to 80 centimeters, this number is taken equal to 0.1 * D. For the smaller bubafoni, we use the proportion equation, taking into account that with D0=30 cm h0=4 cm.

Proportion calculation example. The inner diameter of the balloon is 40 cm. We consider the required height of the channels as follows: h = D * h0/D0=4*40/30=5.3cm

Pancake thickness σ. This parameter is inversely proportional to the inner diameter of the "bubafoni" D. It is necessary that the piston with optimal force presses on the fuel layer. If the pressure is low, the reverse action coefficient of the furnace will decrease and there will be a risk of the boiler burning back, followed by smoke escaping through the duct. A piston that is too heavy, in turn, will not leave an air layer sufficient for smoldering firewood and the “bubafon” will go out.

This value can be found using the table below. There are no special requirements for compliance with this parameter, it is enough to adhere to it at least approximately.

Calculation of the minimum required chimney area. The smallest allowable value of the area S of the pipe is calculated based on the maximum energy output of the fuel per hour. S(cm2)=1.75*E(kWh). In this case, E \u003d m * q where m is the mass of loaded fuel, which can be found by multiplying the maximum bookmark volume V \u003d Hf*(π*D2/4) on its density (we learn from the table below). The coefficient q, in turn, is the specific energy of combustion per unit volume of fuel per hour (we also take it from the reference table).

| aspen logs | ||

| Coniferous shavings (sawdust) | ||

| Briquettes from alder | ||

| Coal | ||

| Peat |

Calculation of the air intake diameter

Knowing the dimensions of the chimney pipe, it will not be difficult to calculate the diameter of the piston duct. This value, denoted as d, is equal to half the value of the square root of the ratio 4S/π.

Preparing the premises, materials and tools for work

Since the assembly of bubafoni requires the use of a welding machine, not every room is suitable for us to work. Be sure to need high-quality ventilation, uninterrupted supply of electricity and reliable wiring (welding work can cause overload in the circuit). In addition, installation can take more than one day, so the room must be protected from the effects of precipitation and be spacious enough. Good soundproofing of the workplace is also important, since the noise from the grinder, welding and other tools is unlikely to please your neighbors.

Having chosen a suitable place for installation, we proceed to the preparation of materials.

- The basis for the pyrolysis oven will be an old gas cylinder.Instead, you can also use a voluminous (about 200 l) steel or cast iron barrel with strong walls without signs of corrosion, a large spent fire extinguisher, or even a metal pipe with a steel circle welded on the bottom.

- Next, we need blanks for the supporting "legs". In principle, you can try to do without them, but the “bubafonya” on legs will be much more stable, it is more difficult to accidentally turn it over with an awkward movement. Supports can be made from metal profiles, fittings and even pieces of steel tubes.

- "Handles" for more convenient carrying of a home-made stove, we can also create from scraps of fittings. Also, they will not be superfluous on the bubafoni lid: this will greatly simplify the process of loading firewood and cleaning the boiler from ash.

Various options for homemade stove legs

Armature legs

Pipe legs

Metal profile legs

Auxiliary materials for creating "bubafoni" will be:

- Sheet steel for the manufacture of the piston;

- Two metal pipes for the chimney and air duct. The optimal diameter of the air supply pipe is about 85-100 mm, and its length should be about 150 mm longer than the height of the cylinder. The chimney will require a wider pipe, with a diameter of about 150 mm. As regards its length, it must be at least equal to the cross-section of the cylinder;

- Metal profile (channel);

- Crushed stone, concrete and refractory bricks for the manufacture of the foundation;

The list of required tools will be small. We will use:

- hammer;

- Vise;

- shovel;

- Mastercom;

- Portable apparatus for electric welding with a set of electrodes;

- Bulgarian for cutting parts;

- Roulette, pencil, plumb and level;

Installation and assembly of the structure.Chimney arrangement.

- First of all, we make a neat cut in the upper part of the balloon. The resulting cap will serve us later as a cover for the furnace.

Blank for the cover of the pyrolysis furnace "Bubafonya"

- We fix home-made legs to the bottom of the cylinder by electric welding. The correctness of their installation can be checked using a level or plumb.

- The manufacture of the bubafoni piston takes place in three stages:

- First, cut out a circle from steel. Its transverse dimensions should be less than the inner diameter of the gas cylinder by about 3.5-4.5 cm in order to ensure free exit of the resulting pyrolysis gases into the secondary chamber. In the central part of the circle, we make another hole so that the end of the duct pipe can be tightly inserted.

Blanks for the piston-feeder

- We weld together a circle and a metal pipe.

Air duct welded to the base circle

- On the basis of the blank for the piston we fix the channel trim by welding.

Pieces of metal profile fixed on the reverse side of the piston

The finished product will look something like this:

Pyrolysis furnace piston assembly

- We design the furnace cover. In the center of the cut off upper part of the old gas cylinder, we mark the hole. This must be done in such a way that the duct pipe with a fixed supply piston can move freely in it. According to the markup, we make the necessary cut. On the sides of the improvised cover, we weld handles from pieces of reinforcement bent with a vice and a hammer.

Bubafoni cover. Instead of fittings for handles, metal rings were used.

We mount a chimney in the upper part of the impromptu pyrolysis furnace.With a grinder, we cut a neat hole according to the size of the billet pipe and fasten it together by welding.

Video: How to cut a smooth hole under the chimney grinder.

Chimney welded at the top of the cylinder

To ensure better draft, the chimney should consist of two "knees" connected at a right angle. To do this, at the ends of the horizontal pipe coming out of the cylinder and another segment of the same diameter, we make even cuts with a grinder at an angle of 45 degrees and weld the pipes to each other.

The appearance of the chimney

In addition, it is highly desirable to provide protection for the chimney in the form of a special reflector cap. This will prevent the penetration of moisture and precipitation into the furnace with its subsequent attenuation.

The appearance of the reflector for the chimney

On this, the main part of the installation work can be considered completed. The oven is now fully operational. We can only, if desired, equip a special foundation for it and begin direct operation.

Laying the foundation for a pyrolysis oven

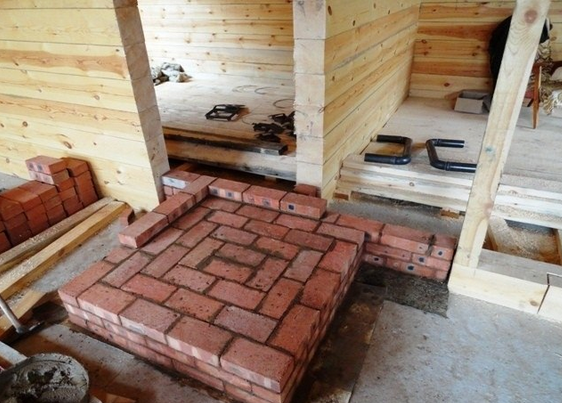

The work on arranging the foundation for the bubafoni will take place in three stages:

- First, we need to dig a square-shaped hole about one and a half meters in size. The optimal depth for the foundation will be approximately 20-30 centimeters.

Pit under the foundation for the furnace

- We fall asleep crushed stone inside and fill it with concrete mortar on top. The surface is leveled with a trowel. After drying, we check the quality of the resulting plane with a level and further correct it, if necessary.

Concrete-filled stove foundation

- When the concrete is completely dry, lay several rows of refractory bricks on top of the base.As a rule, two or three brick layers will be enough.

Fire-resistant brick laid on the basis of the foundation of the furnace

Ignition of the stove "Bubafonya"

We take out the piston-feeder with a welded air duct from the inside, having previously removed the cap from the cylinder.

We put wooden logs inside. They must be placed horizontally butt to each other. The vertical placement of firewood can have rather unpleasant consequences if an unburned log standing on an edge prevents the piston from moving. This will lead to the fact that instead of smoldering, a full-fledged fire will flare up in the primary chamber. As a result, the correct mode of operation of the stove will be violated, the firewood will burn faster and, in addition to everything, it may begin to smoke through the duct. Logs must not be laid above the location of the chimney.

Laying firewood in the pyrolysis oven

Pour chips with sawdust or small branches on top of the wood bookmark. Soak a piece of old fabric in a kindling liquid (kerosene is also fine) and put it on a layer of wood chips. Paper can serve as an alternative to a rag.

Processing the top layer of the bookmark with kerosene

We press the bookmark with a piston and put the furnace cover back on.

Installing a piston with a cover

We set fire to firewood by throwing a piece of lit rag or paper inside through the duct-duct. A bubafoni match is not suitable, because it has time to go out before it falls down.

Ignition of the furnace

After 15-25 minutes, after the bookmark flares up well, it is necessary to close the valve on the air duct. This will restrict the air supply to the primary combustion chamber and cause the logs to smolder, releasing pyrolysis gases. Thus, the bubaphone will switch to its main operating mode.

Video instruction. Ignition of the stove "Bubafonya"

Recommendations for increasing the efficiency of a homemade stove

The main problem affecting the efficiency of the bubafoni is the uneven heating of its body and, as a result, the deterioration of the heat exchange process with the environment. Partially it can be solved with the help of a fairly simple refinement of the design.

To carry out the modification, we need a corrugated metal profile sheet. It is necessary to make a kind of “shirt” for the furnace out of it, tightly fixing it on the surface of the cylinder by welding or in another accessible way. Such an improvement will contribute to the formation of ascending convection air currents: cold air is drawn in from the bottom of the fins, and hot air is released from above. In addition, you can additionally overlay the entire structure with bricks. Such a step will allow the walls around the stove to accumulate the heat radiated by it, heating the room more evenly and longer.

An improved version of the bubafoni. Instead of a corrugated profile, segments of profile pipes were used.

Video instruction. Making a homemade pyrolysis-type stove "Bubafonya" on your own