With the onset of the first winter cold, gardeners, beekeepers and garage owners face the issue of freezing stored supplies, personal cars, heating greenhouses, beehives and similar structures.

At the same time, cost-effectiveness, the duration of fuel combustion without additional reloading, environmental friendliness, safety, efficiency, small dimensions and simplicity of design become important criteria.

Content

Who invented the oven?

The first furnace was designed, assembled, tested and shared with Internet users by Afanasy Bubyakin, a craftsman from the city of Kolyma. On the World Wide Web, Athanasius appeared under the pseudonym "Bubafonya" (bubafonja), thanks to which the proposed design of a long-burning heating system got its name. The designer himself admitted that he was inspired to create the furnace by the Lithuanian Stropuva boilers, which have a similar principle of operation.

What is the Bubafonya oven

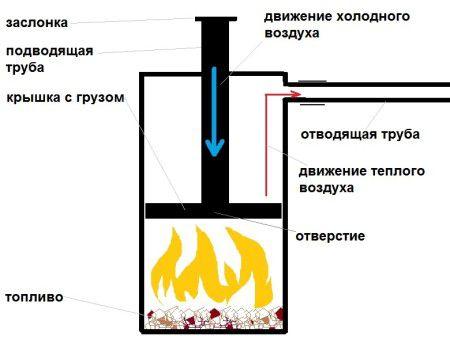

The Bubafonya stove is made practically from improvised materials.The design is based on a cylindrical container or simply a metal barrel or a piece of pipe of sufficient diameter with thick walls welded at one end. The bottom of the container is sealed, and the top of the barrel is closed with a lid. A piston with a load (welded sections of a channel or metal corners), air dividers and a supply pipe are installed inside. A discharge pipe is welded to the upper part of the fuel tank (barrel) body. It is connected to the main pipeline by means of a clamp and fiberglass, which serves to reduce heat loss.

For ease of use, metal handles are welded on the lid and outer walls of the fuel tank.

Design advantages

- compactness;

- low cost of construction and fuel;

- speed and ease of assembly;

- sufficiently long operation of the furnace without additional reloading of fuel;

- the ability to assemble the structure of the required dimensions with your own hands;

- environmental friendliness;

- high efficiency;

- autonomy, that is, the ability to work without electricity;

- ease of operation (pipes from condensate are cleaned with the usual "ruff");

- the ability to quickly replace worn parts;

- the ability to regulate fuel consumption and combustion intensity;

- the possibility of modifying the furnace and connecting it to a water heating system.

Furnace Disadvantages

- formation of condensate on pipes;

- possible freezing of pipes;

- it is inconvenient to remove ash and ashes from the bottom of the fuel tank, as a result they sinter into a mass similar to asphalt and the furnace will eventually require the replacement of the fuel tank;

- sometimes "backburning" occurs when gases enter the room, which sometimes requires the installation of a blower fan;

- cools down quickly after use.

The principle of operation of the Bubafonya furnace

Combustion occurs from top to bottom. Solid fuel loaded into the metal body of the furnace burns out under the action of air draft. In turn, the thrust is created by a pipe welded to the top cover. This cover with a load under its weight slowly falls down during the combustion of fuel, and warm air, rising up, enters the outlet pipe connected to the main pipeline.

The upper supply pipe is covered with a damper, adjusting the gap, respectively, adjust the amount of thrust. Thus, if the air draft is large, then the combustion of the fuel will be very intense, with a large release of heat, but the duration of combustion will be reduced from this. On the contrary, by reducing the gap to such a value that combustion turns into smoldering, it is possible to achieve a sufficiently long (from six to sixty hours) operation of the furnace without additional additional fuel loading.

Rules for the operation of the furnace "Bubafonya"

In order to kindle fuel in the stove, it is necessary to load small firewood on the bottom of the fuel tank, add a layer of wood chips, paper on top and light the fire with matches. After that, a piston with a load is installed in the fuel tank, the lid is closed and the gap between the damper and the supply pipe is adjusted.

Safety

- It is not recommended to place flammable liquids, paper, rags, furniture, etc. close to the oven.

- It is necessary to load fuel in protective gloves.

- When igniting, it is not recommended to use kerosene, gasoline, acetone and other flammable liquids.But if this is indispensable, then the liquid is first added to the firewood, then they are loaded, and only after that they kindle a fire, carefully making sure that mittens or clothes do not ignite.

- If cooking is planned on the stove, then this must be done only after the stove has completely warmed up, not earlier than fifteen minutes after ignition.

- It is possible to touch the heating parts of the operating furnace only in protective gloves.

- To extinguish the furnace, it is necessary to completely block the access of oxygen (close the valve on the inlet pipe) and wait until the combustion stops. If this process needs to be stopped immediately, then fire-fighting agents are used.

- It is not recommended to burn plastics and household waste in the oven, as poisonous gases are released and soot is deposited on the pipes of the system.

- Firewood is chosen in proportion to the dimensions of the fuel tank. At the same time, it should be remembered that damp or tarry wood interferes with combustion, forms condensate and deposits on the working elements of the furnace.

- It is forbidden to paint the heating parts of the furnace with varnishes and enamels. With an increase in temperature, the paint can emit fumes that are unsafe for humans and even ignite. For painting it is allowed to use only heat-resistant paints.

- It is necessary to install the stove on a layer of non-combustible material (iron, concrete, etc.).

Modernization of the furnace "Bubafonya" and increase in efficiency

The Bubafonya stove is successfully used not only for heating residential and non-residential premises, but also successfully used in conjunction with a water heating system.

To do this, a water “jacket” is built around the fuel tank, to which heating pipes are connected.Thus, the heat generated in the furnace, through the metal walls of the fuel tank, heats the water moving through the pipes of the heating system.

In order to build a water "jacket", two pieces of sheet metal are taken, bent into rings and connected by means of a welding machine in such a way that a closed metal casing is obtained. The optimal metal thickness is 3 mm. A heating boiler of the Bubafonya furnace is installed inside the casing, then pipes supplying water and air are connected, a cover of a suitable size is made and the finished structure is operated.

To reduce heat loss to the atmosphere, the iron walls of the fuel tank are coated with clay mortar, then brickwork is erected.