For heating small rooms, heaters or expensive stoves are often used. But, having shown a little ingenuity and skill, it is possible in a minimum time to build a long-burning stove from practically waste materials that runs on one of the cheapest types of fuel - sawdust. Furnace "Bubufonya" good for its simplicity. It is easy to install it in a greenhouse, heat a garage, country house or other small rooms with it. It does not require the cost of electricity or gasoline.

Content

sawdust as solid fuel

This environmentally friendly and most economical type of fuel can be of several types. One of them - chips and sawdust in bulk. They are easy to get from woodworking factories where they are waste or if there is a carpentry shop nearby. Briquettes and pellets are made using a special press. This process with the help of simple devices can be adjusted at home.

The next type of fuel is pellets. They are much more profitable than ordinary firewood (they burn longer, and the cost is several times lower). They are very easy to transport and store.Pellets are small capsules (about eight millimeters in diameter) made of compressed sawdust.

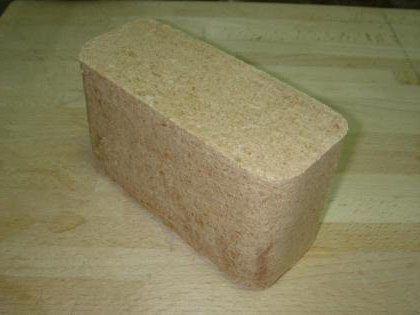

In addition to pellets and loose sawdust, long-burning stoves are used fuel briquettes. They are cylindrical, rectangular, six- and octahedral (Pini-Key).

Video:

Benefits of using sawdust as fuel

- Low cost of fuel;

- Ease of storage;

- Heat transfer and burning time are higher than conventional firewood or peat briquettes;

- Pellets do not emit soot and toxic substances during combustion;

- The products of combustion remaining from the burning of sawdust are a good fertilizer for the garden;

- There is much less garbage from sawdust and pellets than from firewood and coal;

- Due to the fact that the sawdust is always dry, they can light the stove at any convenient time, while firewood sometimes requires additional drying;

- When burning fuel briquettes or sawdust, much less ash and ash is generated than when burning firewood.

Disadvantages of using sawdust

The disadvantages include dust from sawdust, which in rare cases can cause an allergic reaction, as well as the fact that, if stored improperly, sawdust can ignite spontaneously. However, both of these factors are extremely rare.

How to make fuel briquettes for use in a long-burning kiln

To make sawdust briquettes you will need:

- wooden beams, nails and a hammer for assembling the press;

- two metal cylinders - forms for future briquettes;

- sawdust;

- water.

Step-by-step instruction:

- Pour sawdust into a deep container and mix with water until the consistency of thick sour cream.

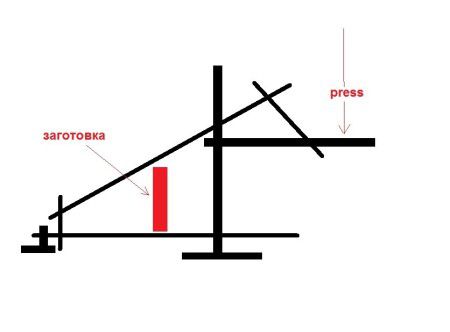

- We assemble a press from wooden beams according to the scheme. The principle lies in the leverage system.

- We put wet sawdust in a metal mold and press it by pressing the handle of the wooden “machine”.

- We take out the finished briquettes from the mold and lay them out to dry.

Another similar way to make fuel briquettes for the stove is to knock together several wooden boxes with many cells, mix sawdust with water and a small amount of clay, hammer this mixture tightly into the cells of the boxes to let the water out. A day later, we get the fuel briquettes and use them for their intended purpose.

Do-it-yourself stove "Bubafonya" on sawdust

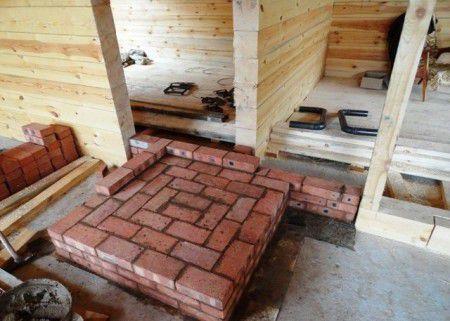

Since the combustion temperatures of sawdust are higher than the combustion temperatures of firewood, the walls of the fuel tank must be made thicker - at least 10 mm. And to ensure fire safety, the furnace is installed on the foundation and equipped with a reflective screen, a water circuit, or the furnace is lined with refractory bricks.

Furnace mounting material:

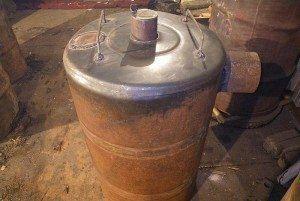

- a thick-walled barrel with a sealed bottom (or a used gas cylinder) for a firebox, it is advisable to choose a volume of about two hundred liters;

- two pieces of metal pipes;

- channel;

- sheet metal;

- grinder, cleaning and cutting wheels for it;

- a hammer;

- welding machine and electrodes;

- hacksaw for metal;

- bricks and cement for the foundation.

Work must be carried out in accordance with safety regulations. In addition, it is necessary to carry out work near the source of electricity.

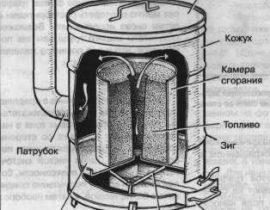

1. Fuel tank

If a barrel or cylinder is used, the top must be cut off. To do this, use a grinder or a hacksaw for metal.According to the markup, cut off the upper part, carefully making sure that the tool does not overheat, and the cut line is even. The remaining part can later be used as a furnace cover.

In the case where the fuel tank is made by welding from sheet metal, it is first bent into a radius on a bending machine, then connected by a welding machine in the form of a cylinder. To this cylinder, a bottom of the appropriate size is cut out of a piece of sheet metal and welded to it, monitoring the quality of the weld.

2. Pressing circle and supply pipe

The diameter of the pressing circle should be slightly smaller than the diameter of the fuel tank. This will ensure its free movement in the furnace as the fuel burns. In the center of the pressure circle, it is necessary to cut a hole equal to the diameter of the supply pipe. After that, the channel is sawn into 4 equal sections and welded to the circle. This is necessary to increase the mass of the pressure wheel and provide additional structural strength.

The length of the supply pipe is calculated as follows: measure the length of the fuel tank and add from 20 to 50 cm to this value.

The supply pipe and the pressure circle are connected by welding.

It is necessary to make a damper on the pipe, with the help of which the amount of air entering the furnace will be regulated. The simplest damper is a small metal circle with a steel bar handle for ease of use.

3. Outlet pipeline

To attach it to the firebox, markings are made on the top of the tank and a hole is cut out equal to the diameter of the outlet pipe. After that, the pipe is attached by welding.The pipe is connected to the main heating system by means of a clamp and heat-insulating material (fiberglass).

4. Lid

The lid is cut from a piece of metal sheet or a cut-off part of the barrel is used for this. A hole is cut in the center for the supply pipe and handles are welded from bent metal rods.

To protect the stove from overheating and improve heat distribution, a sheet of metal - a reflector - is welded to the outside of the fuel tank (with small metal corners).

The foundation is laid out from two rows of refractory bricks.

How to properly drown "Bubafonya" with sawdust

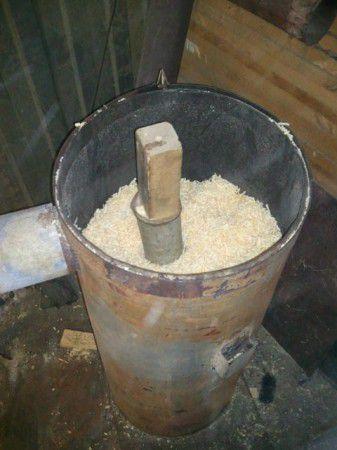

Before putting sawdust into Bubafnya, a pipe of small diameter is placed inside the combustion chamber. Sawdust is laid around this pipe, compacting them tightly.

When the sawdust is laid to the very top, the pipe is pulled out. Thus, sawdust is stacked in the furnace in such a way that the resulting combustion products will be blown down by the air flow (draft) into the shaft formed by the pipe.

The sawdust is ignited with a torch or matches, closed with a pressure disk, a lid, and the furnace is watched for several minutes, adjusting the valve gap and, accordingly, the draft and combustion intensity.

Thus, from the cheapest materials, a long-burning furnace using biologically pure fuel with an efficiency of almost 100% is obtained. The Bubafonya stove on sawdust is the best option for economical owners.

Bubafonya in one day - video