Very often there is a need to purchase a stove that runs on sawdust and small chips. This is especially true for those who have at their disposal a carpentry workshop or a woodworking enterprise in the immediate vicinity.

sawdust stove

Sawdust is environmentally friendly, burns well, is cheap, has a high temperature and burning time. They are used as fuel in bulk or pressed into briquettes and pellets. Sawdust stoves are good for heating greenhouses, garages, utility rooms, workshops and other similar premises. They are easy to make with your own hands from brick, metal, or by combining these materials. The simplest models are assembled from steel barrels, scraps of thick-walled pipes, or from spent gas cylinders.

Content

Sawdust stove construction

A sawdust stove without an external circuit consists of a fuel compartment, under which there is a second bottom, an opening with a door for loading firewood and a blower for oxygen to enter the stove. Also, the sawdust stove is equipped with a lid and a chimney. A metal valve is placed on the chimney to reduce heat loss.

How to fire up the stove

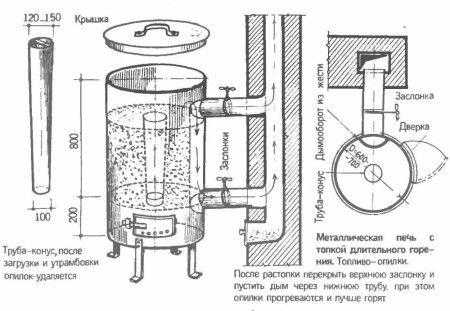

We prepare fuel - sawdust, chips and medium-sized firewood. We load sawdust into the upper part of the firebox for 2/3 of the volume of the firebox.To do this, we insert a cone-shaped pipe, tightly press the sawdust around it. Firewood is placed in the lower part of the furnace through the blower. We remove the cone-shaped pipe, close the stove with a lid, open the damper on the chimney. We burn wood. The heat from burning wood causes the sawdust to smolder.

The principle of operation of the furnace

- Option 1

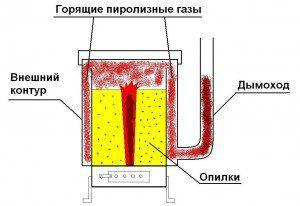

The hot furnace gases released during the combustion of fuel rise up through the channel in compressed sawdust and enter the chimney.

- Option 2

During the smoldering process, sawdust emits heat, which, in turn, rises to the furnace lid and enters the external contour of the furnace through the "board". Here, hot furnace gases cool down and are disposed of in the chimney.

We build a stove on sawdust with our own hands from a thick-walled pipe

For the fuel tank, we use a piece of thick-walled metal pipe. The optimal diameter is 40 cm. For a chimney, you need a pipe with a diameter of 10 cm. In addition, it is necessary to prepare black tin or sheet steel with a thickness of at least 5 mm.

Procedure

- Let's start making the fuel tank. To do this, cut a hole with a diameter of 10 cm in the upper part of the existing pipe.

- Next, prepare the bottom of the oven. Cut out a circle from sheet metal. The diameter of the circle and the pipe - the firebox, respectively, are equal. To make a cut, we make a markup. We put the pipe on a sheet and circle it with a marker or a can of paint, after which we cut a circle along the contour with a grinder. In the center of this circle, it is necessary to make a hole (diameter 5-8 cm).

- We make a pipe that provides oxygen access to the combustion zone. We take a pipe segment equal to or longer than the fuel tank. The diameter of the pipe should be equal to the diameter of the hole in the firebox (5-8 cm).Using a grinder, we cut several longitudinal lines in the pipe, or use a drill to make a perforation (at least 50 holes, diameter 0.8-1 mm).

- We insert the perforated pipe into the hole in the bottom of the furnace and weld it. We make a cover. From sheet steel we cut out a cover of a round or polygonal shape. In the center we make a hole equal to the diameter of the perforated pipe (the lid should fit tightly on the pipe with slots) and another hole closer to the edge. It is necessary for the access of oxygen to the furnace and draft control.

- You will definitely need a shutter. As it, you can use an ordinary metal lid from a can or cut a circle out of steel, weld a bolt vertically to the hole located at the edge of the lid, drill a hole in the flap, put it on the bolt and tighten it with a nut. Thus, an axis-shifted damper-blower will be obtained. For convenience, the lid can be equipped with two handles in the form of brackets made of metal rods.

- We install a chimney for the exit of flue gases from the combustion zone. To do this, we use a pipe with a diameter of 10 cm and the corresponding pipe, which we will connect to the pipe, connecting them with a clamp. The branch pipe is hermetically welded to the hole on the upper side of the furnace.

- We connect the chimney, putting it on a couple. We seal the connection with heat-insulating material. From above we tighten with a wire or a strip of metal with holes for bolts.

- The oven must be placed on a support. For support, metal profiles are required.We cut out 3-4 sections of a metal profile equal in length and weld them to the furnace body on sawdust.

All metal parts of the oven get very hot. It is not recommended to install the oven near flammable liquids, materials and surfaces, as well as to touch hot metal without protective gloves. Do not leave the oven unattended. By following these few simple safety rules, you will protect your property from fire, and the stove will work efficiently, heating the room.

Sawdust stove without external circuit

The advantage of the design is that it does not require the use of a cone pipe for laying fuel and the convenience of cleaning the furnace from combustion products.

To make such a stove on sawdust, you will need a barrel / pipe / piece of a gas cylinder with a wall thickness of 5 mm. Also useful: grinder with cutting and cleaning wheels / hacksaw / chisel and hammer; welding machine; Sheet steel; metal fittings; hairpins; chimney pipes.

1. Making a fuel tank

To do this, prepare a metal barrel or pipe. If a balloon is used, then it is necessary to cut off the top from it, from which we will later make a cover. The optimal volume is 200 liters. We use a pipe segment with a wall thickness of 10 mm and an inner diameter of 40 cm. In the upper part of the fuel tank, we cut a hole with a diameter of 10 cm for the subsequent installation of a pipe attached to the chimney. In the lower part, we drill a hole with a diameter of 5 cm. Here we attach a pipe of the appropriate size with a perforation pre-drilled in it (about fifty holes of 8-10 mm each). We seal the top of the perforated pipe hermetically.

2. We weld the pipe to the side wall of the fuel tank. It will serve as a chimney.

3. Lid on the stove

We cut out the lid from a thick sheet of metal and reinforce it with reinforcement / corners along the edges. We weld a handle on top for ease of use. If we mount the stove from a cylinder, then we fit the remaining upper part under the cover, similarly strengthening its edges.

So that the stove can be conveniently cleaned of ashes, we weld two studs to the outer sides of the stove and assemble a support structure from metal corners (two corners-racks and a square-shaped base). Thus, to clean the oven, it will be enough to turn it over.

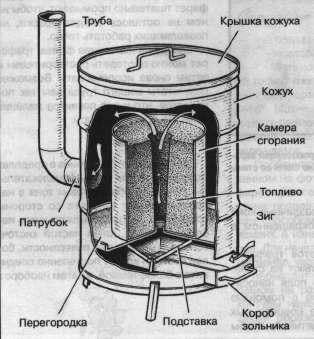

Sawdust stove from two barrels

The furnace consists of two main parts: in the first, combustion takes place; the second is a heat exchanger.

- We prepare two metal barrels in advance. The thicker the walls, the more durable the structure will be. We take the first barrel with a volume of two hundred liters, the second - fifty liters. You can use casings from square-section washing machines.

- Cut off the top of the casing. From the smaller part we make a lid, reinforcing its edges with fittings or corners. Weld the handle-bracket to the lid.

- From three corners (length 10-12 cm) we make legs. Length 10-12 cm.

- We cut out a sheet of metal with a grinder, which we install as a partition-support for mounting the chamber in which the fuel combustion process will take place. We drill a hole with a diameter of 6 cm in the center of the partition.

- We insert a smaller tank with a drilled hole (6 cm) inside the structure. The hole in the bottom and the hole in the baffle must match.

- We lay the partition on a support in the shape of a triangle (stand) from steel rods welded together. The height of the support is 15 cm. We install the triangular stand itself on the bottom of the outer casing.

- Under the partition we mount a box for collecting combustion products. The box consists of a bottom, side and end walls and a handle-bracket for easy opening and closing of the furnace. We cut a 30x13 cm hole for it in the wall of the outer tank. We weld a steel box (1 mm thick) to the hole.

- We hermetically weld a pipe into the central part of the tank, having previously cut a hole of a suitable size for it. We will connect the chimney pipe to the pipe using a clamp and heat-insulating material.

Next, we lay down the fuel, still using a cone-shaped pipe around which we carefully tamp the sawdust. Then we take out the pipe, set fire to a long match and throw it inside the channel left after removing the pipe.

To protect the metal parts of the furnace on sawdust from corrosion, we cover all parts with heat-resistant paint or a mixture of aluminum chips and liquid glass.

Video - do-it-yourself stove on sawdust