The Slobozhanka oven belongs to the convection type. Slobozhanka is used in agriculture for heating greenhouses and greenhouses, garden houses, garages, workshops and other residential and non-residential premises.

The Slobozhanka oven belongs to the convection type. Slobozhanka is used in agriculture for heating greenhouses and greenhouses, garden houses, garages, workshops and other residential and non-residential premises.

Content

The principle of operation of the furnace and the main structural elements

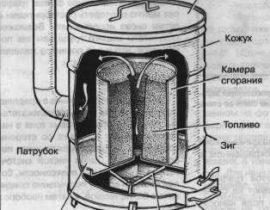

The furnace has two casings, and the outer one is separated from the inner by a system of fasteners and an air gap. Due to this, cold air flows enter the stove from below, where they heat up and rise to the top. So there is a gradual heating of the room.

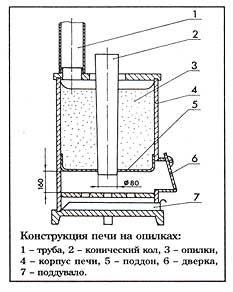

Solid fuel (pine needles, sawdust, firewood, straw in bales, etc.) is placed inside the fuel tank. If logs are used, they are placed vertically. Burning starts at the top and continues down. In this case, the combustion fuel is distributed either with an inclination towards the chimney, or towards the periphery (walls). The oven lid and blower allow you to adjust the intensity. Flue gases are removed through the chimney, and the ashes through the pan from below.

Air supply system options:

- - The first type.The air enters through the L-shaped pipe, then upwards, along the side channel of the perforated screen (the screen is located outside the pipe) and then into the combustion zone.

- - The second type. In these designs, the pipe is located in the center of the firebox. Air enters from bottom to top.

- - The third type. In structures of this type, the air supply pipe is mounted at the very bottom of the furnace wall.

Advantages and disadvantages of the Slobozhanka

The Slobozhanka has a high efficiency - up to 90%, the remaining 10% is lost, going into the chimney. The stove heats up quickly, but also cools down quickly after the fuel stops burning. The design is very simple, the manufacture of the furnace does not require special tools and expensive equipment, it is easy to make it yourself. At the same time, it is reliable, mobile and economical. With a firebox volume of 200 liters, one load of fuel is enough for about 12 hours. In this case, additional reloading is possible with the heating system running.

What is needed for construction?

Prepare the following tools: a drill with a set of drills or a small drilling machine; angle grinder - grinder and a set of discs for grinding and cutting metal; welding machine (can be semi-automatic) and general purpose electrodes; pipes with thick walls; sheets of metal; riveting; a hammer; chisel; fittings and metal corners; two barrels or pieces of gas cylinders; tape measure and heat-resistant paint.

Do-it-yourself Slobozhanka oven with a central air supply

- We select a suitable thick-walled cylinder. For example, a cut of a pipe, a spent gas cylinder or titanium. Diameter - at least 25 cm.

- We cut a circle from sheet steel with a grinder, the diameter of the circle is equal to the diameter of the pipe. In the center of the circle, we drill a hole with a diameter of 8-10 cm. We will connect an air duct to this hole.

- For the air duct, a pipe with a diameter of 8-10 cm is required, the length of the pipe should be slightly less than the length of the combustion chamber, we make markings on the walls of this pipe - several vertical lines. Cut the pipe along these lines (without separating the pipe completely, you should get several vertical cuts).

- We make a blower. To do this, we weld a bolt to the cut pipe at its very bottom with a welding machine. We cut out a circle from steel equal to the diameter of the pipe, make a small hole for the bolt in it, put on a metal circle (previously cut from a sheet of metal, take the diameter equal to the diameter of the pipe, for convenience, weld a small handle or nut on the outer part) onto the bolt and tighten with a nut. Thus, the circle can be shifted along the axis, and the volume of air entering the furnace can be adjusted.

- Next, you need a sheet of steel with a thickness of 0.8 to 1 cm. The thickness is due to the high heating temperature and direct contact of the part with fire. We do markup. The outer diameter of the circle is taken a few centimeters less than the diameter of the fuel tank, the diameter of the inner hole is taken equal to the diameter of the pipe with grooves. We cut it out with a grinder, put it on a pipe with grooves (20-30 cm from the edge) and fix it by welding.

- Installing a chimney. In the upper part of the wall of the firebox we cut a hole with a diameter of 10 cm, weld a pipe section of equal diameter to it.

- We will make a heat-dissipating disk from thick steel (thickness 1 cm). We cut it out a little less than the inner diameter of the furnace and equip it with metal handles for ease of use. Similarly, we make a cover for the body of the furnace.

- We proceed to the installation of the outer casing of the furnace. To do this, either use a piece of pipe, a little larger than the firebox, or cut out the necessary piece of steel and make a cylinder out of it, seal the seam hermetically (steel can be riveted instead of welding).

- We make fasteners on the casing wall to create a constant gap. To do this, we weld metal fittings or profiles of small thickness inside.

- Next, you need to raise the stove above the floor level by 25-30 cm. To do this, we make the base-legs. We cut the metal corners into equal sections (6 pieces), make a support in the form of a triangle, and weld the legs to the corners. We install the oven on a support.

We connect the chimney to the stove pipe with clamps, laying heat-insulating material (for example, mineral or stone wool) at the junction of the pipes. To reduce heat loss through the chimney, it is recommended to insulate it by wrapping the entire pipe with thermal insulation, and putting on another thin-walled pipe on top, on top of which it is necessary to fix another layer of insulation. However, if the stove heats the greenhouse, then such operations are not necessary.

Video - Slobozhanka oven for long burning