Electric heating has always been expensive, so there are many craftsmen who build various modifications of waste oil stoves. It is financially profitable, it allows you to heat a room of any size, quickly and evenly, in addition, mining furnaces are rational in cases where there is no need for round-the-clock heating. If necessary, such a furnace can be easily dismantled and transported to another location or replaced. It is desirable to install them in non-residential premises (garages, workshops, warehouses) with good ventilation (to remove all fumes that are produced as a result of oil combustion).

Content

Preparation for work and installation of the furnace for working out

The combustion temperature of waste oil products is very high. The metal parts of the oven, when heated, can cause a fire. Therefore, care must be taken to protect the premises from the risk of fire. There is no need to build a foundation, however, heat-insulating material (for example, asbestos sheets) and steel sheets should be fixed to the walls and floor in the place where the stove will be located. Or, using bricks, lay out a small platform-base under the stove.

Now that the place for the furnace is ready, prepare for work the welding machine, gas cutter, metal pipes (for the furnace body and a small diameter pipe for the chimney), a loop, fittings (three pieces) and sheet steel.

Waste oil stove assembly step by step

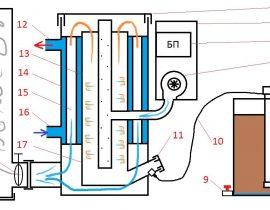

From sheet steel, it is necessary to pre-cut two circles (top and bottom of the furnace) equal to the diameter of the pipe - the future body ovens. Cut holes in the center of the circles. We set aside the circles of small diameter remaining after cutting, they will come in handy in the future. We hermetically weld one of these circles with a hole to the bottom of the furnace. The other circle will serve as the lid of the oven.

Next, on the body we make a hole under the door, through which we will fill in the used oil and connect the pipe to the bottom and top (they are steel circles with holes in the center).

We equip a rectangular piece of steel cut from the pipe wall with a handle made of bent reinforcement and a hinge on which the door will be held. For tightness, the edges of the door are scalded with strips of steel. At the same time, we equip the oven with legs-stands made of reinforcement or corners (we cut out 4 sections of the profile of equal length and weld it to the body of the oven).

Next, we take a pipe of small diameter and make several shallow vertical cuts on it with a grinder.

We attach the resulting part with a welding machine to the bottom of the furnace.

We take out the deferred metal circles left after cutting holes in the bottom and top of the furnace.We weld one of the circles to the bottom.

We make a cover. We take the remaining circle with a hole in the center and weld a short piece of pipe to it (the diameters of the pipe and the inner hole must be equal), to which we will later connect the chimney. We weld the resulting part along the perimeter to the pipe.

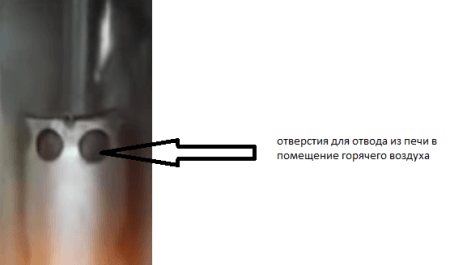

At the top of the furnace body, we drill two holes to remove warm air into the room. We equip the holes with shutters (metal circles that we attach to the body with a nut and bolt).

In order for the stove not to corrode and last longer, we cover it with two or three layers of heat-resistant paint.

How to start the furnace for working out?

First of all, we connect a vertical chimney (we put a metal pipe on the pipe located on the stove lid) at least one meter long. Then we simply pour the used oil onto the bottom of the furnace (into a bowl with holes for air access) and kindle it with a torch. Then close the door tightly. Be sure to remember the safety precautions:

- do not leave the oven unattended;

- do not use flammable liquids for ignition;

- ;do not use the oven to dry clothes and shoes.

The advantage of this design is the possibility of using ordinary solid fuel (firewood or fuel briquettes) instead of used oil.

This design can be modified with a blower fan and a protective screen.

Making a mining oven is very easy if you know how to handle tools and have inexpensive materials. And how nice it will be when your handmade creation will warm you and your family members! It's not a shame to show and brag to your friends!

Do-it-yourself oil refinery furnace, video tutorials on how to create

The first option with a more intricate design.

The second option with a simple design, for which even drawings are not needed: