Heating of utility rooms, service stations, greenhouses and workshops is an urgent problem for many.

Boiler in operation

It is not always possible to gasify these premises, and it is very inefficient to use heating with electrical appliances. A mining boiler with a water circuit is an excellent solution that allows you to use resources economically and efficiently.

In this article, we will consider the principle of operation, the design of the boiler for testing, and tell you how to build this unit with your own hands.

The main advantage of such a boiler is fuel efficiency, because sometimes you can even get it for free. Many car services and workshops give processed oil with the condition of self-delivery.

Content

Principle of operation

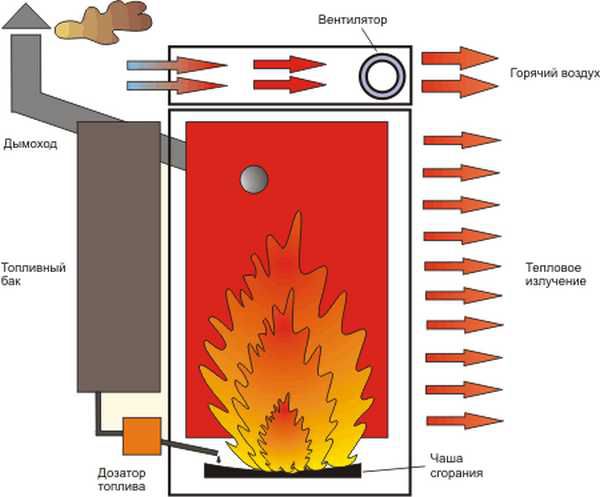

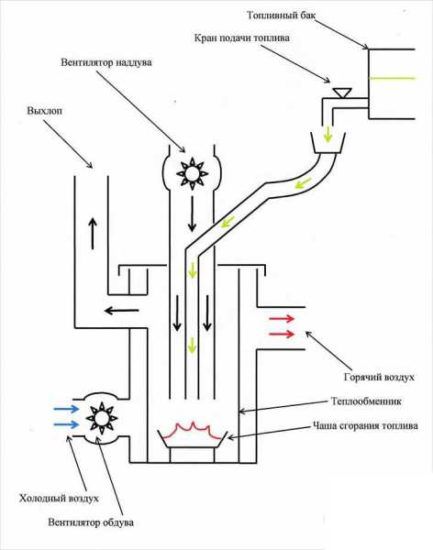

The principle of boilers operating on recycled fuel is the same in all cases. It consists in evaporating the oil and burning the steam from it.

Principle of oil evaporation

But there are small nuances in such technology. All used oils contain many heavy metals, additives and other elements. The task is to build such a unit that will allow to accumulate heat inside, and not to remove all these elements at once into the chimney. Complete oxidation of all elements occurs only if the maximum temperature inside the boiler is reached - 6000FROM.

The temperature indicator in this case is a very important point. Without going into long explanations of chemical processes, we can say briefly: harmless combustion and evaporation of fuel can only occur at a temperature of 600 degrees. Deviation to one side or the other by 200 degrees will provoke the release of very harmful toxic substances.

Waste boiler with water circuit

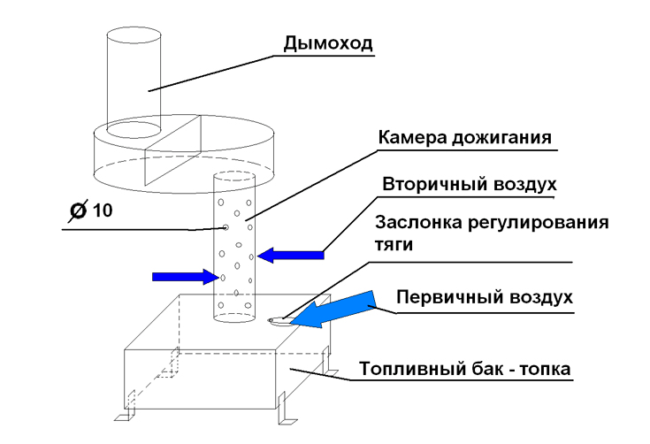

A home-made boiler for mining looks like this: two metal containers are interconnected by a pipe and at the same time they are at different heights. The upper tank is equipped with a flue pipe, the length of which must be at least one meter.

Waste oil is poured into the lower tank. The top layer of oil in the evaporation chamber is heated, resulting in the formation of steam. Rising, it goes into a perforated pipe and connects with air, reaches the upper tank and burns out. And already the combustion products themselves are removed through the pipe through the chimney.

Thus, the room is heated, but no toxic waste harmful to human health is released. This fact immediately answers the main question that interests many before the construction of such a unit: “How harmful is the mining boiler?”.

Scheme of a waste oil boiler

With the correct design and observance of all necessary technical points, a spent fuel boiler does not pose a threat to human health. But here you need to strictly adhere to the operating conditions and understand that this unit is suitable for heating only utility rooms. It is impossible to perform such a device for heating a house. After all, it uses spent fuel, which is difficult to attribute to clean fuels.

You should clearly understand the principle of operation and the technology of oil evaporation in such a unit. It is not the oil itself that burns here, but its vapors. Due to the fact that the spent fuel heats up and begins to evaporate even before the start of combustion, it becomes possible to decompose such burning fuel into lighter elements.

Where are these heaters used?

- in industrial premises;

- in premises for keeping animals;

- in auto repair shops, at service stations;

- in greenhouses;

- in warehouses and garages.

Almost any oil can be used as fuel for such a boiler, including depreciation oil.

The technology of oil evaporation in the boiler during mining

Combustion of fuel and evaporation of oil can occur in two ways:

- Ignition of a liquid substance. In this case, steam will be released, which will burn out in a special chamber.

- Pouring a liquid onto a hot surface, resulting in the formation of steam.

One of the easiest ways to implement this technology is to use a hot metal bowl, on the surface of which used oil drips.

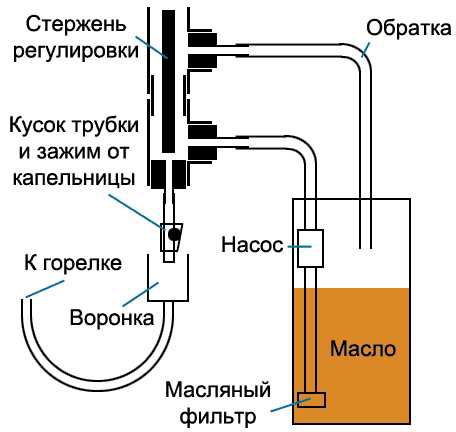

The principle of drip fuel supply

The bottom line is that when in contact with hot metal, the fuel evaporates abruptly, and does not heat up.There is a diffusion of steam with air, which is supplied to the tank. Vapors ignite and burn, resulting in heat.

In order to achieve maximum efficiency of such a unit, it is necessary to ensure that the burning mixture remains in the combustion chamber for a long time. To do this, install a fixed impeller at the mouth of the chimney, which will help create the necessary turbulence in the combustion chamber.

A homemade boiler without a water circuit can heat a fairly large area. Its power is enough to heat a small workshop of 30-40 square meters, a greenhouse or a garage.

If it is necessary to provide heating of large rooms, then a boiler with a water circuit should be made. At the same time, fuel consumption is striking in its efficiency: from 0.5 liters to 1 liter per hour.

Depending on the needs and desires of the owners of utility rooms, such a home-made unit can be equipped with one or two circuits. If the task is reduced solely to heating the room, then one circuit will be enough.

If it is necessary to heat water for domestic purposes, then two circuits must be completed. For these purposes, a heat exchanger is installed in the upper tank.

Despite the excellent efficiency, versatility of fuel use and great efficiency, this principle of operation is rarely implemented on foreign boilers. But domestic manufacturers often produce such units, which are widely used for economic purposes.

The most difficult thing in the independent implementation of such a design is the method of preheating the bowl onto which oil is dripping.Those who make such a boiler with their own hands act simply: they throw a wick soaked in gasoline into the tank and set it on fire. After the bowl is heated to the desired temperature, simply open the oil supply.

Boiler in operation

The second point that you need to pay attention to is a uniform drip oil supply. It is necessary to ensure the optimal level of spent fuel filtration.

To do this, it is enough to put an automobile oil filter on one end of the tube, which is lowered into the spent fuel tank. The filter must be changed at least once a month. If the fuel is dirty, then more often.

Another problem may be the fuel pump, which must supply the right amount of oil to the tank. Having assembled a structure of fittings, a nipple and two tees, you can milk "protection" from fuel overflow. The hose will contain a portion of the oil that is placed in this assembly.

Pump

The rest will simply drain back into the tank. According to a similar scheme, the factory design of the boiler with automatic overflow protection is also carried out.

Another idea for dripping fuel is to use a fragment of a conventional medical dropper. This fragment is put on the lower fitting, and the drop frequency is determined using the control wheel.

The amount of fuel that drips onto the bowl should be just enough so that it burns evenly, but does not smoke. If the fuel is changed, it is necessary to re-adjust the drop frequency each time.

A good modern mining boiler must be equipped with protection against oil boiling and fuel overflow.To avoid a fire, you need to ensure that the oil level in the tank is lower than in the stove itself.

In order to make a boiler with a water circuit, it is enough to arrange a water jacket around the furnace body. Further, this circuit can be used at your own discretion: either to supply for heating a large room, or for heating water.

In order to connect the pipes leading to the heating system to the tank, you will need a pump to circulate water.

The mining boiler seems to be good for everyone: it is both economical and easy to operate. But how to ensure that it maintains combustion for a long time?

Way to prolong burning

It is impossible to add oil during its operation - it is dangerous. Waiting for complete combustion is inconvenient. You can, of course, make a large fuel tank, but then a large amount of oil will not have time to heat up to the desired temperature.

An additional tank will help to solve this problem, where the main fuel supply will be poured. It will be connected to the lower body according to the principle of communicating vessels.

Advantages and disadvantages of a mining boiler

Like any heating unit, a mining boiler has its advantages and disadvantages. Before you decide to do it yourself, we suggest that you familiarize yourself with this list in detail.

Advantages:

- low cost of resources;

- simple design and clear principle of operation of the boiler;

- the ability to use the boiler to heat water (during the construction of a water circuit);

- rapid heating of the liquid;

- the possibility of making your own hands;

- compactness;

- high efficiency.

The relative environmental safety of such a boiler can be attributed rather to advantages, but it should be emphasized that this safety is achieved only with strict observance of all technical nuances during construction and operation.

DIY boiler

The “outlet” boiler produces a temperature of 95 degrees, which makes it possible to heat the garage, greenhouse, workshop well even in the most severe frost.

It is possible to provide a small hob on the design, with which it will be easy to heat the kettle or warm up dinner.

Flaws:

- the need for regular cleaning;

- lack of support for this unit at the legislative level;

- unrepresentable appearance.

As you can see, the advantages of such a design for heating are much greater than the disadvantages. Therefore, if you decide to build a mining boiler with a water circuit on your own, we offer you step-by-step instructions that even a beginner can handle.

Fire safety measures

It should be understood that such a home-made design must be made clearly in accordance with established fire safety standards.

To protect the premises from fire, we also recommend that you adhere to the following rules:

- The chimney diameter must be at least 100 mm. Ideally, use sandwich pipes, on the surface of which a minimum amount of soot is formed.

- In the immediate vicinity of the tanks, it is forbidden to store flammable objects (fuel tanks).

- All joints must be sealed.

- The thickness of the walls of the tanks where the combustion of fuel takes place must be at least 4 mm.

- To ensure the flow of fresh air into the room and to avoid smoke, it is necessary to equip the boiler room with a forced circulation system. The rate of air exchange per 1 cubic meter of area is 180 m3/ hour.

How to make a mining boiler with a water circuit with your own hands

In order to independently perform this unit, you need to stock up on the following materials:

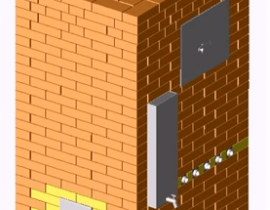

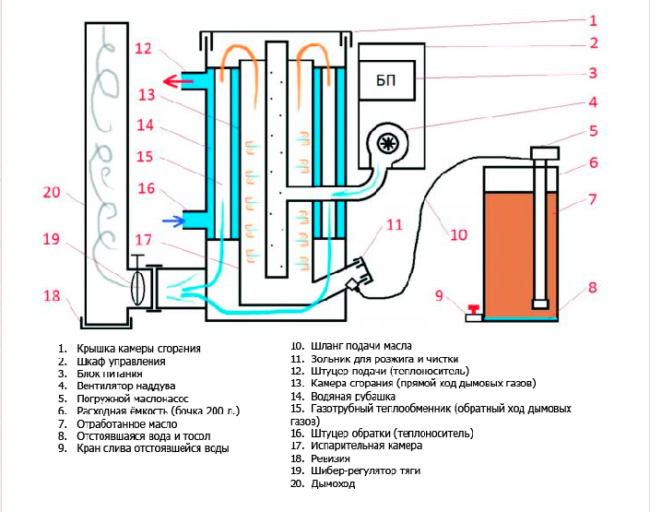

Diagram of a mining boiler with a water circuit

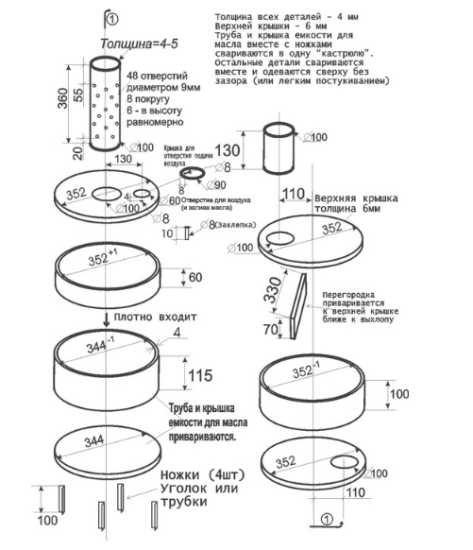

- sheet metal for the tank (thickness 4 mm);

- sheet metal for the cover (thickness 6 mm);

- chimney pipe;

- oil pump;

- fan;

- steel adapters;

- heat resistant sealant;

- metal corners for supports.

Tools:

- grinder with a circle for cutting metal;

- pencil and construction tape measure;

- drill with a drill for metal;

- hammer and a set of keys;

- electrode welding.

To facilitate the work on the implementation of the boiler, you can take ready-made barrels for propane or oxygen.

Boiler working out scheme

The assembly diagram of the unit will look like this:

- The boiler body must be divided into 2 parts. In the upper part, you will need to mount a water jacket, and connect the lower part to heating radiators. The lower part must necessarily be separated from the upper part, to which the pressure pipe is connected.

Making a partition

- We pass the pipe through the partition between the upper and lower parts. Be sure to ensure that the inside of the pipe is well insulated from water, otherwise water entering the oil may cause a fire.

perforated pipe

- The cover of the primary chamber is welded onto the perforated end of the pipe, while the cylinder must be freely removed from the cover.

- A fitting cuts into the bottom of the tank through which air and oil pass. In this case, the fitting passes through the housing and is connected to the nozzles of the burner using hoses.

- In the boiler body itself, in its lower part, it is necessary to provide a door for the systematic cleaning of soot.

Before performing work, it is necessary to determine the place where the boiler will be placed. It is necessary to make sure that there are no flammable things nearby and the boiler body itself does not block the movement, does not interfere with work.

Numerical parameters of the boiler

Step 1. Preparing the base and walls

- Under the mining boiler with a water circuit, it is best to make a concrete screed. It is also possible to tile the floor and the wall adjacent to the boiler structure.

Walls must be of non-combustible material

If the walls are wooden, then an asbestos sheet must be laid between them and the unit.

Step 2. Making the main tank of the boiler (internal)

This body is a tank with a water jacket, an oxygen supply channel and a tube through which oil flows to the bowl.

At the bottom of this case, it is necessary to make a door to remove the bowl and ignite the oil.

- Draw a diagram of the boiler.

- Measure the dimensions of the tank on sheet metal and cut it out with a grinder.

- Cut out the bottom of the tank.

- We connect a sheet of metal in such a way that a pipe with a diameter of 60 cm is obtained.

- We attach the bottom.

Weld the base securely

- In the bottom we measure the hole for removing the bowl. The size of such a hole can be any, as long as the hand fits.

- At a distance of 10-15 cm from the upper edge of the pipe, we cut out a round hole with a diameter of 14 cm.

- Using arc welding, we weld to the openings of the neck with a thickness of 5 cm.

We weld the ring

- We weld a ring 3 cm wide on the lower part of the pipe. In this case, the ring must be “put on” the end of the pipe so that the planes of the two parts intersect at an angle of 900.

Door

Step 3. Making the outer casing of the pipe

- The length of the outer pipe must be 5 mm less than the height of the outer pipe.

- Using a grinder, we cut a hole in the pipe for the chimney, doors, supply pipes (at the top of the pipe) and a hole for the return of the coolant (at the bottom).

- We put the outer part of the pipe on the inner one and hermetically weld the bases.

Bowl with welded bottom

- At the top of the pipe, we weld a ring that closes the distance between the pipes.

- We carry out a plug of one of the pipes.

Stub

- Check the tightness of the water circuit.

Installation of a water bath

- We measure circles of diameters of 66 cm on sheet metal. We cut them out using a grinder. In one circle, we make a hole for the air supply pipe. Diameter - 13 cm.

- We weld the circle to the structure made.

Boiler installation

Step 4. Making an air supply channel

- Measure a pipe with a diameter of 6-8 cm on sheet metal and cut it out with a grinder. The length of the pipe exceeds the overall design by 10-15 cm.

- We measure from one end 50 cm and make a hole.

- Now we are making a channel for the oil supply, which will be inside the air supply pipe. To do this, take a piece of tube 8 cm long (d = 1 cm) and weld to the other end of a tube of the same diameter, but 50 cm long at an angle of 130-1500.

- Carefully install the oil supply tube into the air supply pipe.

- On the side we carry out a tie-in for the compressor. We connect the fuel supply pump and the circulation pump.

- We place the bowl in the cauldron.

- We fix the door.

Step 5 Installing the chimney

After the boiler itself is securely installed on the base, we proceed to the installation of the chimney, the length of which should be 3.5-4 m.

Assembling a chimney from sandwich pipes

At the same time, try to make a vertical pipe without horizontal sections.

- We connect the outlet pipe of the boiler with the chimney pipe.

- Depending on which chimney outlet scheme: through a wall or roof, we perform markings. If we pass a pipe through the wall through the ceiling.

We carry the chimney through the wall

- In the place where the pipe will pass through the ceiling, it is necessary to lay asbestos fiber around the chimney and attach a special heat-resistant casing to the ceiling.

External fastening of the flue pipe

- To adjust the draft, we equip the chimney with a metal damper.

- We remove the chimney above the roof.

Chimney outlet above the roof

Step 6. Connecting the water circuit

If the boiler is to be used as a connection to radiators for heating a large room, the entire battery network must first be laid through the room.

Battery connection

To connect the boiler to the radiator, we use a pipe with a diameter of 43 mm.

- We take a small metal container (water tank) with thick walls, and securely fix it with bolts to the boiler. You can use welding as a fastener.

Connecting the boiler to the system

- We make a hole in the upper part of the tank and weld a pipe through which hot water will be supplied to the system.

Pipeline installation

- In the lower part there is a pipe for the entry of cold (cooled) water into the tank.

Video. Do-it-yourself boiler for working out

Conclusion: a mining boiler with a water circuit is an economical alternative for heating utility rooms, which, if properly assembled, will allow you to heat a room of 30-40 square meters even in the most severe frosts.

We suggest that you familiarize yourself with a detailed video, which shows the operation of the furnace in mining with a water circuit.

Video. How does a mining boiler work