What is a solid fuel boiler? In fact, this is a somewhat modernized stove, which is known to everyone and everyone who has ever visited an ordinary village. Creating a boiler of this type in autonomous home heating systems is the simplest and most logical move. The construction of heating systems, for example, based on electricity or gas, requires at least the organization of the supply of energy carriers. To do this, you will have to enter into negotiations with officials, and they may not always end successfully. But if you build a solid fuel boiler with your own hands, then you can easily get by with independent procurement of energy sources, for example, purchase a pair of firewood or coal. In addition, modern solid fuel boilers can be "omnivorous" and operate on many types of fuel.

Content

Types of solid fuel boilers

The whole variety of designs of solid fuel boilers can be divided into types depending on what fuel they run on:

- Wood boilers: This is a classic option for solid fuel heating.In addition to traditional Russian stoves, a large number of wood-burning boilers with a wide variety of characteristics are now on sale. There are even boilers that also generate electricity. Some of these boiler modifications can be made independently.

- Coal-fired boilers: the high combustion temperature of coal implies higher quality requirements for the manufacture of such a device. The steel or brick used for the construction of such boilers must have a very high fire resistance.

- Boilers on pellets: Such devices appeared relatively recently, but have already managed to win the love of consumers. This is primarily due to the cheapness of fuel. After all, shrouds are pressed granules made from forest waste. In addition, the small size of the pellets and their stable shape make it possible to organize automatic fuel supply to the boiler, which saves its owner from the need to constantly monitor the combustion process.

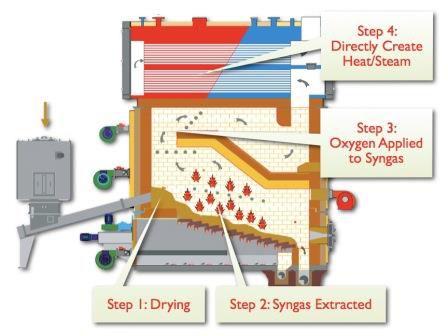

The principle of the solid fuel boiler

In any solid fuel boiler, regardless of the fuel used, there are several main components:

First of all, this is a combustion chamber - a place where fuel burns, which is placed there manually or mechanically. An ash pan is located under the combustion chamber - a place where solid residues of combustion products are collected.

During the combustion of fuel, extremely hot air is created, which naturally rises. On its way there are grate bars, inside of which there can be tubes with the heat carrier of the heating system. During the passage of the coolant through the grate, heat is transferred to the coolant, which is usually water.

After passing through the grate, hot air goes into the chimney and is discharged outside the room.

Building a simple solid fuel boiler with your own hands

That's all the basic elements of which actually consists of an ordinary stove. Its construction will not cause you any special difficulties: just take a suitable metal box or a barrel with thick walls, cut a door for fuel supply in it and provide this device with a chimney - and an elementary potbelly stove is ready. During the construction of a potbelly stove, it is necessary to pay attention to the high-quality insulation of its surfaces from flammable materials, since the iron of such boilers can glow almost red-hot.

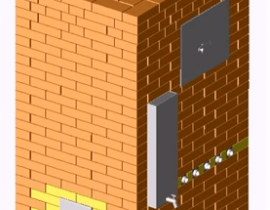

More difficult is the construction of a brick oven. Before its creation, it is mandatory to create a furnace project. In addition, the large weight of a brick oven requires the creation of a solid foundation. Therefore, such furnaces should be designed and built at the stage of building a house. Creating a brick Russian stove is almost an art, and here it is unlikely that you will be able to do the installation yourself. Therefore, the installation of such a furnace, or at least the development of its project, is best entrusted to a specialist. Otherwise, a furnace not built according to a proper design may not have sufficient draft or smoke, poisoning the surrounding area.

Adding a hot water system

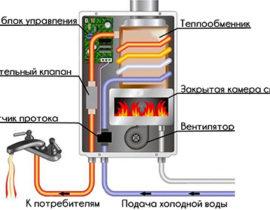

More complex are solid fuel boilers combined with water heating systems. In this case, in addition to increased requirements for manufacturing materials, a competent engineering calculation is also necessary.

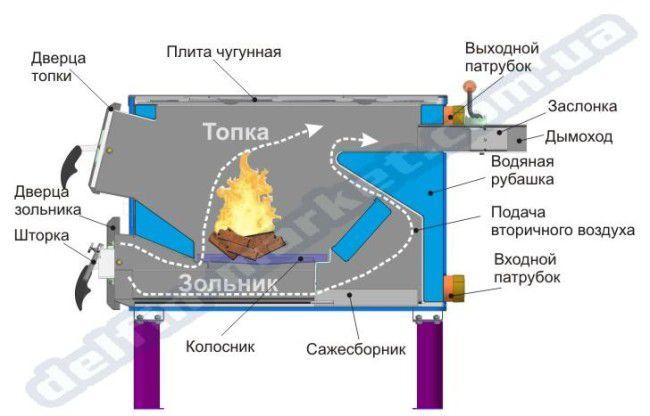

A schematic diagram of a solid fuel boiler with a water heating system is shown in the figure.

In order to build such a boiler, it is necessary to observe several basic fundamental points.

First of all, such a solid fuel boiler must have a rigid and durable structure. Here it will not be possible to do with a simple metal barrel as in an elementary stove-potbelly stove. It will be necessary to create a combustion chamber in such a boiler from a durable metal sheet with a wall thickness of at least a centimeter. It is necessary to connect the cut blanks for the boiler by welding.

To create a home boiler, the area of \u200b\u200bthe bottom should be in the region of one and a half square meters.

Increased requirements are also placed on the heat exchange unit. It is made of steel tubes with a wall thickness of 3-4 millimeters. Please note that in a good heat exchanger, the diameter of the tube decreases as the coolant heats up, so you will not only have to insert pipe sections into the boiler, but purchase specially made parts.

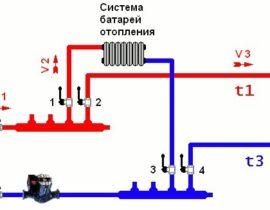

An important issue is the organization of the circulation of the coolant. It can be natural or forced. In the second case, you can place a solid fuel heating boiler in any part of your house, for example, in the basement, and heated water will be delivered using circulation pumps to heating radiators located throughout the dwelling. Also, such heating systems can have several circuits, as a result of which each circuit can be equipped with its own individual pump.

In order to control the operation of such a heating system, it is necessary to integrate control devices into it. You will need two temperature sensors: one will be installed at the entrance to the heat exchange zone, and the second is installed at the exit.Pumps that circulate the coolant can also have step-by-step power control.

Coolant circulation systems in systems with solid fuel boilers can be open and closed. In the second case, the liquid circulating in the system will circulate in a vicious circle, and therefore be used for only one purpose - the transfer of heat to habitable premises. But when creating systems with an open circuit, heated water from the water supply system can be used not only for heating, but also for domestic purposes, for example, for washing.

Creation of a horizontal solid fuel boiler from prefabricated elements

In order to create a simple solid fuel boiler for a heating system, you can also use ready-made elements. The figure below shows such a boiler made on the basis of a metal barrel. At the initial stage, one of the lids is cut off from the barrel. Inside the barrel in front of it is a combustion chamber formed from thick metal sheets. Hot air after fuel combustion enters the heat exchange section located at the rear of the barrel and is then discharged outside through the chimney system. In order to build such a boiler, it is necessary to have welding skills; in another way, all the components of the boiler cannot be connected.

You can install such a boiler indoors on a brick base or on metal supports.

Ensuring continuous power supply to the boiler

The boiler created in this way can be improved by adding to it a continuous feed system operating on pellets. It is a container - a bunker into which pellets are poured from above.In the lower part, a screw device is mounted, familiar to us from conventional meat grinders, which is electrically powered with step-by-step power adjustment. Rotating, the auger moves the pellets into the combustion chamber, while the auger rotation speed regulates the intensity of fuel combustion, and hence the heating temperature.

Maintenance of solid fuel boilers

In solid fuel, as a rule, there is a large amount of non-combustible substances, waste rock, which, after the combustion of organic matter, will clog both the combustion chamber and the chimney. At least twice a week, such a boiler must be cleaned of solid combustion products remaining in it, and at the end of the heating season, you will have to carry out routine maintenance: disassemble the main parts and mechanisms of the boiler, inspect them for damage and clean them from ash and soot.

Video: Making a solid fuel boiler (similar to Stropuva MDA)