In recent years, autonomous heating has become increasingly popular., and not only in private properties, but even in apartment buildings.

This is explained by significant cost savings and ease of use of such a system, as well as the possibility of independent decision-making on the beginning and end of the "local heating season", depending on specific weather conditions. In the conditions of apartments are established certain types of boilers operating mainly on gas, and sometimes — from electricity.

But in the private sector, especially located outside the city, combined heating boilers are well suited, which can work both on wood and on electricity, since it is easy to find solid wood fuel and electricity are almost always in abundance, unlike gas. Especially if, for some reason, the electricity is turned off or served unstable, you can always switch to heating with wood or coalwhich is extremely convenient. blank solid fuel must be carried out in advance in order to always be ready for any prevailing circumstances.

The design of this heater is thoroughly thought out and works equally efficiently both on electricity and on wood.

Content

Features of the design and operation of the boiler

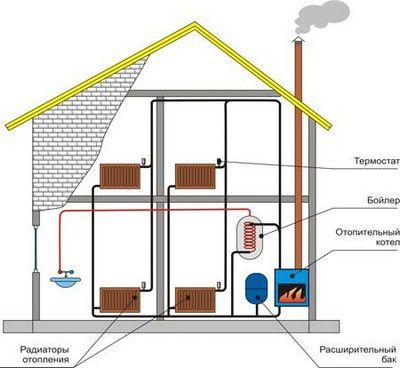

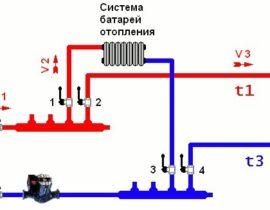

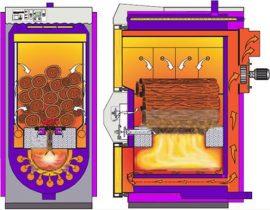

According to its structure combined boilers different from those that work only on solid fuel. Their main feature — presence installed directly in the tank with the heat carrier heating element.

In the lower part of the device there is a firebox in which firewood is burned. The released thermal energy heats the coolant, which is then sent to the heating circuit.

The boilers are equipped with devices that automatically turn on the heating element to achieve the set coolant temperature, if notgets combustion power solid fuel. That eat, when the firewood burns out, the heat subsides, the temperature drops, at this time the heater turns on, and boiler starts to run on electricity. Whole processss proccurs independently, is regulated by automation, and human participation in German not required.

When burning solid fuel is allocated power equal to 26—33 kW, which should be enough for heating houses with an area of 100 — 110 square meters, and then the electric heating element maintains the even required temperature.

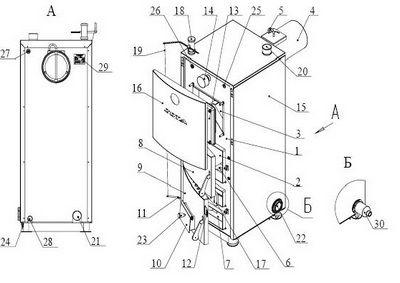

Boiler structure

Boilerworking on solid fuel and electricity, consists of next main nodes and elements:

- Case-box apparatus

- Firebox.

- Gas outlet.

- Chimney pipe.

- damper.

- Grid-iron lattice.

- Ash blower.

- Furnace door.

- Blower door.

- Air door.

- Lever arm.

- gate lock.

- Reflector.

- Pressure gauge.

- casing — frame.

- Front cover.

- Shuttle door.

- Traction regulator.

- Chain.

- Supply pipe.

- Pipe return lines.

- Stub.

- Regulator.

- Ground bolt.

- Sleeve for heat limiter.

- Sleeve for temperature sensor.

- Sleeve for control sensor.

- Drain pipe.

- Wildik with name and serial number of the boiler.

- TEN.

Provided in the design of combined boilers and maintaining a minimum temperature in the circuit in cases where firewood is loaded into the furnace irregularly. it gives the ability to protect the heating system from freezing. That's why, you can leave home for a long time without worrying that the pipes freeze.

It is important that the device can operate at low power, only to maintain the minimum temperature in the system.

Boiler characteristics

To choose the option that is most suitable for your home, in which it is installed, you should consider all its parameters. They are listed in the manual and her You should definitely look before buying the device. These include the following items:

- Boiler power during operation electricity, wood or other solid fuel.

- Availability of the function ensure points drawdown heated water (water heating circuit).

- heat exchanger material. A heat exchanger made of cast iron is resistant to corrosion damage, but its main drawback is that it does not tolerate temperature extremes. Such frequent exposure can lead to cracking of the part.

- If the heat exchanger is steel, then corrosion maybe it is easy to damage, but for that it tolerates temperature changes more easily.

- Must check presence valve, which makes the operation of the boiler safe from the possibility of overheating.

- It is important to consider the size of the fuel chamber — this will depend on how often have to put wood in it.

- The grate installed in the furnace can be made of steel or cast iron, as well as ceramics.

Cast iron grates withstand high temperatures and are suitable for any type of solid fuel. More one advantage of cast iron is that it retains the heat obtained from coals for a long time.

Today, steel and ceramic grates are used more. Due to the shape of the holes in the ceramic grate, they are well suited for the use of fuel in the form of pellets, chips, sawdust and other combustible materials with a fine fraction. But the disadvantage of honeycomb holes is the need for more air to enter, those. you need to make sure that the blower is open in the right way, otherwise the fire may simply go out.

- Important parameters — boiler dimensions and weight. The possibility of its installation in a home boiler room largely depends on this.

Chimney and boiler installation requirements

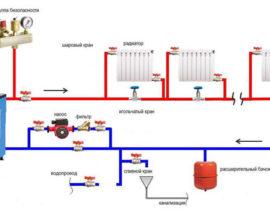

Combined boilers, according to the rules of their operation, have some features that differ somewhat from simpler designs of heating appliances. These nuances need to be known though would to ensure that the device is safe for everyday use.

- The main condition for installation is a properly equipped chimney pipe. It should be arranged in the same way as for a wood-burning stove.

- It should have good traction, but will provide her the required height of the pipe head rising above the roof. it distance should be at least half a meter.

- A very important condition is the flow of air into the blower chamber. To prevent carbon monoxide from entering the room from unburnt fuel, possibly have to provide ventilation. It will help burn the fuel to the end and remove all the resulting combustion products into the ventilation pipe.

- Chimney the pipe must be well insulated so that condensation does not form in the cold season from the difference between hot outgoing air and cold outside air. The accumulated moisture in the pipe can lead to the formation of ice blocking the smoke outlet. To prevent this from happening, the chimney must be insulated immediately after installing the boiler.

- Such boiler should be located in a separate room (boiler room) - in this case, its operation will be safer.

- It must also be remembered that the weight of the heating boiler — big enough and maybe is even several hundred kilograms. This must be taken into account when installing it, since not every floor is able to withstand such a load, and, Maybe, his have to strengthen. The floor or a special foundation must be reinforced concrete, otherwise they may simply sag.

Single-circuit heating boiler on wood and electricity

To install such a boiler, it is better to contact the masters working on this profile for help. They will competently advise the best model of the device, and install it without any problems, based on safety rules and technology requirements.