An autonomous heating system allows you to heat your home at minimal cost. The gas boiler is convenient, simple and unpretentious in operation, but in some cases it may spontaneously fade. There are many reasons for this, but the most common one concerns wind blowing. Why this happens, how to fix it and what nuances should be taken into account in the future, we will analyze further.

Content

- Causes of wind blowing the boiler

- How to identify the problem?

- How to solve a problem?

- Boilers with coaxial chimney

- Chimney extension

- Mounting the deflector

- Gradual heating of the boiler

- General Tips and Tricks

- Frequently asked questions and answers

- Video review of the reasons for blowing the boiler with wind

Causes of wind blowing the boiler

If in apartment buildings the heating system is mounted in a coaxial duct, which prevents wind from entering it, in private houses the problem of attenuation during strong gusts is quite common.

The design features of the chimney are to blame, as well as predisposing factors:

- There are trees next to the duct - with strong gusts of wind, vortex gusts are created that change the draft in the chimney, which leads to fluctuations in the burner wick and, accordingly, the flame disappears.

- Predominance of downdrafts as well as incorrect level and height of the chimney - this is especially true for single-standing private houses (dachas, cottages), next to which there are no other buildings.

- Insufficient chimney height, at which gusty wind easily extinguishes the flame of the burner.

- Traction Sensor Malfunctions, which gives false indicators that provoke the operation of automation that blocks the gas supply to the combustion chamber.

- Chimney depressurization, in particular, an open inspection hole, which forms a reverse thrust and triggers traction control sensors that signal the need for an emergency shutdown of the gas supply to the system.

- Incorrect chimney designwhen the required number of turns is missing and the wind from outside freely enters the boiler.

Also, the reason for the attenuation of the boiler in strong winds can be reverse thrust. If the boiler is installed near a balcony door, if the wind is gusty, when the door is opened, a strong draft will be created, which will cause the wick to oscillate and die out.

How to identify the problem?

Since the boiler can go out due to various malfunctions, it is possible to understand that the wind was the cause by the following signs:

- The boiler stops working only in strong winds, and on other days it works properly.

- Oscillation of the burner flame towards the exit, change in its height in the presence of a strong wind outside. Normally, external factors do not a priori affect the operation of the boiler and burner in particular.

- A pronounced whistling sound in the combustion chamber, which changes its intensity and severity with various gusts of wind and completely disappears in calm calm weather.

How to solve a problem?

It is strictly forbidden to make adjustments to the operation of gas equipment and ventilation systems without experience and skills. If a the boiler often goes out and the reason for this is strong gusts of wind - it is necessary to contact specialists who will find the cause (and there may be several) and eliminate it without endangering the life and health of the inhabitants of the house.

Boilers with coaxial chimney

If a gas boiler has a side chimney (usually in apartments) and goes out from strong gusts of wind, the main reason lies in the formation of condensate and ice. In practice, the situation is as follows: when the exhaust gas exits the pipe, it cools very quickly and settles on the inner walls in the form of an ice crust, which rapidly increases its thickness.

Outwardly, this does not manifest itself in any way, with the exception of a few icicles hanging out of the pipe, but in fact the natural removal of waste products is disrupted, which negatively affects the operation of the boiler itself. Swirls are created that lead to oxygen starvation of the gas chamber, respectively, the process of gas combustion is disturbed or completely stopped.

The problem is often found in regions where winter temperatures are over -30°C. Experts recommend installing heaters on pipes from the outside, which minimize icing of condensate. With pronounced accumulations of ice, mechanical thawing is required using special devices, so it is better to call the gas service to solve this problem.

If the design features of the boiler with a side chimney do not imply the presence of a deflector, then it should be installed independently. This is necessary in cases where the number of windy days per year is more than 200.A device that cuts off vortex air flows. Installed on the air intake pipe.

Chimney extension

Increasing the height of the chimney is appropriate when other buildings or tall trees are located next to the house, affecting the draft in the pipe. The procedure involves putting on an existing chimney pipe several pipes with a cross section of 0.5 more than the chimney itself. It is important to remember that the height of the chimney depends entirely on the design of the roof and the power of the boiler.

The average height of the chimney from the boiler grate is 5-6 m. This value can be increased taking into account the surface of the roof.

Only professionals should carry out work on increasing the height, since there is a risk of getting the opposite effect:

- A high chimney provokes an increase in traction, respectively, most of the heat will literally “fly out into the chimney”.

- The amount of condensate increases, which at negative temperatures will freeze on the inner wall of the chimney. This is fraught with a violation of natural air exchange and the operation of an automatic shutdown of the gas supply.

Mounting the deflector

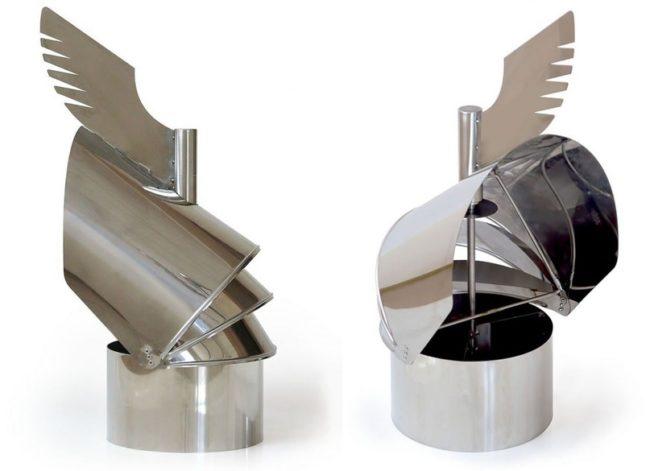

The deflector is an aerodynamically shaped nozzle that is put on the chimney. Made from stainless or galvanized steel.

Performs several functions at the same time:

- Protects from the ingress of debris, precipitation and dust into the chimney - it has a cone-shaped top.

- Blocks gusts of wind, cutting them off - prevents the vortex from entering the chimney.

- Increases draft by 10-20%, which allows you to solve the problem without increasing the height of the chimney pipe.

The process of installing the deflector will not cause difficulties, and the effectiveness can be assessed almost immediately.In regions where winds predominate, this design is necessary and is included in the gas heating system.

There are several types of deflectors, each of which has its own characteristics, advantages and disadvantages.

TsAGI

Metal pipe with shielding cylinder. Inside it has a protective cone, which excludes blowing from above and from the sides.

Advantages:

- Protects from precipitation

- Prevents debris from entering the pipe

- Easy installation

Flaws:

- In severe frosts, it provokes the formation of severe frost

Grigorovich deflector

A truncated cone with an extension at the base and a mushroom-shaped lid at the top. The air flow enters under the top cover, discharging the air and increasing traction.

Advantages:

- Protects from debris and rain

- Relatively low cost

Flaws:

- Not effective in low wind

Vane deflector

Contains a weather vane and several metal canopies that rotate in the direction of the wind.

Advantages:

- Enhances natural traction

- Protects against blowing from all sides

- Blocks rainfall

Flaws:

- Not found

Gradual heating of the boiler

If the gas heating system is used in country houses and has been inoperative for a long time, even weak gusts of wind can cause the flame to fade.

The problem is solved by gradually heating the boiler, namely, first, after ignition, set the minimum temperature values, after 5-10 minutes add gas, and after 20-30 minutes heat the chimney at high rates. This will allow the chimney to fully warm up, which will facilitate the discharge of the exhaust gas up the chimney.

General Tips and Tricks

If the gas boiler is blown by the wind, pay attention to the following nuances:

- Check if the boiler is operating at minimum temperatures. It makes sense to add gas by 20-30% to increase natural traction.

- Be sure to call specialists who will not only find the problem, but also diagnose the entire heating system.

- Clean the chimney in a timely manner, as dirt can form inside over time.

It is not recommended to independently inspect the combustion chamber, change the burner parameters or correct the operation of the control sensors. This may cause malfunctions in the future. All work relating to gas equipment must be carried out by qualified specialists.

Frequently asked questions and answers

There may be a problem in the backdraft valve, but to be sure, it is necessary to revise the nozzle burner. Also, attention should be paid to the control sensors. Over time, they fail and are not able to timely generate a signal about the need for an emergency shutdown of the gas supply to the system, from where the characteristic smell appears.

This is characteristic of an increase in natural traction, the reasons for which are many. It is necessary to inspect the hood, as well as the burner itself, adjusting the gas supply and flame height. If there are strong gusts of wind outside and the attenuation problem appears very often, a deflector is installed on the hood (chimney), which cuts off the vortex air flows.

In conclusion, it is worth noting that the problem with blowing out the boiler periodically manifests itself among residents of apartment buildings.As for private mansions, the attenuation is caused by improper chimney design or insufficient chimney draft.

In resolving the issue, it is important to make sure that the burner and control sensors are working, as they can indirectly help stop the combustion process. All work must be carried out by qualified personnel.

Video review of the reasons for blowing the boiler with wind