In order for the heated water to fully circulate in a closed system, a certain pressure is needed. Usually for home use boilers, these values \u200b\u200brange from 1.5 to 2 bar.

A decrease in these indicators leads to the fact that the coolant does not have time to heat up and move through the system, creating an impressive temperature difference at the inlet and outlet. This leads to an automatic shutdown of the boiler and the termination of the heating system. Why this happens and how you can deal with the problem, we will analyze it step by step.

Content

- How to check pressure?

- Open make-up tap

- How to recognize?

- What to do?

- Coolant leakage

- How to recognize?

- What to do?

- Expansion tank malfunction

- How to recognize?

- What to do?

- Airing the system

- How to recognize?

- What to do?

- Malfunctions of the pressure gauge and boiler automation

- Prevention of pressure drop in the boiler

- Questions and answers

- Video review of the reasons for the pressure drop in the gas boiler

How to check pressure?

Each boiler has a manometer that displays the pressure of the heating system. The initial setup is carried out by a representative of the company with which a contract was concluded for the installation and maintenance of gas equipment. As the temperature rises, the pressure also rises. If gas is added, but the pressure does not increase (the system itself does not hold the set pressure), then you need to look for reasons.

In each boiler, the pressure sensors are different, as well as the recommended parameters. In the instruction manual you can find all the recommendations regarding the norms of pressure gauge values.

The control sensor can be displayed on a common display or located inside the structure. In any case, it performs the only function - to control the pressure in the system, and if it is low, then the heating, or rather the lack of heat, will make itself felt.

Open make-up tap

If there is no expansion tank in the heating system and the water is filled directly from the water supply, it is important not to forget to close the tap. As soon as the pressure in the system has reached the desired level (depending on the boiler), the valve is closed.

If there is no expansion tank in the heating system and the water is filled directly from the water supply, it is important not to forget to close the tap. As soon as the pressure in the system has reached the desired level (depending on the boiler), the valve is closed.

What happens if this is not done? As long as there is water in the water supply, pressure is created in the system and everything is fine. One has only to turn off the water supply, and it can leave the circuit through an open tap, which will stop the boiler from working.

The situation is similar with double-circuit boilers. The absence of water when the tap is closed is hardly noticeable, but if you open the hot water valve, the coolant will leave, which will lead to a sharp drop in pressure.

How to recognize?

The sequence of actions is as follows:

- Check for cold water in the pipeline.

- Pay attention to the smell of hot water (when operating a double-circuit boiler). If it smells unpleasantly of rust and mustiness, has a yellowish or gray tint, then this water is definitely from the heating system.

- Check if the faucet valve for feeding the system is closed.

What to do?

If the water is gone and you missed this moment, the only thing you can do is wait for it to turn on.After that, you should fill the system and start the boiler, checking if the valve is closed. If the pressure gradually drops, be sure to check the serviceability of the faucet itself. It can pass a small amount of water that will seep into the pipeline when the water is first turned off.

Coolant leakage

A leak involves a depressurization of the system in any of its sections (especially at the joints), which leads to the release of water and a decrease in its amount. This leads to a drop in pressure, which can be restored by replenishing the deficit. The problem is more often faced by owners of aluminum radiators, which quickly oxidize during operation.

How to recognize?

To find a leak, and this is not so easy, you need to audit. For this:

- Take a napkin and blot all the pipe joints from the boiler to the final radiator. If there is a leak, the napkin will display drops of liquid.

- Carefully inspect the radiators and the floor underneath them. The presence of stains, dry and rusty spots are signs of a leak. Run your hand along the bottom and shine a flashlight. There should be no deformation or color changes.

- Check the faucets. Sometimes they pass liquid, albeit in small quantities, but over time this leads to the need to add it to the system.

Do not forget to check the boiler itself for leaks. All joints must be completely dry.

What to do?

The problem is solved by adding fluid to the system, but first you need to fix the leak itself.

To do this, follow these tips:

Leak in the radiator section - turn off the heating, drain the water as much as possible, then disconnect the battery. Mark the leak, dry it, clean it and seal it with cold welding.If the hole is too large, then you can simply remove this section by separating them from each other.

Leak in the radiator section - turn off the heating, drain the water as much as possible, then disconnect the battery. Mark the leak, dry it, clean it and seal it with cold welding.If the hole is too large, then you can simply remove this section by separating them from each other.- Leak in panel radiator - you can try to seal the leak with cold welding, but in most cases you will have to replace the panel with a new one.

- Leak at joints - soldered structures are cut off, and a blank is made from a new piece of pipe that is suitable in size. Soldering is done with a special soldering iron.

- Leak in faucets - replacing the element with a new one.

Expansion tank malfunction

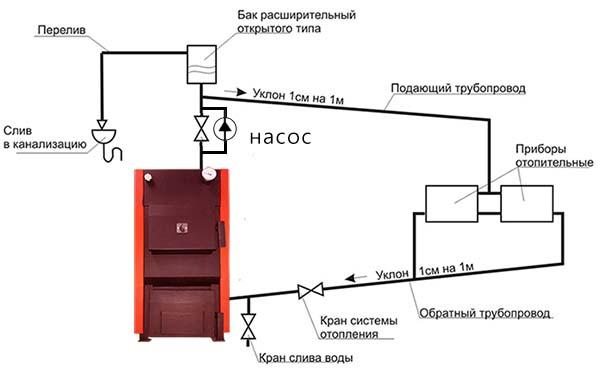

Sometimes the problem of pressure drop is connected with the expansion tank. It can be built into the boiler body, or it can be located outside it (then water is poured manually through the reservoir). If there are signs of a malfunction of this element, pumping with pressure measurements will be required.

How to recognize?

There are two main features:

- You often have to add water to the system, and there are no leaks along the circuit.

- A sharp and abrupt change in pressure on the pressure gauge dial when using hot water (only for double-circuit boilers).

Expansion tanks have a primitive structure, but even here malfunctions can occur that can reduce the pressure in the boiler and provoke its shutdown.

What to do?

The sequence of actions is as follows:

Close the water inlet and outlet taps from the system.

Close the water inlet and outlet taps from the system.- Drain the water from the system until the pressure gauge in the boiler reads zero.

- Record the pressure readings in the expansion tank with the valve open.

- Connect a conventional hand pump and pump pressure until water flows out of the tank by gravity.

- Pump out all the water from the tank.

- Release the air, then run the coolant into the system, equalizing the pressure to the recommended 1.1-1.3 bar (on the expansion tank).

Airing the system

Air getting into the system is inevitable. No matter how well the installation work is done, there is always a little air in the circuit. Most often, the cause is not cracks in the radiators, but the use of aluminum batteries.

Few people know (and sellers don't always talk about it), but aluminum, upon contact with water, enters into an oxidation reaction, which results in the release of hydrogen.

As a result, we have the following: there is less coolant, hydrogen exits through the valves on the radiator, and the pressure in the system drops.

Before using the heating system, be sure to check the radiators for the presence of air. A matter of minutes will help avoid serious problems with the equipment and protect against costly repairs.

How to recognize?

Signs of the presence of a large amount of air in the system are:

- The batteries are too hot at the minimum values of the boiler - the air heats up faster than the water.

- Often the boiler goes out - a temperature difference is created at which the automation is triggered.

- The pressure on the pressure gauge changes abruptly.

Airiness leads to the accumulation of air in certain parts of the radiators, forming air pockets. Because of them, certain parts of the batteries remain colder than others. And if you put your ear to the battery, you can clearly hear gurgling and squelching.

What to do?

The problem is solved very simply: you need to release excess air and add water to the system. For this:

- FROM

Using a wrench, carefully open the bleeders on the tops of the radiators.This should be done starting from the closing battery towards the boiler.

Using a wrench, carefully open the bleeders on the tops of the radiators.This should be done starting from the closing battery towards the boiler. - Substitute a container under them, as part of the water will come out with the air.

- Get ready that during the procedure there will be hissing and hot water together with steam can lead to a burn. Let the system cool down for 15-20 minutes.

- Close the drains with the key and open the valve for filling the system with water or add the coolant manually.

- Check the pressure, then start the heating.

Such a simple manipulation will equalize the pressure and solve the problem.

Malfunctions of the pressure gauge and boiler automation

If all possible causes of a decrease in pressure in the system have been eliminated, and the boiler continues to go out from low values on the pressure gauge, you need to make sure that it is working. You can test this measuring device only on special equipment, so you can’t do without calling specialists.

In some cases, the problem lies in the central control board, which generates incorrect signals that affect the pressure in the system. You will need a complete diagnosis that will answer all questions.

Prevention of pressure drop in the boiler

In order for the heating system to function properly and be safe for life, you need:

- Before buying a boiler, be sure to correctly calculate its power. For a two-story house, a small 7 kW parapet boiler will obviously not be enough.

- Mounting and installation, as well as the first start-up, must be carried out by professionals with special permission.

- The pressure is set in accordance with the standards and requirements specified by the manufacturer in the instruction manual.

- Do not ignore the periodic cleaning of the system and the boiler itself using special tools.

- Annually undergo a scheduled inspection of gas equipment, which will eliminate the development of a breakdown at the most inopportune moment.

And remember the main thing: if the pressure drops constantly, then you need to look for a reason that lies deeper than the airing of the system and the malfunction of the expansion tank. You will be helped by specialists who will diagnose and help in solving this issue.

Questions and answers

It is necessary to check the operation of the expansion tank. To do this, you need to pump the pump with fixing the data of its pressure. If for some reason it does not hold pressure even in the absence of water, a replacement will be required.

If the pressure on the pressure gauge drops and there is not enough fluid in the system, you need to look for a leak. Perhaps these are small holes, the water from which immediately evaporates, so you do not see the expected puddles. Check all joints and radiators, and then diagnose the expansion tank itself.

Such signs indicate the descent of water from the system into the central water supply. Check if the make-up tap is closed and that it is working properly.

Video review of the reasons for the pressure drop in the gas boiler