Natural gas continues to be the most profitable heat carrier, and a gas boiler is the most convenient equipment for heating a private house. Owners of gas boilers at least once encountered or heard about such an unpleasant phenomenon as the spontaneous attenuation of a gas boiler.

And although the automation of modern devices excludes the supply of gas when the burner flame disappears, the house cools down in winter quite quickly. In the absence of owners, the water in the pipes of the heating system can freeze, which will lead to catastrophic consequences. Therefore, if you observe episodic or regular attenuation of the boiler, you need to find out the cause and find a way out.

Content

- Why does a gas boiler go out?

- Clogged igniter and burner nozzles

- Faulty solenoid valve or thermocouple

- Lack of air draft in the system

- Outlet pipe, reverse draft and wind

- Lack of air for burning gas

- Pressure drop in the gas line

- Attenuation problems in closed-type gas boilers

- Question answer

- Video review of the reasons for the extinction of a gas boiler

Why does a gas boiler go out?

Unfortunately, it is not always convenient to call a gas service master, and sometimes it takes a long time to wait for his visit. However, there are a number of cases when you can fix the problem yourself. In other situations, on the contrary, even the visit of a professional will not save - if the weather with a strong squally wind or the wrong arrangement and placement of the gas outlet pipe are to blame.

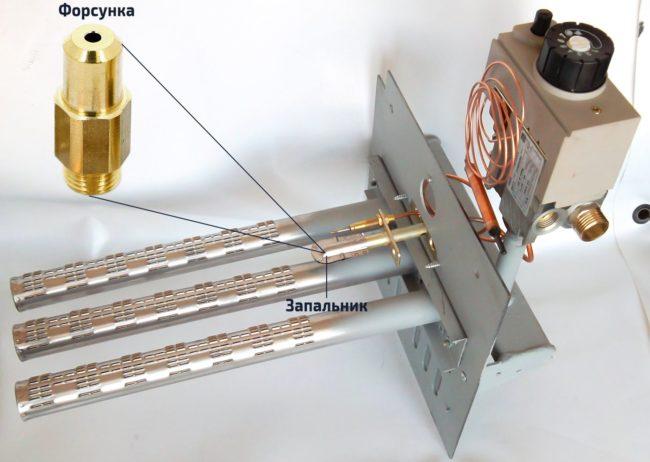

Clogged igniter and burner nozzles

Natural gas, which runs in domestic highways, is not a 100% pure substance - it contains additives and impurities. Some of them are added intentionally (for example, to give rise to a specific "smell of gas"), others are formed as a result of careless cleaning.

Yes, and the gas itself (a mixture of methane and in small quantities - propane, butane and ethane) burns out not without residue - the hours of operation of the burner generate soot and soot, which gradually settles on the parts of the boiler and can lead to clogging and blockage of thin channels and holes - jets , through which gas is supplied to the igniter and the burner itself.

The atmospheric boiler igniter is a special device that allows a small fire to burn. When the gas supply is turned on cyclically, it is he who ignites the mixture supplied from the burner. A constantly burning "wick" smokes even more than a burner, since the pressure in the igniter is low. If the soot clogs the igniter jet, the boiler will not be able to turn on the next time.

A sure sign of clogging and sooting of the igniter is the yellow color of the flame. Therefore, the igniter must be cleaned in a timely manner to prevent channel blockage.

The burner nozzles are much less likely to clog, since the gas is supplied there under pressure in large portions, but this situation cannot be completely excluded.

Faulty solenoid valve or thermocouple

Automatic gas supply, even in the simplest outdoor atmospheric boilers, includes a solenoid valve that opens the gas supply and a thermocouple.

A thermocouple is essentially a metal sensor that monitors the presence of temperature, sends a signal about it to the solenoid valve, and that, in turn, opens the gas supply to the burner. The thermocouple registers the operation of the igniter.

If the igniter works, but it is faulty, then the boiler will go out and more won't turn on without restarting or never at all (depending on the degree of failure). The same will happen if the cause is in the solenoid valve - even if there is a signal from the thermocouple, the gas supply can be stopped.

Both the thermocouple and the solenoid valve can be changed independently with the appropriate tools and skill. However, in the absence of experience, it is still recommended to resort to the services of a master, since the normal operation of the boiler.

Lack of air draft in the system

The atmospheric gas boiler operates on the same principle as its ancestors - coal and wood stoves. Natural gas burns when air enters, and combustion products are carried out through the chimney outside the house.

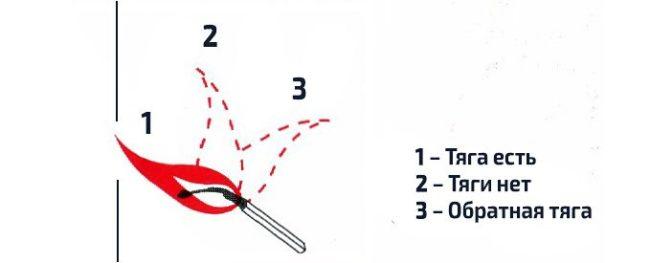

In order for the whole system to work successfully, draft is necessary - a constant flow of air from the boiler burner to the chimney head. If there is no draft, the combustion products will not leave the combustion chamber at the required speed, and the boiler will go out.

Next, remove or disassemble the outlet pipe to the chimney. In modern boilers, it is enough to loosen a couple of screws or loosen special quick assembly clamps. After checking the draft, it becomes clear where the reason for its absence is in the boiler itself or in the chimney.

The chimney during operation is not only clogged with soot and other combustion products.Birds or collective insects (for example, wasps) can get into it accidentally or intentionally, by making a nest. This happens in the summer when the chimney is idle.

Outlet pipe, reverse draft and wind

A case worth considering especially is the incorrect arrangement of the chimney outlet pipe, which creates reverse draft. The fact is that air flows can, reflected from obstacles located near the pipe head, blow out combustion products back into the chimney and extinguish the burner flame.

Such obstacles can be densely growing tall trees, the wall of the house or the ridge of the roof. In the second and third cases, the reason is the incorrect placement of the end section of the chimney. The correct location is above the highest point of the house.

Sometimes in nature there is such a phenomenon as a downward wind. Its flows are not directed horizontally, but at an angle to the earth's surface, sometimes almost at a right angle. This means that a strong gust will blow from top to bottom directly into the pipe and, regardless of the location of the head, will return gases to the chimney.

In order to compensate for the downward wind phenomenon, there is only one way - to cover the head with a fungus, leaving a sufficient distance for the burnt gases to escape.

Lack of air for burning gas

The problem is related to the lack of traction. Even if the boiler and chimney are in order, the lack of fresh air entering the combustion chamber of the burner can lead to the extinction of the flame.

From the school physics course, we know that oxygen is required for combustion. The powerful flame of the burner quickly burns it out of the air, turning it into carbon dioxide.If very little new air enters, then the combustion stops, the flame subsides, and the automation turns off the gas supply.

The reason for the lack of air in the room where the boiler is located may be:

- tightly closed windows with seals;

- pretended solid doors with a high threshold;

- improperly organized ventilation (air is taken in by an exhaust hood, exhaust fan or other active devices).

Pressure drop in the gas line

If the gas is not supplied under the required pressure, the burner goes out and does not turn on. The reason for the drop in pressure may be routine maintenance on the gas pipeline or a leak. The latter can occur outside the site or on its territory.

Carefully check the gas supply along the entire length of the pipe. If there is a leak somewhere, the smell of gas and hiss will tell you everything. If you find a leak, do not try to fix it yourself! Call the gas service.

Sometimes the cause of insufficient pressure at the inlet to the boiler can be a clogged or faulty meter. Since it is sealed and it will not work to disconnect the pipe, you will also have to call specialists to check it.

Attenuation problems in closed-type gas boilers

If in atmospheric boilers a lot depends on external factors - wind, draft, features of the chimney, then in devices with a closed chamber, air is forced in with the help of a special turbine, and combustion products are brought out in the same way. For these purposes, a coaxial chimney is used, which can be placed in any part of the house.

Therefore, the attenuation of turbocharged gas boilers is specific.Most often, it is caused by freezing of the external pipes of the outlet channel, because in the coaxial chimney the cold air inlet is adjacent to the hot exhaust manifold. As a result, frost forms in the winter season, which can eventually clog the channel so much that the automation will turn off the burner.

Another reason lies in the very design of the boiler. Failure of the turbine or blower will lead to the failure of the entire system, since boilers with a closed burner cannot work as atmospheric ones.

Question answer

No, it doesn't. Rather, the configuration and location of the pipe is decisive.

SNiPs prohibit the installation of deflectors and caps of the upper location on the chimneys of gas boilers. However, sometimes mounting them is the only way to compensate for backdraft due to wind.

You have to start from the situation. If we are dealing with an aspirated engine and the burner is blown out by the wind, then a restart is needed. If there is a suspicion of a leak in the house, it is better to wait for the arrival of the gas service.

The best option is active supply ventilation in the form of a ventilation duct equipped with a fan. For low-power boilers, a passive one is also suitable - in the form of ventilation grilles.

In addition to the above reasons, double-circuit boilers can go out if the tightness between the heating and hot water circuits is broken in them.

The attenuation of a gas boiler is an unpleasant incident that can happen even with a properly designed system and perfect technology. However, systematic attenuation is a reason look for the reason and eliminate it.

Video review of the reasons for the extinction of a gas boiler