Alas, but for now more Not everyone inhabited points or summer cottages settlements got access to the main gas supply.

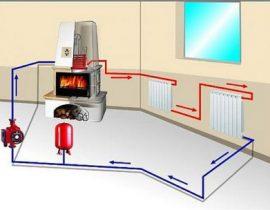

How to solve the problem of heating a home in such conditions? to heat the house stoves or boilers for solid fuel is not to everyone's liking - this requires both constant monitoring and extra hassle by byreplenishment of energy resources.

Luckily there is electricity. practically everywhere, electric heating boilers from a 220 volt network come to the rescue, but how safe and economical are they?

The prevailing stereotype - at the mention of electricity as a source of energy for heating a house, the majority immediately has an idea of extremely uneconomical systems and fabulous utility bills. This will be true if we keep in mind the old models of boilers with heating elements. However, this can be argued if modern equipment is used that uses completely different methods of converting electrical energy into thermal energy.

So, the modern market for heating equipment is represented by classic heating elements, electrode and induction boilers of various types. This The publication focuses specifically on new technologies for heating installations that use network electricity.

Content

TEN - simple, but very uneconomical, is it possible to heat a house with it?

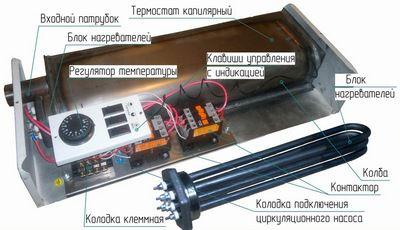

The simplest in design are water heaters that use the resistive principle of energy conversion. In other words, they are familiar heating elements, and the principle of their operation differs little from the usual incandescent bulbs, electric stoves, kettles or irons. The heat source is a spiral (conductor) made of a metal having a high resistivity.

The current passing through the spiral causes a fast her heat. However, in the case of a water boiler, the spiral must be “dressed” in a dielectric insulator and then in a waterproof case (this is an exemplary device of any heating element). Each layer is heat loss, and as a result, the efficiency reaches 75 at best.—80%. In addition, the heating of the coolant occurs slowly enough that more significantly reduces the efficiency of such boilers. Such a scheme justifies itself in storage water heaters, but for heating purposes it looks extremely unprofitable.

No doubt, modern boilers are literally crammed with electronics that maximize the performance of devices. Thus, the possibility of stepwise operation of several heating elements, depending on the temperature of the coolant, if the automation "sees" that this will be enough to maintain the set mode. Manufacturers sometimes declare 98% efficiency of their products, but judging according to reviews, pay for electricity when using such boilers as the main source of heating have to a lot.

The main advantage of such boilers is their low price. If you install it as a "help" or for occasional inclusion, for example, during temporary visits to a country cottage in the cold season, then the purchase will be justified.

Heating boiler with electrode circuit

AT his time, electric boilers of a detailed type of action were widely advertised, presented as the most optimal method of using electricity to heat a home. Simultaneously went a stream of not the best reviews about their work. Where is the truth? She, as usual, is somewhere in the middle.

The principle of their operation is based on the electrical conductivity of a liquid with certain chemical and physical properties - electrolyte. Fast phase change (50 vibrations per second, those. 50 Hz) leads to oscillatory movements of ions and rapid heating of the coolant.

A similar scheme of work attaches such boilers whole line advantages:

- high rate of temperature rise, those. the device has a very low inertia.

- Safety - the installation, in principle, will not be able to work with absence coolant (for example, when it leaks).

- Such boilers are completely “indifferent” to voltage drops in the network.

- The cost of equipment is low.

However, the virtues are blurred serious disadvantages:

- An autonomous heating system will require a very precisely verified chemical composition of the coolant, otherwise all the declared advantages will simply lose their meaning.

- The heating power is extremely unstable - it directly depends and from chemical composition of the coolant, and from its current temperature, which significantly changes the conductivity of the electrolyte.

- In light of these two reasons — very great difficulties in fine-tuning or automating the heating process.

In addition, reviews of such a system are unanimous in that it requires frequent (not less once a year) call a specialist to clean the heat exchanger plates and adjust the chemical composition of the electrolyte. And myself boiler, and heating communications, and radiators of an autonomous system quickly overgrow with salts and need preventive work. And more one important point - an indispensable properly equipped ground loop - without it boiler it just won't work.

Induction boilers - modern approaches to the problem of electric heating

Perhaps the most productive among all electric heating boilers for 200 AT are installations using the principle of electromagnetic induction.

It is known from the course of physics that if an alternating current passes through one conductor (primary winding), then a potential difference (voltage) is induced in the secondary winding located in the created EMF. In the event of a short circuit in the secondary circuit, a current begins to flow through it, which is used as a source of thermal energy. Simply put, the usual electrical transformer circuit, which is adapted for the needs of heating the coolant.

What are the main advantages of induction heaters?

- They have virtually no vulnerable parts or components that will require frequent replacement or repair. So, in ordinary boilers it is heating elements due to constant cycles of heating and cooling, they wear out the fastest, and this is associated with the need for their periodic replacement. In induction boilers, the coil that creates an electromagnetic field does not come into contact with the heated medium in any way, and can serve for many years without the risk of an interturn short circuit.

- Boilers heating elements or electrode ones have a common disease - overgrowth of working elements with layers of scale, which sharply reduces KPD pribors. The operation of induction heaters does not have such a drawback - it is accompanied by high-frequency vibrations, microvibration, which do not allow the formation of layers of oxides or salts.

- Heating systems with induction boilers absolutely not demanding to the chemical composition of the coolant.

- The operation of such boilers can be easily adjusted and automation is usually, electronic control units are included in the scope of delivery of the product.

- Heating of the coolant to the set temperature occurs very quickly - after 5—7 minutes.

- Produced calculations show that such a scheme gives up to 30—40% energy savings compared to other boilers of the same capacity.

- Induction boilers are characterized by increased eletro- and fire safety.

- Life time boiler, in most cases, depends only on quality welded joints. Such heaters can serve trouble-free for 30 years or more.

Modern induction boilers mostly performed according to one of two schemes - SAV or BIN. Induction basic principle is the same, but in matters of organization of heat exchange and design, there is a fairly significant difference between them.

Type electric boilers SAV

The function of the secondary winding in given case beret a short-circuited system of channels and pipes with a heat carrier. The induction alternating current generated in it entails rapid heating of the heat exchanger surfaces with the liquid circulating through them, which is pumped into the heating system. The inner contour has very branched labyrinth structure, therefore heating occurs in very short timeframes, which Supreme efficiency boiler.

But this too more Not all. Even at low values of the current consumed from the external network, the law self-induction. A short-circuited "coil" of heat exchanger pipes, located in an alternating electromagnetic field, in itself additionally induces reactive power, and the magnitude of these homing currents is very significant. It - more one plus to the efficiency and economy of the boiler.

Manufacturers produce a wide range of boilers SAV, from small ones, for space heating with a small area, to powerful units, which are even used in technological processes to maintain certain temperature regimes. For example, one of the most compact devices, boiler series "Prof»SAV-2.5:

- Product dimensions - a metal cylinder with a diameter of 12 cm, height 45 cm.

- The mass of the device is 23 kg (plus 4 kg - the weight of the electronic control unit).

- With such "modest" dimensions boiler has a power of 2.5 kW, which allows you to heat 25—30 square meters with standard ceiling height and good thermal insulation of the premises.

- The efficiency declared by the manufacturer is 99%.

- Installation of the boiler is not difficult - it equipped all necessary threaded pipes and flanges for tapping into the heating system.

- You can buy such a heater, together with a control unit, for 28—30 thousand rubles.

Type boilers BIN

Operation of the induction vortex heater (BIN) is organized somewhat differently. Mains voltage 220 V 50 Hz enters the electronic converter and is transformed into high-frequency. it gives sharp increase tension EMF and, accordingly, the amplification of the surface high-frequency Foucault currents generated in the magnetic circuits.

In connection with the fact that almost the entire boiler (body and internal tanks, pipelines) are made of special ferrimagnetic alloys, the emerging effect magnetization reversal leads to an almost instantaneous heating of all parts in contact with the coolant, and almost the entire rather massive design of the boiler acts as a heat exchanger - hence its enviable efficiency.

Externally, VIN boilers also represent a cylinder, of various diameters and heights, depending on the power of a particular model. For example, you can look at one of the smallest - boiler «BIN – 3»:

- Weight and dimensions of the product - 30 kg, cylinder Ø 122 mm, height 620 mm.

- Boiler power - 3kW 9 with heat dissipation 2520 kcal/hour. This is enough to effectively heat a room up to 40 square meters.

- The efficiency of such an installation is 99%.

Installation of the boiler is not difficult, and is easily carried out by the appropriate specialists. The scope of delivery usually includes boiler, stop valves, automation cabinet, temperature sensor and flow controller, pump for ensure forced circulation of the coolant.Such a kitBIN – 3” is worth the order 35 – 38 thousand rubles.

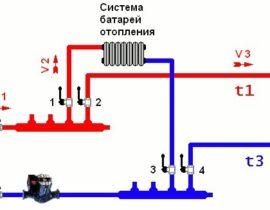

Often, induction heaters are combined into whole "batteries" in series. connected boilers, which allows them to be used for heating large areas.

- Of course, induction boilers also have their drawbacks:

- The price is quite high, but it should quickly pay off in savings on electricity bills.

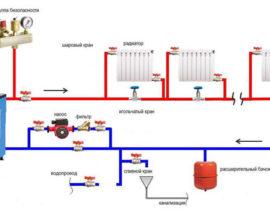

- Such boilers are installed only in closed heating systems with forced circulation, otherwise the entire efficiency effect is lost. There is more one caveat - open expansion tank will also affect the profitability of the system, so a membrane receiver is usually used.

Video demonstration safety of electric heating boilers of induction type

To summarize the publication, one can more once again emphasize that from the point of view of operating efficiency, boilers of the induction principle of operation unconditionally occupy the first place. Their prices are high, but taking into account the duration of trouble-free operation, the absence of the need for repair and maintenance work, ease of installation and management, low power consumption - this is perhaps - the most optimal option.