Currently, polypropylene pipes for heating are becoming the most popular material. And this is not only due to their aesthetic appearance. mind - reasons success lies in lightness installation and service life.

Today, specialized stores offer a considerable range of polypropylene pipes, from whom you can choose the type and color that is most fits for a specific heating system. Such pipes have their advantages and disadvantages, as well as features in the installation work. You need to know all this information - they will definitely come in handy when choosing, installing and operating a heating system with pipeline from polypropylene.

Content

Which type of polypropylene pipes last longer?

The material is propylene, from which the pipes are made, — it is a chemically inactive polymer supplied to production extrusion lines in the form granulate High Quality. It is specially designed for the manufacture of sanitary accessories for various purposes. — this is the circulation of a hot coolant, the transportation of cold water, the disposal of sewage waste, as well as the laying of communications for various chemical compositions, gas mixtures and etc..

Propylene has excellent physical and technical characteristics, easy lends itself installation, and therefore the demand for products from it is constantly growing. In addition to the pipes themselves, for each of their types, components are produced that are designed for mounting almost all the nodes and connections encountered - these are bends at various angles, adapters for different diameter and threaded connections, tees, plugs, valves, compensation loops and much more. Propylene compares favorably with polyethylene, from which some types of pipes are also made, in that it can withstand higher coolant temperatures, while having greater rigidity. These pipes are produced in different sizes. — depending on their purpose, it varies from sixteen millimeters to one hundred and ten. All types of propylene pipes have the same characteristics: their thermal conductivity is 0.24 W / m FROM, weight (specific) — 0.9 gr. per 1 cm³ (they are lighter than water), the elasticity is 900 N / mm², the viscosity of the material is 22 kJ. Basic mounting method polypropylene pipes - thermal welding (soldering), although in some units of the heating system design one cannot do without threaded mates.

Types of produced polypropylene pipes

Depending on the type of raw material used in extrusion in the production of pipes, they are divided into three main classes:

- The first of them is used most often for plumbing industrial mains and ventilation systems. PP PPH — so this material is marked, and produced He is from homo-propylene.

- The second variety is used for plumbing household wiring, for systems warm gender — it is labeled PPR RV and is made from block copolymer.

- The third type is used when installing heating systems — they function perfectly due to the evenly distributed load on the inner surfaces of the pipes. They are marked with a PP code. RRW, and similar products are made from stat copolymer.

Working temperature conditions of all three types of these pipes should not exceed 70—75 degrees. If this condition is met, they will function for a long time without causing problems. Besides propylene pipes can have a monolithic structure, or be reinforced with reinforcement. For heating, propylene pipes reinforced with fiberglass or aluminum foil, located in the thickness of the walls, are most often used. Therefore, when carrying out assembly welding work, it will not be necessary to clean the surface layer, which characteristic of installation of other types of pipes - with external reinforcement.

Do polypropylene pipes have disadvantages?

The disadvantages of polypropylene pipes are much less than the advantages, but they must be known and taken into account when choosing. So, one of the negative qualitiestv trdec of propylene can be considered the coefficient of expansion of the material — he is tall enough. When exposed to high temperatures, the pipeline may to begin sag, therefore, for heating systems and hot water supply, propylene pipes with mandatory aluminum reinforcement are used. It should be noted that the material manifests itself thus when heated above 60 degrees, and the standard temperature of the coolant in the central heating system is set at 70 degrees.

Undeniable positive qualities of polypropylene pipes

The positive qualities far outweigh the disadvantages of the propylene pipe. These include:

- complete neutrality of pipes to the chemical composition of the coolant and to external influences;

- long guaranteed service life, incomparable with any other material that constantly interacts directly not only with ordinary water, but also with a coolant, often containing aggressive chemical additives;

– a high level of strength and elasticity (even when the material is stretched, it is not damaged, but allows it to withstand significant loads during active operation);

- an important factor for many buyers is a low price, which is available to almost everyone;

- light weight of pipes, which allows them to be transported independently, without the involvement of freight transport;

- speed and ease installation of the system, which can be performed by one person, in the presence of necessary tools;

- pipes with aluminum reinforcement can withstand temperature conditions from —45 to + 90 degrees;

- the polymer is absolutely not subject to corrosion, so the water that is transported through such pipes will never be saturated with rust and salts rigidity;

- in an autonomous circuit of propylene pipes, oxygen is almost completely absent — this prolongs the life of batteries installed in given contour;

- due to the fact that by installing such pipes, you can use almost every fragment of them, even a very small one, the installation is waste-free, and means — very economical;

- the aesthetics of propylene pipes helps the heating system fit perfectly into any interior.

How to connect polypropylene pipes?

Working with any propylene pipes is easy and simply, their connection by soldering or threaded mates, when required, is not particularly difficult, and everyone can learn it. The material is cut with special scissors or a hacksaw, and the pipes are connected to each other by auxiliary connecting parts and soldering. soldering is enough reliable connection — such highways may well be embedded in walls, without fear for their integrity. If the threaded joints of metal pipes were the weakest point in the heating system, they required careful “packaging”, then the appearance of propylene products and the method of their connection — high-quality soldering, saved forever from this problem.

Work process

Mounting by soldering is quite easy if you use high-quality tools and clean, not defective connecting parts. An important condition for high-quality installation is compliance with the desired temperature. For everybody certain pipe diameter must be applied certain soldering temperature.If the pipes were outdoors or indoors with low or high temperatures, they must be kept indoors for at least 12 hours to adapt them to the conditions in which they will be installed.

Tools

For installation work, you will need special tools, and some of them cannot be replaced with other, improvised devices:

1. An apparatus for welding propylene pipes, having nozzles (couplings and mandrels) of different standardized diameters.

2. Pipe shears — at their absence fit hacksaw or jigsaw.

3. Folding rule and tape measure, as well as a marker for marks.

4. A sharp knife for cleaning the ends of pipes after they have been cut from burrs and chips. In addition, for these purposes, for trimming, you can use a special tool - shaver, with well-honed and exposed knives.

5. Besides, it is necessary to have a pre-compiled and carefully thought-out scheme of the heating circuit.

Mounting

- Starting work, the drawn up scheme-plan must be kept in front of your eyes all the time and, based on her, prepare individual parts of the contour. To do this, it is better to lay out the pipes along the walls along which the highways will go, and, measuring on the spot, prepare individual parts.

- Preparing pipes for certain site, install on the welding machine required nozzle and heat it up to necessary temperature, which depends on the diameter and type of material. Most modern welding machines have an extremely clear gradation on the built-in thermostat.

- Further a connecting element is tried on a pipe — it can be a coupling, tee, branch, tap, other shaped products.

- To control with a marker, make a mark on the depth of penetration. The pipe must not enter too deeply into the joint, but must be kept in German tightly. If this is a direct coupling, then inside her there is a ledge that will stop the pipe in the right place.

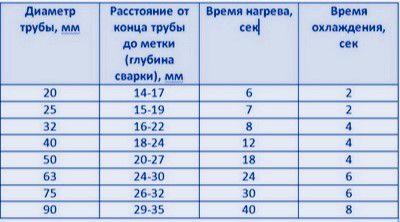

- The shaped connecting element and the end of the pipe are placed respectively on the mandrel and the coupling of the welding machine, so that they warm up at the same time, and the required heating time is noted, which depends on the size of the pipe diameter and on the thickness her walls. After waiting for the required interval, the parts are removed from the nozzles of the apparatus, then the pipe is progressively inserted into the coupling - twisting movements should not be made. The depth of penetration and holding time are shown in the table:

fastened parts must be cool. — it happens enough fast (data also shown in the table).

Fixing pipes to the wall

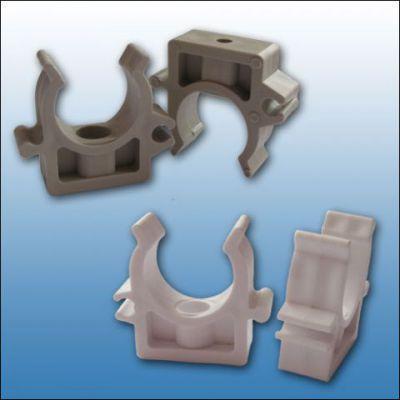

For fastening pipes to the wall, special fasteners are provided (they are often called clips), they are selected according to the diameter of the pipes and must fit exactly to them. There are fasteners that fix the position of the pipe motionlessly and provide her stable location. They also use a movably fixing fastener, in some places they cannot be dispensed with, for example, in long sections where pipes are subject to significant temperature expansion, take this into account not only when choosing the material of fasteners, but also the frequency of their use.

Retainers help the pipes withstand loads in the event of pressure build-up and prevent them from sagging.

Video: tips for choosing polypropylene pipes for heating

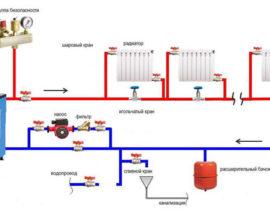

If you are going to install or replace a heating circuit, one of the surest decisions would be to choose polypropylene pipes as the main carrier of the coolant. The main thing is to take into account all the above characteristics and follow the installation technology. Do not rely heavily on the advice of sales assistants in stores, sometimes they advise an ignorant buyer exactly what knowledgeable specialists do not buy. If you are armed with knowledge, you will not be deceived, because you cannot deceive yourself!