Heating in the house, centralized or autonomous, not cost without pipes. Everyone remembers metal pipes, which have an unattractive appearance and can fail at any time, as over time they react worse and worse to temperature changes.

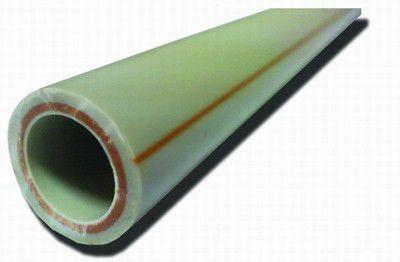

Reinforced polypropylene pipe in section

In addition, the metal quickly overgrows with scale from the inside, which slows down the movement of the coolant and reduces heat transfer, which in turn increases fuel consumption. Apparently, these disadvantages of metal products led the developers to the desire to create and put into practice new models of pipes made from modern materials based on advanced technologies.

Ordinary plastic pipes cannot be placed in heating systems with high pressure, because they are not so strong, but the developers found a solution - reinforcing an ordinary polypropylene pipe with fiberglass or aluminum significantly increases its strength and service life, in turn, such pipes are not without all the advantages of plastic ! Reinforced polypropylene pipes have become very popular among homeowners when installing the latest heating systems using the most modern boilers, pumps and various automation systems. They are perfect for pipeline both in the private sector and in high-rise buildings.

In addition to them, products made of polyvinyl chloride and polyethylene are produced, but they cannot be installed in heating and hot water systems. Yes, they will not be able to surpass polypropylene pipes, fortified with the help of reinforcement, according to its technical characteristics.

To ensure the effectiveness them exploitation before produce them purchase, you need to take a closer look at them characteristics.

Content

Types of reinforced pipes made of polypropylene

Reinforcement enhances the positive qualities of polypropylene pipes, making them more reliable and more resistant to chemical and aggressive environments, how internal — from the coolant, and outside.

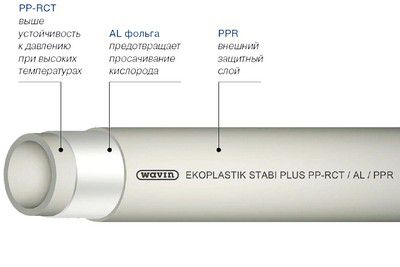

For heating, two types of multilayer pipes are used, consisting of three and five layers.

- AT three-layer pipe the middle layer is the reinforcement, which can be made of fiberglass, and maybe — from aluminium.

- five-layer type of pipes consist of two layers polypropylene — external and internal, as well as equipped reinforced layer, located in the middle, and two layers of heat-resistant glue.

Since both types are designed for heating systems under sufficiently high pressure, they respond to it as adequately as they do to high coolant temperatures.

Each pipe is marked her the housing contains numerical and alphabetic designations, by which it is possible to determine what material the reinforcement was made of.

Heating pipes with fiberglass reinforcement

Reinforcement fiberglass pipes from PP have the designation PPR-FB-PPR. Such marking shows that the products are made according to the multilayer principle, in which there is a reinforcement layer in the middle, which is noticeable on the pipe cut in the form of a red or blue stripe in the middle of the pipe. AT given In this case, fiberglass is used, and these products are usually called fiberglass.

The fiberglass layer comes in different colors, and this is clearly visible on the cut. But this is not a hallmark of the quality and other characteristics of the pipes, and does not affect their operation in any way.

- The advantage of the products equipped fiberglass reinforcement, in front of the aluminum layer, is an easier installation — they do not need to be calibrated and cleaned. Installation of this type of pipes saves a lot of time. Fiberglass products do not delaminate, because they have a monolithic structure, since fiberglass is simply fused into polypropylene.

- The weaknesses of these products include their greater expansion when heated, compared with products that have an aluminum layer. — it is more than 5—6%. But, despite this small flaw, they all equally more popular than pipes reinforced with aluminum because of the ease of installation and the absence of a fundamental difference in the period of operation.

Pipe with a layer of aluminum

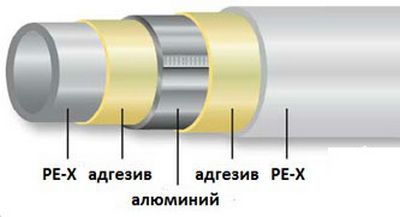

Pipes reinforced with an aluminum layer are abbreviated PPR-AL-PPR and are divided into several subspecies.

- In the first variant, perforated aluminum is installed in the middle part of the wall thickness of the product, those. round holes of small size are distributed throughout the reinforced layer.

- Another option is solid aluminum reinforcement without holes.

- If the two previous subspecies had three layers, then the third option includes five-layer pipes in which a hot-melt adhesive layer is distributed between polypropylene and aluminum on both sides.

During installation at the junction, aluminum is scraped off, since it cannot be soldered, only the pipe layer made of polypropylene is connected. A pipeline made of such pipes has been trouble-free for several decades, with their proper connection.

The middle aluminum layer, as well as fiberglass, can be of different colors. However, she also not notset no information about the quality or characteristics, so you should not pay special attention to it when buying.

Sometimes in the marking, the designation PPR is replaced by PEX and may look like this: PPR-AL-PEX, PPR-AL— PPR or PEX-AL-PEX. Such designations speak of several different structures. layers. The first letters in a combination of symbols — this is the outer layer of the pipe, then goes aluminum and the third designation of the inner layer. For example, a combination of letters PEX stands for cross-linked polyethylene - it has higher performance qualities. But, it must be said that, in principle, these pipes are almost the same and they can be safely used for heating circuits.

Characteristics

- PP pipes without reinforcement are not used for heating, as they have a large significant linear expansion when heated from a hot coolant. Therefore, one of the important characteristics for any reinforced products can be attributed to a small coefficient of thermal expansion — about one centimeter per linear metr truby. Material leads myself thus even at temperatures exceeding the standard value for central heating of 70 degrees.

- Due to the composition of the material used for the manufacture of PP pipes, they acquire high elasticity. For example, when the coolant freezes in them, they do not collapse, as is usually the case with metal. Same here let's attribute and thermal strength — they withstand temperature fluctuations from — 10 to +95 degrees.

- Mechanical strength can also be attributed to positive characteristics.

- Environmental safety is also important., how for humans and for the environment.

- It is very important to pay attention to the marking and find out what pressure the coolant is designed for. definite pipe type.

- Any type of polypropylene pipes outperforms metal pipes in their resistance to corrosion, regardless of the coolant used in the system.

- Polypropylene is chemically inert, therefore not enters in any reaction, which allows you to maintain the integrity of the pipeline for many years of operation.

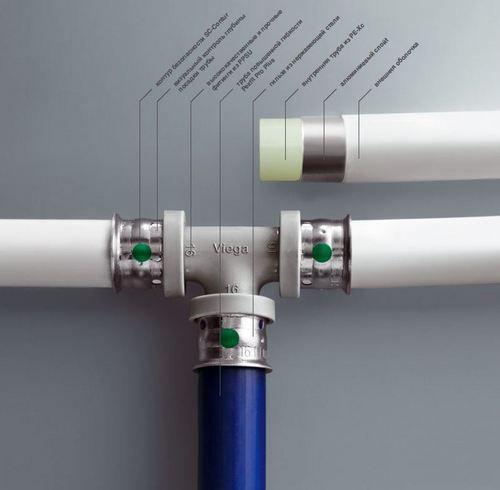

Accessories

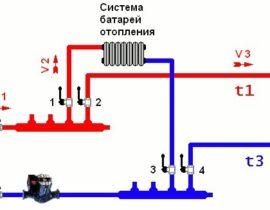

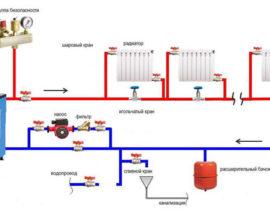

When installing any PP pipes, it is necessary to use various fittings for connection. All the necessary components are determined in advance, according to the drawing of the heating wiring.

The components include tees, fittings, couplings, bends, valves and other parts. They need to be selected based on the diametertr trub, which will be installed, and on their characteristics. For example, you can not purchase components for cold water systems for installation in heating circuits.

To interface with other, non-polypropylene sections of the system, special products are used with pressed-in threaded metal inserts or with captive nuts of the American type.

Installation of reinforced PP pipes

Installation of reinforced polypropylene pipes is quite simple, and it is quite possible to do it on your own if you have the necessary equipment for this. The main condition for joining — creation of a strong hermetic seam by melting the upper layer of the material.

Tools

The set of tools used during installation includes:

- soldering iron-heater — this is a special welding machine for soldering polypropylene;

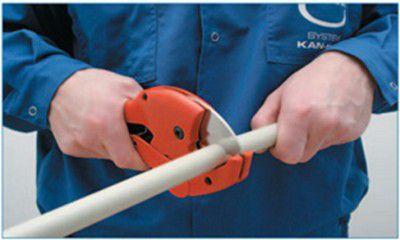

- a pipe cutter that will allow you to cut exactly at a right angle, which is very important for high-quality welding.

- if a pipe with aluminum reinforcement is used, then it is necessary shaver, with which the foil is removed before soldering and trimming (chamfering) is performed. The tool must have sharp and well-adjusted knives.

- measuring tool - square, tape measure, building level, marker.

If you plan to do reliable heating circuit, so that it lasts for many years without various problems, improvised fundsyou need specialized tools.

Preparing for installation

Before the installation of pipes in the system, short preparatory work is carried out. So that they do not drag out, a scheme of the entire wiring is drawn up in advance, accurate measurements are made and entered into the scheme. The parts necessary for connection are also indicated there, in the figure they are placed in the places where they will be located directly in the system:

- acting according to the scheme, measure and cut off sections pipes;

- with externaltheir them edges chamfer is removed;

- the place where the connection will take place is cleaned and degreased;

- the welding machine is fixed on a stand, and connected to the network, it must be heated to 255—260 degrees.

The heating time is determined according to a special table and depends on the type of part, wall thickness and pipe diameter.

How to solder reinforced polypropylene pipes

The parts are connected to each other as follows:

- Two parts prepared in advance for welding are taken. The penetration depth is marked on the pipe with a marker. After that, the shaped part is mounted on a cone-shaped element — mandrel, and the pipe is inserted into the sleeve to the set mark.

- After heating, the time of which is in strict accordance with the table, the parts are removed from the soldering iron heater and quickly connected to each other. You need to insert them progressively, without scrolling and without applying extra effort. After the joint cools down, a tight hermetic seam is formed.

- A correctly made connection does not require constant monitoring, such as, for example, for metal pipes with threaded connections. This can be considered an advantage of reinforced polypropylene products, because they can be embedded in a wall without fear of accidents.

- For laying heating lines in the wall, it is necessary to draw up an exact diagram of the passage of pipes by tying her to certain room and taking into account the characteristics of the material of the walls and ceilings of the building.

- The pipes are also placed along the wall, fixing them to it with special clamps (clips), which are screwed onto dowel. Pipes are inserted into the clamps and closed latch.

You need to know that it is impossible to connect polypropylene pipes directly to the boiler nozzle if heating is laid in a private house. The transition from polypropylene to the heater is made using a piece of steel pipe, length 45—50 centimeters.

Video tutorial on the device and installation of reinforced polypropylene pipes

Polypropylene reinforced pipes have proven themselves as lungs in installation and reliable in operation. Affordable, durable in operation, easy to install and more aesthetic than metal pipes, and does not require special control and painting — these virtuestv vpit's enough to choose for installation it is reinforced polypropylene.