Rust, salt deposits and other impurities circulating in pipes and heating radiators along with water gradually settle on internal surfaces. This prevents the flow of coolant and dramatically reduces heat transfer.

Aggressive deposits eventually begin to destroy the metal. As a result, fistulas and ruptures can form on pipes and batteries. Regular flushing to remove foreign particles from pipes and the boiler helps to avoid such a development of events and maintain the efficiency of the heating system.

Content

- Causes of blockages

- Signs of a clogged heating system

- Frequency of the procedure

- Cleaning methods

- mechanical cleaning

- Hydropercussion cleaning

- Chemical cleaning

- Top - 10 best chemicals for flushing the heating system

- DIXIS LUX

- ARGUS SUPER POWER

- G63

- Heat Guardex Cleaner 824R

- TELAKKA HEAT

- SYNTILOR Watesup

- SYNTILOR Watesup All

- SteelTEX ZINC

- GEB G30 Desembuant

- HeatGUARDEX Cleaner 808R

- Flushing the heating system with biological products

- How to Reduce the Risk of System Contamination

- FAQ

- Video tips for flushing heating systems

Causes of blockages

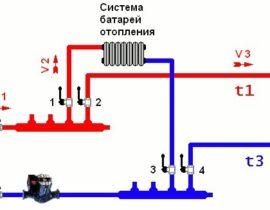

The appearance of mud deposits in the system is associated with the following phenomena:

- Make-up of the system with untreated water from the water supply network. It contains metal salts, which, when heated, settle on internal surfaces.

- Use of antifreeze poured into the system for longer than the recommended time. Data liquids have a limited shelf life. When it is exceeded, the substances begin to decompose and form solid sedimentary fractions.

- Exceeding the maximum allowable heating temperature in the case of using antifreeze. Too high a temperature leads to the loss of the physicochemical properties of the liquid, and, as in the previous case, an insoluble precipitate forms in it.

- Filling the system with poor quality antifreeze or untreated tap water.

- Destruction of the material from which the pipeline is made. Most often, this situation develops when installing heating from galvanized or low-grade steel.

- Breeding of bacteria in the case of operation of the system without draining for the summer or with low-temperature operation during the heating season.

Signs of a clogged heating system

It is almost impossible to completely eliminate clogging of the house heating system. Even if perfectly clean water is poured into the pipes and the heat exchanger, there is no guarantee that scale and rust will not form inside the system, the particles of which gradually cake and form congestion.

- hot eyeliner and barely warm, and sometimes completely cold radiators;

- low temperature in the apartment when the CO is operating in the optimal mode;

- extraneous sounds during the circulation of water in the system;

- growth in energy costs:

- too long warm-up of the system;

- intensive filter contamination, which can be detected during routine inspections.

All this indicates that blockages have formed in certain parts of the heating system and the circulation of the coolant is difficult. If you do not take measures to clean it, the problem may worsen, up to the complete failure of the heating system.

Objectives of CO flushing:

- restoration of heat transfer of heating elements;

- acceleration of fluid circulation and heating rate of the system;

- increase in the service life of CO.

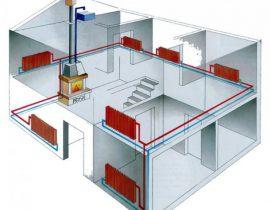

Frequency of the procedure

The more often the system is cleaned, the less scale accumulates in pipes and radiators.

In accordance with regulatory documents, operating services are required to flush the heat supply system in apartment buildings:

- once a year, at the end of the heating season;

- after the overhaul of the heating wiring.

These terms and conditions can also be guided by the operation of heating in a private house. If there are no signs of clogging, you can carry out the procedure every 2 years.

Cleaning methods

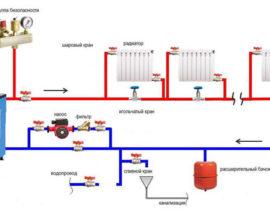

There are several ways to flush pipes and radiators. The choice of the optimal one depends on the availability of equipment, material and structure of the system.

mechanical cleaning

This method requires partial disassembly of the system. You need to remove the expander, water pump and radiators. These parts must be washed separately. The work will require a significant investment of time, but washing in this case will be of high quality and reliable.

The procedure is as follows:

The coolant is drained from the system.

The coolant is drained from the system.- They remove the radiators and take them out into the street. It is better to clean them in the old way with a cable that is driven inside. After working with a cable, the debris is washed out with a bay of clean water using a hose. It is worth noting that for cast iron batteries with their many bends, this method is not entirely effective.

- Straight and curved sections of pipes are also cleaned with a cable, and then washed with water.

- The system is then assembled.

Hydropercussion cleaning

Water hammer technology is used mainly for washing old networks made of cast iron pipes and radiators. This requires special equipmentproviding the required pressure.

The process consists of the following steps:

- The system is completely drained of water.

- Allocate areas in which blockages are presumably formed. In these places, pieces of pipes are dismantled.

- A hose with a special nozzle is introduced into the line. A jet of water is fed through it under pressure. The duration of the procedure is approximately 50 - 60 minutes. During this time, all deposits inside the channels are broken.

- Completes the procedure by flushing the system with clean water. To do this, remove all installed filters from the pipes, fill in water and drain it completely. This helps to rid the pipes of the remnants of plaque.

Chemical cleaning

The method is based on the dissolution of blockages by pouring special chemicals into the system: acids or alkalis. Since salt deposits and pieces of rust are most often the cause of clogging, it is more advisable to use acid-based products.

They cope with such pollution more effectively and quickly than alkalis. The recommended concentration of acid solutions is from 3 to 10%.

They cope with such pollution more effectively and quickly than alkalis. The recommended concentration of acid solutions is from 3 to 10%.

- The cleaning technology with chemicals is quite simple:

- The coolant is completely drained from the system.

- The prepared chemical solution is pumped into the circuit.

- Leave the solution in the system for about a day. Specific terms can be specified on the packaging of the product.

- Drain the cleaning solution and flush the system with clean water with the addition of a neutralizer by connecting the hose to the inlet and directing the drain hose to the sewer.

Flushing the system with chemicals will be faster if the solution is heated to the temperatures recommended by the reagent manufacturers.

Top - 10 best chemicals for flushing the heating system

Modern manufacturers offer consumers a wide selection of preparations for cleaning the heating system.It is necessary to choose a tool taking into account the material of pipes and radiators.

The type of coolant is also important - water or antifreeze. For systems filled with "anti-freeze" is characterized by the deposition of sludge and glycol residues formed during the decomposition of the coolant. Other substances are used to dissolve them.

Ideally, before flushing the circuit, it is recommended to analyze the composition of the coolant, and, depending on the substances contained in the circulating medium, select the agent. But at home, no one will burden themselves with unnecessary difficulties.

Therefore, the masters use a tool that I trust more. First you need to study the recommendations of the manufacturer of the drug on the package. According to consumer reviews, the following brands demonstrate the greatest efficiency.

DIXIS LUX

A concentrate that must be diluted with water in a ratio of 1X9. Suitable for ferrous metal, stainless steel and copper.

Benefits of the tool:

- affordable price (from 1500 to 2500 rubles / 10 l);

- the kit comes with a neutralizer;

- the waste liquid can be safely drained into the sewer;

- quick impact - 2.5 - 3 hours.

To the disadvantages:

- we can attribute the need to heat the solution to a temperature of + 60 - + 70 degrees.

ARGUS SUPER POWER

Concentrate containing an anti-corrosion inhibitor. The working temperature of the solution is +30 - +40 degrees.

Benefits of the tool:

- low cost;

- the presence of corrosion inhibitors;

- low operating temperature.

Disadvantages of the tool:

- bad smell;

- there is no information about the possibility of draining into the sewer.

G63

The drug is in the form of a powder. Compatible with cast iron, all kinds of metals. Contains a rust indicator. The concentration of the working solution is 25 - 100 g / l of water. The working temperature of the solution is + 30 - t + 40 degrees. The cleaning time of the system is 45 minutes.The disadvantage of the drug is the high cost.

TELAKKA HEAT

Flushing agent for systems with plastic or rubber tubes. Does not have a destructive effect on rubber seals. The temperature for using the solution is + 20 - + 35 degrees.

The advantages of the drug:

- the presence of anti-corrosion components;

- does not contain mercury, chlorine, other substances harmful to the environment;

- works at low temperatures;

- has no smell.

To the disadvantages:

- means include the impossibility of application for metal products and high cost.

SYNTILOR Watesup

Professional multi-purpose product: flushing systems made of plastic, metal, rubber. After testing, it is possible to use stainless steel for cleaning. To prepare a working solution, 1 liter of the drug is diluted in 10-15 liters of water.

The advantages of the drug:

- soft impact on materials;

- lack of smell;

- metal protection from oxidation.

Minuses:

- high price;

- unsuitable for alloys with aluminum.

SYNTILOR Watesup All

Preparation for aluminum pipes. Does not destroy rubber and plastic seals.

Benefits of the tool:

- suitability for all grades of steel, including stainless steel;

- efficiency at temperatures from + 20 degrees;

- lack of smell;

- does not contain heavy metals and mercury.

The drug has no drawbacks.

SteelTEX ZINC

Powder preparation compatible with all types of metal. The concentration of the working solution is 10 - 15%. It contains an indicator of residual acidity. Manufacturers recommend using a product with the same brand of acid neutralizer.

Advantages of drugs:

- the possibility of draining into the sewer;

- the presence of anti-corrosion additives;

- Compatible with all metal surfaces.

The drug has no drawbacks.

GEB G30 Desembuant

Ready mortar for metal and plastic systems. 1 liter of product is designed for 100 liters of coolant.

The advantages of the drug:

- the possibility of using for underfloor heating systems;

- small expense;

- compatibility with all materials.

HeatGUARDEX Cleaner 808R

Hydrochloric acid agent. Designed to fight deposits over 3 years old. The manufacturer promises that flushing with the drug will extend the life of the heating system by 10 years. 1 liter of the drug is designed for 100 liters of coolant. The advantages of the drug are simplicity combined with maximum efficiency. No deficiencies found

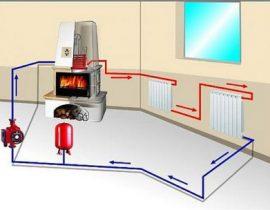

Flushing the heating system with biological products

The most gentle method of cleaning pipes and radiators is to add biological preparations to the system. Substances do not require draining the coolant, quickly dissolve in it and circulate through the pipes for some time, dissolving the deposits accumulated in them.

For preventive flushing, the following substances are added to the system:

These funds neutralize themselves over time, are safe for pipes and radiators made of any material. The advantages of the technique are high efficiency and no need to turn off the system.

How to Reduce the Risk of System Contamination

To keep the heating system working, it is important to observe the following recommendations:

- Carry out flushing at least 1 time in 1 - 2 years.

- Refuse to fill the system with untreated water and low-quality antifreeze;

- Install coarse filters on the main pipelines. Clean them and, if necessary, replace them 1-2 times a year.

FAQ

For complex systems, chemical or biological cleaning is advisable. Water hammer is not effective in areas with a large number of bends. In addition, under high pressure, the destruction of the system can occur. This method is also not suitable if the total length of the pipes in the house exceeds 60 m.

A system filled with clean, filtered water can be cleaned every 3 to 4 years.

Flushing the heating system is a simple undertaking. Even without assistants, it is quite possible to meet in one working day. Therefore, do not neglect this procedure at least once every 2 years. The result will be trouble-free maintenance of a comfortable temperature in the house and significant savings on energy resources.

Video tips for flushing heating systems