A cassette-type fireplace is a type of fireplace structure in which the firebox is located in a “cassette” that is inserted into the main building. This cassette can be a ready-made magazine insert or a homemade one. The cassette fireplace has a closable firebox with a glass door. Despite its size, it is fully functional, the combustion process is carried out on firewood, which significantly distinguishes this type of fireplace from false and bio-fireplaces. Therefore, it is suitable for installation both in a residential and country house and can be installed both in the corners and in the middle of the room, depending on the design of your heating system.

The cassette fireplace has a number of significant features, in comparison with the classic models:

Sample cassette fireplace

- it is light;

- takes up less space;

- has complete autonomy;

- it is possible to control the combustion process: you can influence the intensity of air mass supply to the furnace and the amount of firewood consumed;

- it is also significantly safer than a fireplace with live fire, since the "cassette" is equipped with a transparent fire-resistant glass-ceramic door. This barrier is able to withstand up to 800 degrees of heat, while maintaining the ability to pass radiant heat.

- firewood burns longer, and the resulting heat can be used to heat the room (up to 60% of useful energy).

Despite the fact that the glass-ceramic door requires special care and handling, it is aesthetically pleasing and pleasant to use, because the cassettes have a special system against glass contamination: blowing hot air on the door prevents soot from settling. Thanks to the heat-resistant glass barrier, the risk of sparks on the floor is eliminated, and you don’t have to worry about whether all the coals have gone out in your fireplace: with the door closed, they can smolder for as long as you like.

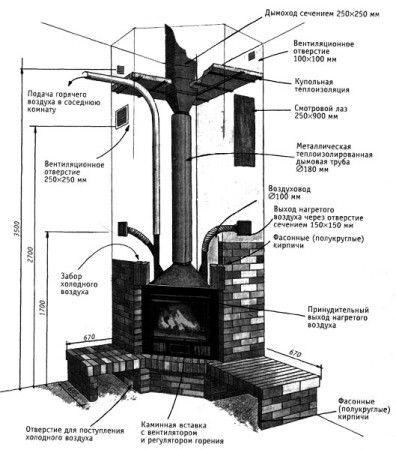

It is not difficult to build a cassette fireplace with your own hands, the main thing is to stock up on a construction scheme, a suitable “cassette” in advance and think over the protection of surrounding surfaces from fire. Fireplaces are most often made of refractory bricks and tiled. Cassette fireplaces are also made of steel or cast iron, with fireclay lining, steel with cast iron lining. Consider an example of building a fireplace with a ready-made mobile cassette and lightweight cladding, in an existing interior. If a built-in firebox is provided, this means that you do not need to think about the combustion chamber, gas baffles and radiant energy reflectors, domes, dampers, chimney - all this is included in the cassette kit. Therefore, lightweight lining of fireplaces of this type is allowed. The basis of the front of the fireplace is a frame made of metal corners or reinforcement bars. And blocks or other building materials are mounted to the frame.

Content

Video: Cassette fireplace in a drywall niche

How to start building a cassette fireplace

If the house already has a major chimney, there is no doubt about where to place the fireplace. At the chimney, preparation of all surfaces to which the fireplace will adjoin is carried out.

- Even a cassette fireplace requires a project. It is best to plan the location of the heat source at the stage of building a house. And if the construction is going on in the finished space, you need to pay attention to the safety of the structure by drawing up a general scheme for installing the fireplace.

- After determining the installation site, you need to make a base for the fireplace. To do this, a layer of insulation (or thermal insulation) is laid directly on the floor. A reinforced concrete screed is made on it under the pedestal of the fireplace. Screed thickness up to 15 mm. The light weight of the future structure allows you not to break the finished floor in order to strengthen the base of the fireplace.

- For the construction of the pedestal, it is convenient to use aerated concrete blocks. Give them the shape and the necessary dimensional parameters with a rasp or a hacksaw. Subsequently, this durable material can be plastered or revetted.

- For laying aerated concrete blocks, you will need a mortar or glue. Laying is done in the usual way. But keep in mind that the portal threshold will need to be issued immediately. Let's say natural stone. The stone plinth is glued to the pedestal using heat-resistant glue or fixing the material with dowels and screws. When creating the basis for the "stuffing" of the fireplace, we must not forget about the technical holes for the subsequent maintenance of the fireplace. The ventilation and viewing manholes of the fireplace after finishing work are closed with decorative grilles.

- After completing the masonry, you need to level the top wall of the pedestal. To do this, it is plastered with cement mortar, 10-15 mm layer.Be sure to use a layer of asbestos cardboard and iron for thermal insulation. It is placed under the cassette slot.

- Accurately calculate the place of installation of the fireplace cassette in the finished pedestal: it is necessary to plan a sufficient amount of space for the heating system, calculate it so that the metal hose-chimney can be conveniently connected to the part of this system in the cassette. If the cassette-firebox is mounted in an existing fireplace, the main thing is to tightly connect it to the chimney. The mobile fireplace cassette is installed on a finished pedestal. It is better to first place it on the bars and then remove them one by one, making sure that the cassette fits securely and clearly into the prepared niche.

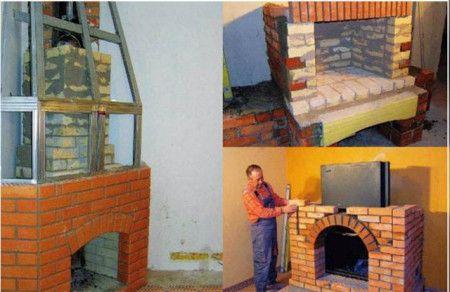

Cassette fireplace frame and cladding

We proceed to facing the base and the shelf of the hearth. When using aerated concrete blocks, steel corners are needed around the perimeter of the structure, which will be the frame of the structure. They are welded on the outer corner.

- To decorate the mantelpiece, you can use marble, which is laid on heat-resistant glue. Allow the glue to dry properly. To prevent the plates from shifting during drying, they are pulled together with clamps to the fireplace base.

- The duralumin or profile frame will easily hold the plasterboard sheathing, which is fixed with metal screws (19-25 mm).

- In addition to the skin, you will need to attach a protective glass for the cassette to the frame.

- After the glass, heat-insulating mats are also attached to the frame, one side of which should be foil-coated.

- If you want to arrange a place for storing firewood, you need to attach brackets to the frame, on which a shelf for storing fuel will be installed. She also gets off with heat-insulating mats.

- The frame is lined with any decorative material: tiles, tiles, natural or artificial stone. Be sure to use hot glue so that the fireplace serves you for many years.