The special charm of the fireplace is given by its cladding. The outer part of the fireplace, which is a fundamental part of the entire stylistic design of the building, is called the portal.

If you are not deprived of a creative vein - make a portal for the fireplace with your own hands, it will not only cost you very cheap, but also raise your self-esteem, you could do it yourself!

Most often, when creating decorative portals for a fireplace, the following materials are used:

- natural and artificial stones (dolomite, granite, travertine, marble, brick and others);

- wood (decorative details with carvings), drywall;

- metal elements (cast and forged);

- various combinations of synthetic materials.

Content

How to choose the right design for the fireplace portal?

In order to correctly answer this question, you must meet the following requirements:

- The design styles of the fireplace and the portal must be consistent.

- The proportions of the portal should be carefully selected in relation to the volume of the room and the height of the ceiling. In this case, the possibility of placing a TV above the mantelpiece is necessarily taken into account.

- The fireplace should not stand out from the overall interior design.

- It is customary to purchase an electric fireplace before a portal is designed for it.

- Materials for the manufacture of the portal must be safe, durable and strong enough.

Brick fireplace portal

The facing brick portal may not be connected to the main masonry. Decorative brickwork with jointing looks very aesthetically pleasing and attractive. But bricks should be selected very carefully, paying attention to all chips, cracks, edges, size and color (the color range, textures and types of facing bricks are quite wide). The seams between the bricks should also be as accurate as possible, contain reinforcing additives and high-quality coloring pigments.

In order for the masonry to be as even as possible, a narrow wooden lath is used in vertical and horizontal seams. Laths are laid between layers of bricks so that they do not come into contact with the mortar. Each brick is tapped with a hammer, achieving perfectly even seams.

The laying of the floor can be horizontal, in the form of an arch, wedge, radial, have small protrusions or without them.

Stages of building a brick portal:

- We design a drawing of the portal. On paper in a cage, we create a sketch (3D image of the portal), drawings with horizontal sections (ordering).

- We prepare a solution. We prepare clay, sand and cement. The ratio of dry parts of cement and sand is 1 to 8. Sift the sand through a sieve with small cells, mix with cement. We soak the clay in water, dissolving it to a homogeneous consistency of thick sour cream. We mix the clay into the dry cement-sand mixture.

- Construction.

arch masonry

Arches are straight, arched, semicircular (in half a circle).

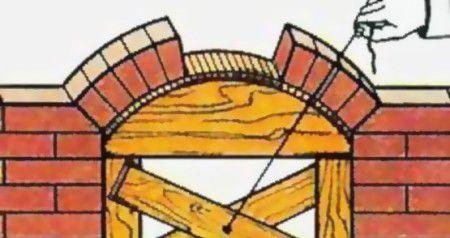

- Cooking circles: cut out two semicircles from plywood, the radius of which is equal to half the width of the firebox.We connect the parts with wooden bars (nailing the bars and plywood with nails) each 11 cm long.

- We make a marking of a wedge of bricks. To do this, we put the circle on a flat surface, fix the thread in the center, lay out the bricks around the circle and draw them (cut lines from the upper corner to the base). We grind the excess with a grinder.

- We install the circle in the furnace using props. We check the correctness of the lines with a level and a plumb line.

- We start laying bricks from one of the edges. We check the correctness with a thread stretched from the center of the circle.

Bow arch (used for fireplaces with a rectangular firebox or if the height of the woodcutter's portal is limited):

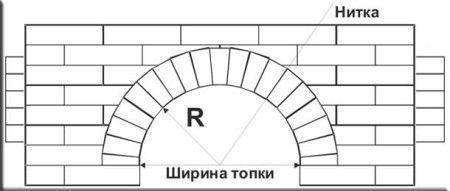

We calculate the radius of the arch.

R=(B2 + C2)/2B

R is the radius of curvature of the arch;

B - the height of the arch (standardly it is taken by 1-2 rows of brickwork);

C - ½ the width of the firebox.

When the radius of the arch is calculated, we mark and cut the plywood, collect the circle and install it on supports. The brick laying technology is similar to the laying of a semicircular arch.

straight arch:

For such an arch, there is no need to cut a circle. Instead, they use a board. The principle of a straight arch - construction is made from bricks ground off in the form of a wedge.

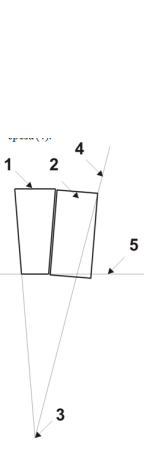

- We find and mark the center of the arch, fix the thread.

- We install a brick in the center of the board, which will be central.

- With the help of a thread stretched from the center to the corners of the brick, we find the cut lines, mark them. We cut the brick strictly along the lines.

- We attach the next brick (2) to the central one (1) so that their lower corners coincide. We pull the thread to the upper corner of the second brick. Mark the cut line (4).

- The next cut line (5) is drawn along the board.

- Next, the bricks are marked and cut in the same way, until you get a set of bricks for laying out an arch with a flat bottom and a top in the form of steps.

- The laying is carried out along the board used instead of the circle.

Portal for electric fireplace made of drywall

In order to make a beautiful drywall portal, you need to follow all your steps clearly according to this list:

- We purchase an electric fireplace, measure its dimensions.

- We determine the place where the future fireplace will be located.

- We make a drawing with images of the frame and the appearance of the fireplace.

- We make markings on the walls, on the floor.

- According to the drawing (dimensions), we cut the metal U-shaped profile (UD or CD) into parts and assemble the frame on self-tapping screws, starting from the support frame near the wall.

- We check the correctness of the lines with a building level and a tape measure (diagonal).

- We mark and cut sheets of drywall and fasten them with screws to the finished frame in two layers.

- In a similar way, we assemble the foot of the future fireplace portal and a mantelpiece from drywall and a metal profile.

- We fix the mantelpiece and the foot with self-tapping screws and glue (or silicone).

- In two or three layers, we putty all joints and holes, smooth out irregularities with an abrasive mesh until absolutely smooth surfaces are obtained.

- We putty the surface and proceed to decorate the portal using self-adhesive film, paint, gypsum stucco elements, decorative plaster or other materials necessary to create a stylistic design for the fireplace portal.

Finishing the portal for the fireplace with artificial stone

Artificial stones have a number of advantages. The appearance can imitate granite, malachite, sandstone, marble and other natural stones.Artificial stones are divided into three groups: porcelain stoneware, agglomerates and stones from colored concrete.

Before purchasing material for the construction of a fireplace portal, you should pay attention to:

- the thickness of the purchased stones (this affects the dimensions of the finished structure);

- frost resistance and percentage of water absorption;

- repeatability of elements (optimally 3 m2).

Stages of preparation:

- We create a sketch of the future portal with the drawing of all elements and taking into account the color scheme.

- Open several packages and mix them. We clean the side of the stone that will be in contact with the adhesive mixture and the wall with a metal brush.

- Using a brush or roller, apply an acrylic primer to the cleaned surface of the stones.

Laying:

- We lay out the drawing on the floor according to the sketch (for trimming, we use a grinder with a cutting wheel).

- We moisten the surface of the fireplace and stones with a brush.

- We start laying from the top corner, initially using whole elements and taking into account the thickness of the seams. In the rows, larger stones alternate with smaller ones. Accordingly, for the upper rows, elements of a smaller thickness are chosen, and for the lower rows, a larger one.

- We carry the adhesive solution and level it with a spatula. We maintain a layer of about five millimeters.

- We press the stone to the surface and slightly scroll in different directions.

If necessary, we produce jointing and apply paint and a protective coating to the front of the masonry.