A malfunction of gas equipment in modern boilers is encoded with certain numerical and alphabetic values. Such codes allow you to determine exactly what the problem is and quickly fix it. Proterm gas boilers differ in the type of ignition, installation method and the number of circuits.

But malfunctions in the form of codes have a common decoding. The technical operation manual often indicates possible problems for a particular boiler model. Consider the most common mistakes, their causes and ways to eliminate without calling experts.

Content

- Important Rules and Precautions

- The most common errors, decryption and solutions

- F0 - critically low pressure in the circuit

- F1 - no flame in the burner

- F2 - temperature decrease to critical values

- F3 - boiler overheating

- F6 - actuation of the reverse thrust sensor

- F7 - disconnect

- F10-F19 - a group of errors in the event of a short circuit of the circuits

- F24 - Rapid rise in temperature

- F-25 - ventilation problems

- F-28 - flame extinction when turned on

- F-29 - flame extinction during boiler operation

- How to Avoid Errors: General Tips and Tricks

- Video tips for correcting errors on Proterm boilers

Important Rules and Precautions

It's no secret that using faulty gas equipment is life threatening.At any moment, a banal mistake that could be eliminated by a specialist in 15-20 minutes can become fatal and provoke an explosion.

Therefore, before proceeding with repair work, remember and never violate the following rules:

- Not all errors can be fixed on your own - some of them indicate system breakdowns, for the elimination of which only a specialist is needed. Opening the boiler and making repairs without permission to carry out these manipulations and without experience is fraught with negative consequences.

It is strictly forbidden to open the internal parts of the boiler - schemes on the Internet, tips from locksmiths or neighbors will not help if a person does not have the appropriate skill. So you can damage expensive parts, the replacement of which will cost more than one thousand rubles.

It is strictly forbidden to open the internal parts of the boiler - schemes on the Internet, tips from locksmiths or neighbors will not help if a person does not have the appropriate skill. So you can damage expensive parts, the replacement of which will cost more than one thousand rubles.- Do not use faulty gas equipment - some craftsmen bypass all prohibitions by resetting the system, forcing the boilers to work bypassing the control of the central board. This leads to rapid wear of individual parts, as well as a high explosion and fire hazard.

- If all measures aimed at eliminating the error (the simplest) did not give a result and the boiler is still not functioning, you should call the masters, and not engage in self-repair.

The miser always pays twice, so trust the repair of your own equipment only to companies specializing in such work. They will issue the appropriate document, as well as make repairs, taking into account the features of the breakdown. It is one thing to add water to the system, and another to replace the board or the internal pump.

In order for the boiler to break down less often (and this often happens in winter, during the period of its active use), before the start of the heating season, a preventive start-up should be carried out by calling specialists.

They will evaluate the operation of gas equipment, perform scheduled cleaning of the heating element from scale, and also give advice on how to properly use the boiler in the future. Prevention is always better than replacing broken expensive parts.

The most common errors, decryption and solutions

Modern Proterm boilers are equipped with automation that works and stops the operation of the equipment in case of malfunction of individual components. The central board regulates all processes, which makes hints to the user in the form of codes. Their decoding will help to understand what exactly is the reason for the forced stoppage of work and how to fix it.

F0 - critically low pressure in the circuit

The emergency stop of the boiler is associated with a sharp drop in pressure in the heating system to critical values \u200b\u200b(0.65 bar).

The following reasons can provoke this:

- Water leakage from the system - they forgot to close the tap on the pipe through which water was supplied to the heating circuit. The system took as much as it needed, after which the water in the water supply was turned off, respectively, the water from the circuit could simply go into the general water supply. The problem is relevant if there is no expansion tank and water is supplied to the circuit directly from a common water supply.

Evaporation of water from the expansion tank or leakage from it - it happens when people forget to add the required water level, or the expansion tank has a pronounced leak.

Evaporation of water from the expansion tank or leakage from it - it happens when people forget to add the required water level, or the expansion tank has a pronounced leak.- Incorrect operation of the flow sensor, which causes the formation of a false signal about a pressure drop in the system.Often caused by blockages in small cells.

- Malfunctions in the electronic board, which erroneously generates a low pressure signal, which leads to an emergency shutdown of the boiler.

In Proterm boilers, the F0 error often appears precisely when the board malfunctions, namely the presence of condensate on the surface, which closes the contact paths on the board itself. Outwardly, it manifests itself in the form of cliffs and blackouts of individual sections. The installation of gas equipment in an unheated room at low temperatures provokes the development of condensate.

What can be done to resolve this error without calling the wizards:

- Walk around the entire heating circuit in search of water leaks. Particular attention should be paid to the joints, especially if they are not soldered, but twisted. In the presence of damage to the pipes, the system is turned off, the water is drained, repairs are made, and then the heating is restarted.

- Inspect the expansion tank for leaks or check the tap for supplying water from the general water supply to the heating circuit. Often the problem lies precisely in the tap, which eventually leaks, visually assessing the presence of which is almost impossible. Replacing the gasket or replacing the entire faucet in 95% of cases solves the problem of code F0.

- Check the bottom of the boiler for condensation or moisture.

All other actions to open the boiler and assess the health status of the boards and individual parts can only be performed by the masters.

If the problem has been fixed and the boiler does not give an error after restarting, be sure to check your batteries for air. Walk through each and deflate until water appears.

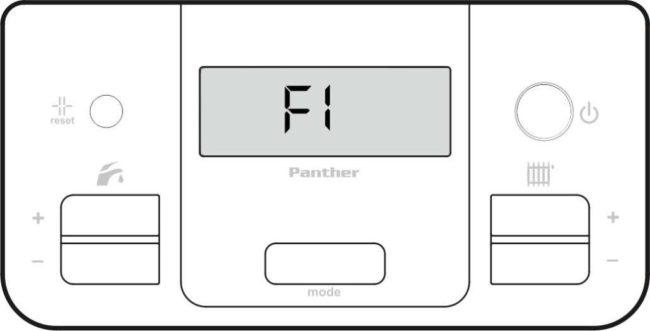

F1 - no flame in the burner

Proterm boiler owners often complain about ignition problems when all actions are performed according to the scheme, but it does not occur. The reverse side of the coin is when the boiler can be ignited, but it spontaneously goes out, giving an F1 error on the display.

The absence of a flame in the burner can be caused by a number of such reasons that have nothing to do with the breakdown:

- Power outage in the house - there is no spark that could ignite the gas in the burner.

- The gas supply valve is closed - there is a spark, but there is essentially nothing to set fire to.

- Operation of the shut-off valve during a power outage, which generates an error and blocks the operation of the boiler.

- Contaminated pipes, plugs, valves for summer storage, which prevent the outflow of gas from the burner.

The absence of a flame and the corresponding error in the Proterm boiler are also possible for such reasons, indicating a breakdown and the need for repair:

- Emergency thermostat operation when the temperature in the circuit is higher than the values allowed by the manufacturer. The boiler will start automatically as soon as the temperature is lowered. Why such a failure occurred - there are a lot of reasons. Particular attention is paid to assessing the state of the thermostat. It often crashes.

- Problems with the ionization sensor, which gives a false signal that there is no flame, although in fact there is one. A common cause is carbon deposits on the electrode itself, which leads to the formation of cracks and creases.

- Lack of contact of the ionization sensor with the burner. The recommended distance is no more than 5-7 mm, but when cleaning it can be increased up to 10 mm. It is necessary to correct the end of the wire to the burner and the problem will disappear.

- Pollution of the nozzles with soot and dust, which interferes with adequate operation and ignition of the boiler.

- Failure of parameters in the boiler control system - is removed by rebooting and restarting the boiler. It happens during sudden power surges in the network, which causes an emergency stop of the Proterm boiler.

- Malfunctions in the electronic board, including the formation of condensate and small circuits. Along with the F1 error, others appear that indicate the need for a complete diagnosis and repair.

The maximum that can be done without repairmen is to check the gas supply and connect the boiler to the network. The rest of the work is carried out only by professionals.

It is not recommended to open the boiler yourself and climb into the nozzle. Wrong actions can harm and entail a lot of additional and unnecessary costs.

F2 - temperature decrease to critical values

This error occurs in two cases:

- The coolant temperature has dropped to +3°C, which is fraught with the formation of ice, so the boiler turns off automatically.

- The temperature is estimated inadequately, a conflict arises.

The problem is the temperature sensor, which is out of order. The reasons for its breakdowns can be frequent power surges in the mains, or contact closure. If there is such an error, the sensor is dismantled and checked for faults. In most cases, it needs to be replaced with a new one.

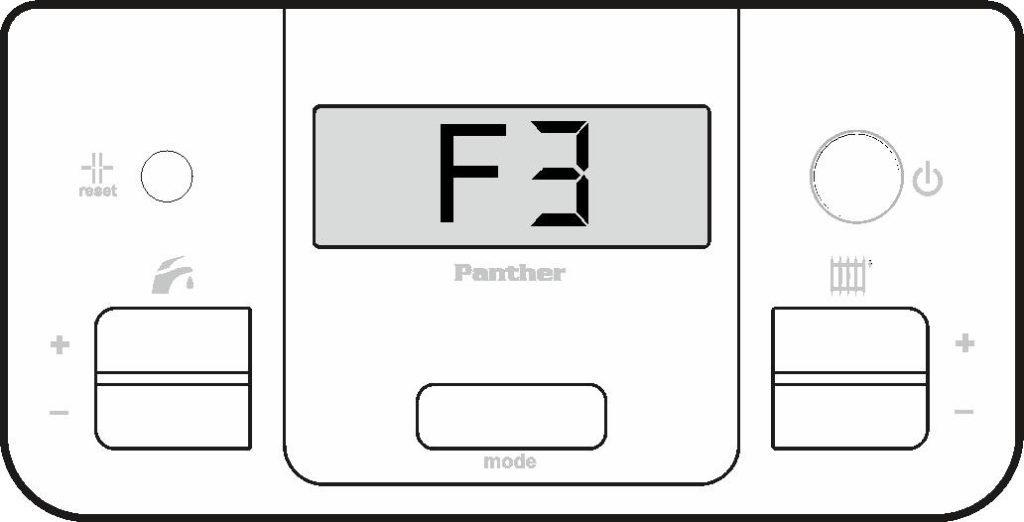

F3 - boiler overheating

The error occurs when the allowable boiler temperature is exceeded. An automatic shutdown is activated to protect equipment and ensure the safety of people.

The reasons for the high critically high temperature values \u200b\u200bof the Proterm boiler can be:

- Scale in the heat exchanger, which accumulates in the absence of preventive cleaning. The cause of scale is also hard water.

- Transport plug, which is installed at the factory in order to prevent dust, debris and dirt from entering the boiler. During installation, it must be removed, otherwise it will provoke overheating due to blocking the circulation channel.

- Filter contamination - a filter is installed in the area from the return connection to the pump, which clogs over time, protecting the heat exchanger and the internal circuit from the ingress of suspended particles from the heating system.

- Lack of pump performance - heating occurs inside the boiler, but water is not distributed throughout the system, which provokes overheating of the unit and an emergency shutdown. The pump should be inspected and the reason for stopping its operation should be determined. Often these are internal impurities that are easily removed with a napkin.

You can only determine malfunctions in the operation of the pump on your own. To do this, listen to him. A working device makes a characteristic sound of pumping liquid, which is accompanied by a slight vibration. If we are talking about single-circuit boilers, in which the pump is placed outside the design of the heater itself, then it is important to make sure that the pump is connected to the network. The rest of the work is done by specialists.

F6 - actuation of the reverse thrust sensor

F6 - actuation of the reverse thrust sensor

Indicates a breakdown of the sensor that controls the exhaust gases. Often the reason is a violation of the integrity of the contact between the board and the sensor (damage to the wire).

Diagnostics is needed not only for the sensor, but also for the board. Sometimes the reason lies precisely in it. You should also pay attention to the ignition transformer. Its malfunction distorts the operation of the sensor.

F7 - disconnect

One of the most insidious mistakes that repairmen do not like so much.It means that somewhere there was a break in the connection between the connecting elements of the equipment. And where exactly - you have to search manually, sorting out individual parts and groups of contacts.

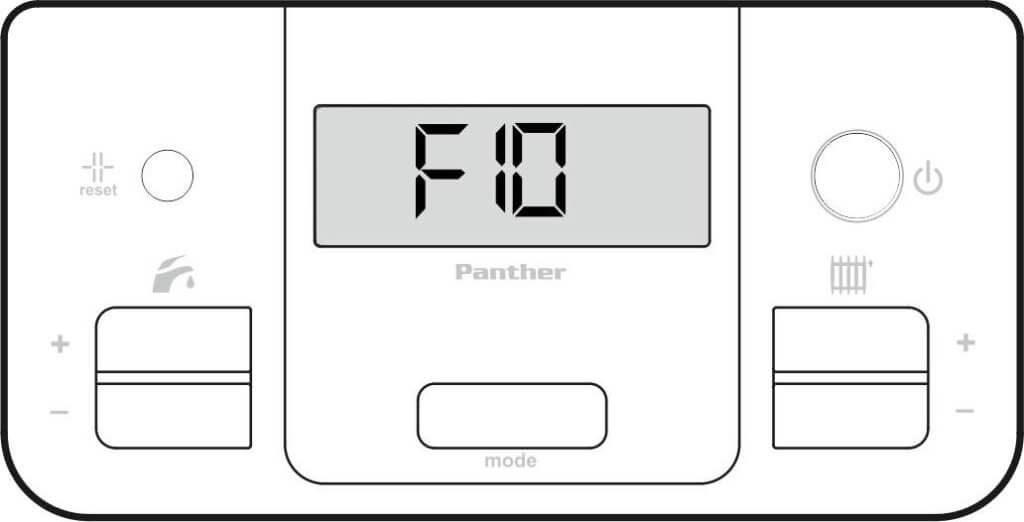

F10-F19 - a group of errors in the event of a short circuit of the circuits

Errors in this range indicate short circuits and malfunctions of individual elements, which ones, the code will tell you:

- F10 – temperature at the outlet of the heat exchanger;

- F11 – inlet temperature;

- F12.13 - temperature of hot water when connecting the boiler;

- F14.17 – when connecting a solar collector;

- F15 – flue sensor;

- F16 - pressure switch;

- F18 – ground control sensor;

- F19 - exhaust sensor.

F24 - Rapid rise in temperature

The problem is to reduce the amount of coolant and the rapid increase in temperature in the system, which can be caused by such reasons:

- H

malfunction of the pump that does not pump water through the system: pollution, breakdown, jamming of the main mechanism, lack of connection to the network.

malfunction of the pump that does not pump water through the system: pollution, breakdown, jamming of the main mechanism, lack of connection to the network. - Airing the heating system when there is air in the batteries that heats up faster than water. You need to go through each battery and lower it until a trickle of water without bubbles appears.

- Water left the system due to an open supply valve or a leak. It is necessary to check all twists and solderings, as well as batteries and taps for leaks.

If the temperature rises very quickly, the security system is automatically triggered, which blocks the operation of the boiler. Restart is possible only when it is reduced by a few degrees. The sequence of actions is the same as for the F0 problem.

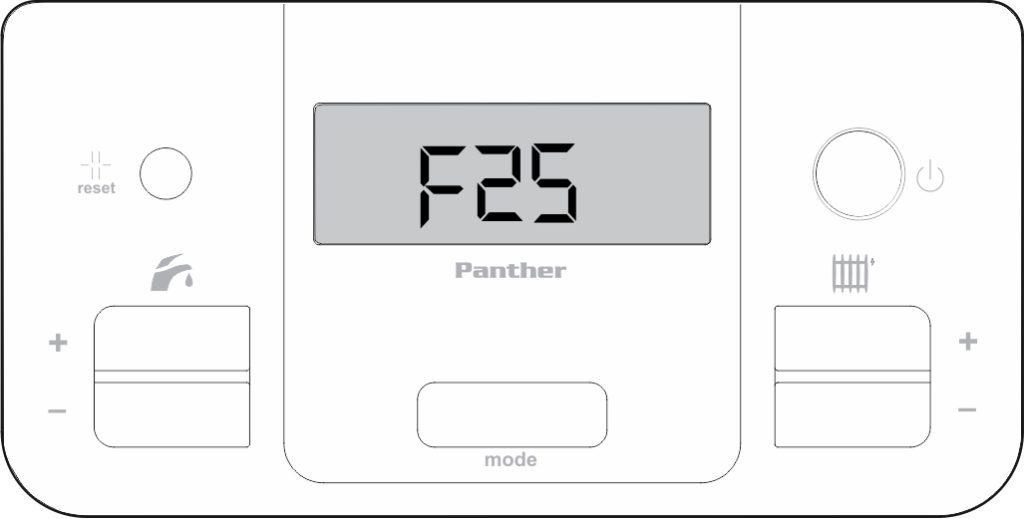

F-25 - ventilation problems

If a high percentage of carbon monoxide is detected in the boiler, an automatic sensor is activated, which opens the contacts of the ryle, stopping the operation of the boiler.

The following reasons can provoke such a scenario:

- Depressurization of the walls of the chimney, cracks and gaps appeared in the joints.

- Faulty thermostat, which fixes false values.

- Failure of the fan, which prevents the exhaust gas from escaping outside the living space.

- There is no draft, especially if the outlet pipe was covered with paper or rags for the summer.

- Control board failure.

It is necessary to check the ventilation for draft, as well as the contamination of the pipe itself. The rest of the diagnostic work is performed only by the master.

F-28 - flame extinction when turned on

When ignited, a flame wick is formed, which goes out within the first minute.

When ignited, a flame wick is formed, which goes out within the first minute.

The following reasons cause this problem:

- Low gas pressure or the valve is not fully open (or closed at all).

- The ionization electrode is contaminated with soot, which must be cleaned periodically.

- Problems with the electronic board with frequent power surges in the network.

In such a situation, it is better to contact a specialist who will audit the entire firing group and clean it, which will help eliminate this error.

F-29 - flame extinction during boiler operation

There are two typical reasons for this:

- Stopping the gas supply in the system - the operation of the boiler is blocked, as an emergency shutdown signal is generated on the board.

- Malfunctions in the board itself - gives false signals due to damage or short circuits.

Only a specialist should deal with the problem.

How to Avoid Errors: General Tips and Tricks

It is always easier to prevent than to deal with the consequences. Remember these nuances:

- Work with gas equipment should be trusted only to professionals who give a guarantee.

- Defective parts should only be replaced with original parts. If spare parts from other boilers are installed (second-hand is especially dangerous), no one can guarantee the safety of such equipment.

- Annual preventive maintenance boiler cleaning. There are special companies that provide these services in full.

- Don't forget to check the exhaust. Sometimes it can get clogged.

- Do not allow the temperature in the room where the boiler is located to fall below 3°C.

- Check the water level in the system, paying attention to the pressure. The norms for your boiler are written in the instruction manual.

In conclusion, it is worth noting that Proterm gas boilers in rare cases issue fault codes erroneously. If this happens, then it is necessary to determine the cause and eliminate it. A complete diagnosis can only be made by a specialist, as well as repairs. It is not recommended to open the cover yourself and replace parts, as this may be unsafe for health and life in general.

Video tips for correcting errors on Proterm boilers

does not give an error does not heat the system electric proterm 6kw

My boiler on the scoreboard gives out F 33 and the system stops, what is the reason

Is it possible to remove a subsidy

Good afternoon, most likely the protective mechanism of the fan has worked. You need to contact the repairman for a more accurate diagnosis.