Hot water in an apartment or house has always been integral part of the comfort, without which a modern person cannot imagine his life.

There are frequent cases when hot water in apartments is turned off, and in the private sector the owner generally must take care of himself her availability. Water heaters can help with this. The boiler device for heating water can be very different, but the main distinguishing feature it from flow heaters - the presence of a storage tank in which there is always a supply of heated, ready-to-use water.

Modern storage water heaters can be of direct or indirect action. Direct fired boilers can use either electricity or natural gas as the energy source. In indirect heating systems, heat exchange takes place from the heating system of the house or from other sources of thermal energy (for example, solar water heaters).

Consider various schemes for the device of modern boilers.

Content

Boilers for direct heating

In such systems, the transfer of thermal energy goes directly on onheated water for further domestic use. They can be electric or gas.

Electric direct heating boiler

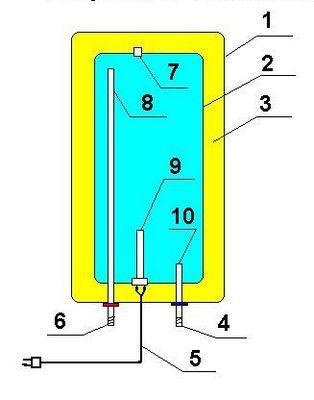

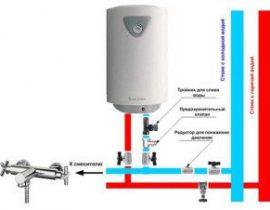

Layout, location, placement input and weekends branch pipes, the control and automation system from manufacturer to manufacturer can vary significantly, but the concept is the same. On the image given her general simplified view:

- The whole structure is assembled in a metal case (1), which has one or another external decorative design. Inside there is a water tank (2), and the space between it and the outer casing is filled with thermal insulation material (3), most often polyurethane foam.

- Cold water is supplied through the intake pipe (4), on which the return valve and a safety valve that operates when excess pressure inside the boiler. The supply pipe (10) is usually equipped with a mesh atomizer to avoid the formation of turbulent water flows.

- Via Power Cord (5) on onheating element — Heating element (9) served alternating current. The device must be equipped with a temperature control system and a thermostat that allows you to set the required level of water heating and automatically turn off the power supply when the required temperature is reached.

- Branch pipe (6) is connected to the hot water supply system — through it, heated water through the tube (8) from the upper part of the boiler enters the points of consumption. The necessary pressure is maintained by a constantly open supply of cold water - it replenishes the tank as it is consumed, and it always remains filled.

- The air valve (7) serves to bleed air when the boiler is initially filled with water - it does not gives form an air cushion.

To prevent galvanic corrosion in the water tank, German have an anode made of magnesium. Its electrical potential is less than that of the tank body or the surface of the heating element, so destructive corrosion processes will affect it. Periodically, as corrosion and overgrowth occur, the anode is replaced with a new one.

Such a scheme is simple, and is the most widespread among household boilers. Such devices are usually inexpensive, which makes them popular with consumers. The main disadvantage is that the heating element works directly in heated running water, which leads to its rather rapid overgrowth with mineral deposits dissolved in it.

Direct fired gas boiler

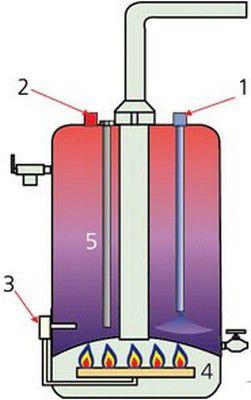

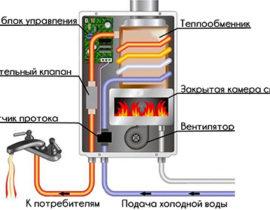

The gas boiler is quite simple in terms of the principle of its operation and has the following general layout:

- In a metal case (most often stainless steel), which has reliable thermal insulation, a water tank is located.

- Through the pipe (1) to the bottom containers served cold water. A branch pipe is welded in the upper part of the tank for the intake of heated water with subsequent her distribution to points of consumption.

- The gas burner is located under the bottom containers (4), her a semicircular panel, which plays the role of a heat exchanger, closes from water.

- The second heat exchanger is a pipe for removing combustion products - it passes through capacity with water. Gases are removed through a conventional chimney or a coaxial type system (depending on the model of the boiler - with an open or closed combustion chamber).

- The magnesium anode (5) serves to collect scale - it must be changed regularly, as it overgrows.

- Boiler required equipped automatic control system - thermostat (3), to monitor the temperature level, a valve to shut off the supply gas upon reaching the set level of water heating, a piezo ignition device - for automatically starting gas burners when the liquid cools down as her consumption.

A gas-fired boiler has a high performance, it is much more economical than an electric one. However, it also has significant drawbacks - it requires a mandatory chimney, and its installation is associated with the process of coordinating the project with the supervisory technical supervision authorities. In addition, such direct heating boilers are much more expensive than electric ones.

Indirect heating boilers

The main thing fundamental difference - heated for domestic needs (so-called, sanitary) water does not have direct contact with electric or gas heating devices. Heat transfer goes per check connection to the house heating system (or other sources of hot boiler water).

Such a boiler is most often installed in combination with a single-circuit heating boiler. This type of boiler may have volume, measured in tens or hundreds of liters, and which one to choose — will depend on the number of households. Floor models are produced, or they are mounted to the wall horizontally or vertically on special brackets.

According to the organization of heat transfer, they can have a completely different layout:

Boiler with spiral heat exchanger

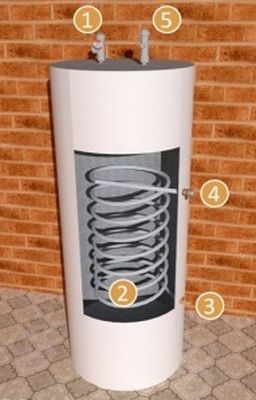

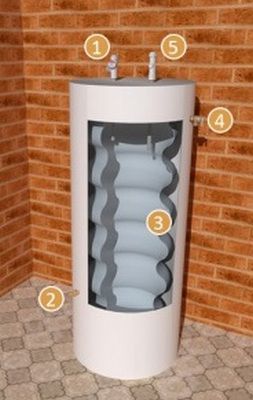

This boiler is designed as follows:

- Inside the thermally insulated housing there is a volumetric tank for sanitary water.A heat exchanger (2) in the form of a coil is installed in its cavity.

- Through nozzles 3 and 4, the coolant is circulated - hot technical water received from a single-circuit boiler. Warm transmitted sanitary water, the flow of which is carried out in the lower part containers through the inlet pipe (1).

- The discharge of heated sanitary water is carried out from top parts of the tank through the pipe (5).

The coil in some models is located closer to the bottom containers, where cold water falls, and in others — evenly distributed throughout the tank, which allows you to quickly heat the entire volume liquids.

Boilers are produced, the design of which includes two heat exchanger tubes. The coolant heated by the boiler passes through one circuit, and through the second — from other possible heat sources, such as solar water heaters.

Scheme "tank in the tank"

Another version of the indirect heating boiler does not have coils with a coolant inside, but is arranged somewhat differently. It consists of two containersthat are installed one inside the other. Naturally, the tank, which is located inside, has a smaller volume - he are accumulator of heated sanitary water.

The diagram clearly shows the internal structure of this model.

- Through pipe 1, cold sanitary water is supplied to the internal tank.

- Branch pipes 2 and 4 are connected to the heating system - boiler hot water circulates through them.

- The inner tank (3) is made of stainless steel.

- Through pipe 5 goes hot water intake for domestic consumption.

Positive qualities of indirect heating boilers:

- Good performance of the device if the heat exchanger has sufficient area and the boiler is connected to a high power boiler.

- Energy savings and no load on the power grid.

- The coolant does not come into contact with sanitary water. Specially prepared water passes through the heat exchanger, which contains a minimum of salts.

- Ability to switch the boiler to different energy sources, for example, in winter it can work from fromheating boiler, and in the summer — from a solar battery.

However, there are also disadvantages:

- When water is heated in the boiler, the temperature in the heating system decreases.

- it — rather expensive equipment, compared with a direct heating boiler.

- The whole complex takes up a lot of space, those. it is better to allocate a separate room for him, which is not always possible.

You can learn more about the device of a boiler for heating indirect water by watching the video attached to the article:

Video - an overview of the capabilities of an indirect heating boiler

Combined action boilers

Boilers that combine both principles are a good option. They are connected to the heating circuit, but their design also implies the presence of their own heating element. For example, a diagram of the SMART heating boiler device from ACV:

- The shock-resistant polypropylene casing (10) contains a steel outer tank (8) made of sheet hoist With reliable polyurethane foam thermal insulation (3). It serves to circulate water from the heating system supplied from the boiler through the pipes (11).

- Inside it placed tank for sanitary water from stainless steel (9).It provides for the inlet of water from the hot water supply (14) and the outlet her to the points of consumption through the tube (2).

- In the upper part there is a cover (7) with a manual air outlet (1) - for the initial filling of the system.

- Inside external tank placed Heating element with power from 2 to 6 kW (5) - it will turn on at the command of the automatic controller if the thermostat (4) detects insufficient heating through the external heat exchange system. In the summer, when the heating system is turned off, the heating element will be the main source of heat energy.

- The control panel is equipped with the necessary adjustment devices - sanitary water heating temperature, on timer heating element (for example, for its use at a reduced night rate).

Such a boiler design is the most versatile, and combines the positive qualities of all the systems mentioned above. Perhaps the only drawback of such a water heater is the rather high price.

When choosing a water heater, consider the pros and cons of each option by looking at the characteristics of each. It is also important to pay attention to the size of the selected device and consider the place that it should take.