Situations in which you can not do without an additional water heater are quite often — it can be a private house or cottage, where there is simply no centralized hot water supply, or in those apartment buildings where his often turned off.

If you are tired of running buckets and saucepans from the kitchen to the bathroom, and there is not enough money to buy a boiler in the store - you can try to make an indirect heating boiler with your own hands. Trust us, this is not such an impossible task!

This boiler is of two types. — heated with a heat carrier from the heating system and wood.

Content

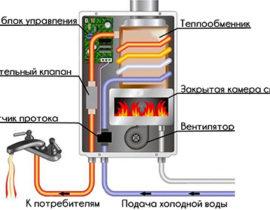

The principle of operation of an indirect heating boiler

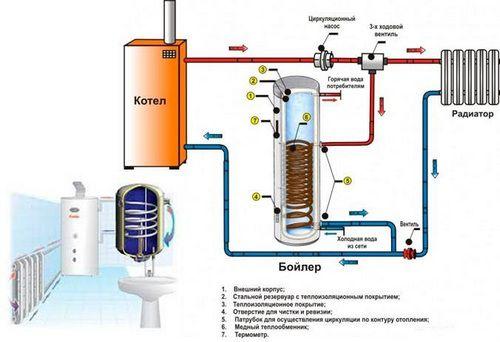

This option is ideal for an apartment building, but it can be used at no extra cost only during the heating season. For the period when the central heating is turned off, in German it is possible to provide electric heating element. In this case have to pay more for electricity, but you can turn on the heating as needed.

The same system can be arranged in a private house, if in German installed independent heating from the boiler.

Construction and materials

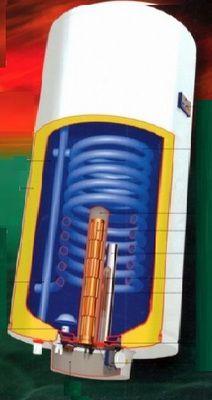

This type of boiler consists of containers, which can have any volume. Her it is better to make it from stainless material, so it will last a longer time, and the heated water will always be clean. For containers boilers usually use a barrel, a new gas cylinder, or do tank to order.

- In the middle containers a pipe is installed, twisted in the form of a coil, and the coolant will circulate through it. It is good to use copper or brass as a pipe - metals with good heat dissipation. However, as an option, it is possible to choose a metal-plastic pipe of small diameter for this purpose.

- To make a neat coil, a long tube (about 15 meters) is wound to another a pipe of a larger diameter, on a wooden even log or another suitable cylindrical object.

- The number of turns on the coil depends on the shape and height containers, but the longer the pipe twisted into a coil, the faster you can will be receive HEATED WATER.

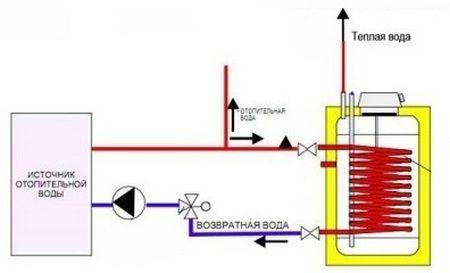

- The ends of the pipe are removed from the tank in different places. Above containers have a branch pipe into which the coolant from the heating system will enter. After passing through the coil, it returns to the heating circuit through another branch pipe located at the bottom of the tank.

- Two holes are arranged in the tank: for filling it with cold water and for taking heated water. The first is arranged from the bottom of the tank, and the second from above, from where hot water is diluted to the right points: a shower or kitchen tap.

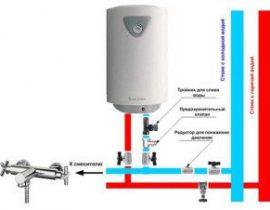

On the diagrams, you can clearly see the connection and circulation of water and the coolant of the heating system.

Another option could be a boiler of the same type, but without a coil. It will take two containers — large and compact size. Small capacity installed in the middle of a large tank, it will act as a heat exchanger. The coolant will not circulate through the tubes - it passes through the internal compact capacity. The principles of operation and laying of pipes for the circulation of heated water are identical to the first option.

It must be said that the principle of the device of such a device is quite simple, that's why, relying on it, you can invent your own design of an indirect type water heater.

In these boiler options Maybe also the use of electric heating element, which is embedded in capacity from below. Therefore, it is better if the boiler is hung on the wall using brackets. You can also install the case on high legs, which are easy to make from a corner or fittings. The heating element, in fact, is the same boiler, only you need to choose the right power — it will depend on volume boiler. This heating element is available from specialist retailers.

Do-it-yourself assembly and connection instructions

The assembly of the boiler takes place after the preparation of all components.

Holes are drilled in the tank: for the valve for filling with water, for the inlet and outlet of the coolant. If it is decided to install a heating element, then a hole is also made for it from below.

- Next in capacity a coil is installed, and the tubes are led into the holes using special adapters, which are desirable to be welded into the boiler body. Other options are possible, but mainto make sure the holes are sealed.

- Legs are welded to the bottom (if provided).

- A heating element is installed, if it was planned.

- Then the coil is connected to the heating system circuit, according to the diagram.

- Connecting pipe for the supply of cold water and a tap for the selection of heated water. You can immediately do the wiring to the points drawdown — to the kitchen and bathroom.

thermal insulation

In order for water to retain heat for a long time, thermal insulation is produced containers. For her use foil-coated mineral wool or polyurethane foam. The body of the boiler must be completely covered with heat-insulating material. — this will directly depend onPD pribora. To make the insulation look neat, you can place it on top casing from thin sheet metal (for example, galvanized) — get something like this sandwich tube. A visual example is in the first picture of the article.

The principle of operation of the boiler on wood

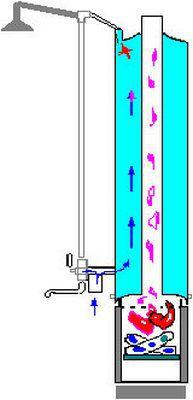

Another type of indirect heating water heater is wood-fired titanium, which will only require the cost of creating a stock. solid fuel. Such a boiler has the design of a samovar and operates autonomously from all sources of energy supply, therefore it is ideal for a device in a private house.

To build such a device with your own hands, you must first arrange a stove, which will heat the water inside the tank. Such a boiler can have a round or square tank, and it can be installed, how on a small stove made of bricks, and on a stove like a potbelly stove, welded from a piece of metal pipe of a sufficiently large diameter.

- The second option is more complicated because have to cut out sections of metal from the pipe for the device in these places of the firebox and blower doors. In addition, by welding inside the pipe, it is necessary to strengthen the brackets for laying the grate. bottom and vepx truby-stove is brewed with solid sheets of metal. There is a round hole at the top him welded in chimney pipe, which will go directly through capacity with water and heat her to the desired temperature.

The tank must also be welded to the furnace lid.

- If it is decided to build the stove out of brick, the boiler tank can be either round or square. The stove is covered from above with a metal panel, in which a chimney pipe is also welded. Further capacity without a bottom (water tank) is hermetically welded to the upper metal plane of the furnace.

Chimney passing through the water capacity, is taken out into the street.

AT tank should be welded two or three nozzles with valves: for water inlet, for outlet to the mixer tap and to the shower.

Water can enter the boiler both from the main line and be filled in manually. In addition, a water storage tank can be installed above the boiler, from which water can also flow into the heating capacity.

If such a water heater is installed in the bathroom, then it will not only provide hot water, but also heat the room.

EveryoneThose who used gas water heaters or flow heaters powered by the mains are familiar with the situation that when the tap opens, you have to wait a while for hot water to go. When installing an indirect heating water heater, this factor is completely eliminated — opening the tap, you can immediately get heated water.

Compared to water heaters running on gas or electricity, this type of boiler will help save on energy costs.

Video: An interesting version of a home-made indirect heating boiler according to the ENKdom project

A ready-made boiler can be purchased at the store and then it remains only to install it in a pre-prepared place. However, its cost is quite high, and if you have the skills to work with the necessary for its manufacture tools, then, having acquired the necessary material, you can do everything with your own hands, while saving a decent amount of money and increasing your self-esteem!))

Hello. Yes, the boiler is easy to make if you have everything you need. But the article missed one important thing - the pressure relief valve and pressure gauge, which are installed on the top cover of the tank, without them the tank can take off. You can also add a tap for a hot water recirculation system - if you need to supply water from the boiler room 10 meters around the house and there is no desire to let a lot of cold water through. To adjust the water temperature, you need a temperature sensor in the tank plus a controller and a three-way valve with an electric drive.

Hello, thanks for the comment. We will draw the attention of a specialist to consider this proposal.