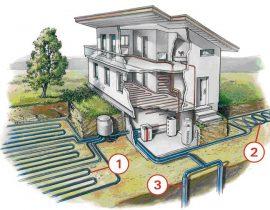

Modern manufacturers produce a wide range of circulation pumps with different technical characteristics, which are used to pressurize autonomous heating systems. This ensures fast and uniform distribution of the heat carrier throughout the system, which increases the efficiency of thermal units and saves heating costs.

Content

- When is it necessary to install a circulation pump in a heating system?

- What gives the installation of circulation pumps in heating systems?

- Types, features

- The best circulation pumps for heating systems

- What to consider when choosing

- Conclusion

- Video advice on how to choose a circulation pump for a heating system

When is it necessary to install a circulation pump in a heating system?

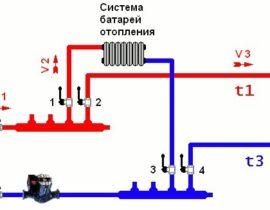

The presence of a circulation pump in the heating system reduces the heating time of the radiators to several minutes. It forcibly accelerates the coolant through the heating system, ensuring uniform circulation of hot liquid. The need for its installation arises in cases where the natural circulation of the coolant cannot cope with heating the house.

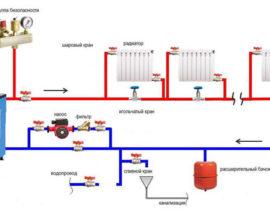

Installation of pumps is carried out immediately when the heating system is installed or during its modernization. Sometimes, errors in the design of heating systems are detected only during operation.

The reason for poor heating of housing construction may be the fouling of the inner walls of the pipes of the system with rust, scale or dirt.

This increases the hydraulic resistance in the heating system and the deterioration of the circulation of the coolant as a whole in it or in individual sections. Installing a pump can help solve the problem of heating a house in such cases without completely replacing the heating system. Trouble-free operation of pumps depends on their correct installation.

What gives the installation of circulation pumps in heating systems?

Modern pumps allow you to adjust the intensity of the coolant supply in the system in automatic mode. Maintaining a constant temperature in it protects the system parts from premature wear, and the uniform movement of the coolant through pipes and radiators increases the service life of the thermal unit and expansion tank.

Among other advantages of installing circulation pumps in the heating system:

- elimination of the possibility of air locks in the system;

- increasing the efficiency of a thermal boiler and reducing fuel consumption for heating a house;

- the possibility of installing heated towel rails and using pipes of small diameter in the device of the heating system.

Types, features

Centrifugal type devices operate on the principle of fluid intake by the impeller and its ejection in a given direction. For suction and discharge, they work with the same efficiency. All circulation pumps used in heating systems are divided into two main groups: with a wet and dry rotor. Each type of device has its own design features.

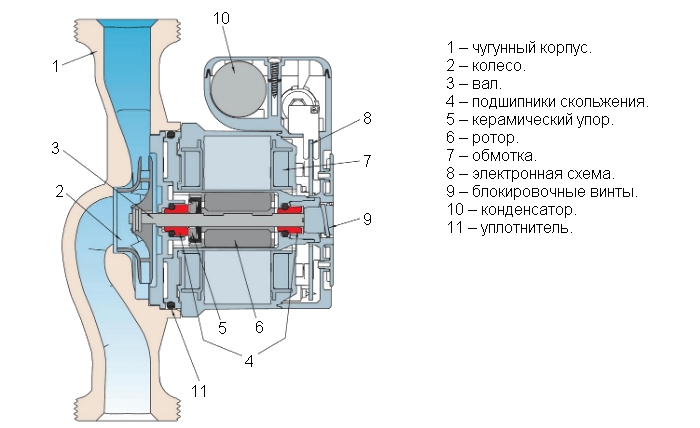

Glandless pumps

Equipment of this type is considered the most suitable for domestic heating systems due to the low noise level they create during operation.In their structure, they are similar to drainage units. Externally, wet rotor pumps can be distinguished from dry designs by the absence of fins on the motor housing and the impeller at its end.

The impeller is mounted directly on the motor shaft. It also has seals on it to prevent leakage. The housing is sealed. For its manufacture use: brass, cast iron, bronze or stainless steel. The pump rotor is most often made of ceramic material. A feature of the design is its direct contact with water.

Centrifugal force is generated inside the pump. The rotating impeller lowers the pressure inside the device housing. This causes fluid to flow. It increases the pressure. The resulting temperature difference creates conditions for pushing the carrier into the system.

Among the advantages of pumps of this type:

- self-removal of air congestion from the system;

- less wear of pump parts;

- self-cooling.

Dry rotor pumps

The device does not have direct contact with liquid. Pumps of this type have the highest efficiency. The structure is cooled by an air system. The main disadvantage of this type of equipment is the increased noise level during operation. Dry rotor circulation pumps are designed to work with large volumes of water. They are preferred when installed in the heating system of industrial facilities.

The best circulation pumps for heating systems

Grundfos UPS 25-40 180

Country of origin - Serbia. The model is one of the most popular and in demand. Installation method - horizontal and vertical. The unit is protected against overheating. It is strictly forbidden to operate the pump for pumping heavily contaminated liquids.The limit of operating temperatures is from 2°С to 110°С. The setting of the unit is mechanical.

Characteristics:

- performance – 2900 l/h;

- power consumption - 45 W;

- pressure - 3.8 m.

Advantages:

- high performance;

- affordable price;

- reliability;

- good pressure.

Flaws:

- more expensive than similar devices of domestic production;

- the model is often faked.

"Whirlwind" TsN-25-4

Country of origin - Russia. The model is designed for pumping hot and cold liquids. Operating temperature range from -10°С to 110°С. The body of the product is made of cast iron. The optimal operating mode of the pump is selected using a special switch.

Characteristics:

- performance – 50 l/min.;

- power consumption - 72 W;

- pressure - 4 m.

Advantages:

- low noise level;

- ease of installation and operation;

- long service life;

- affordable cost;

- profitability;

- compactness.

Main disadvantage

- discrepancy between the characteristics declared by the manufacturer and the actual ones.

Oasis CN 25/4

Country of origin - China. The model with a wet rotor is designed for installation in heating systems designed for space heating up to 100 sq.m. Installation method - horizontal. The body is made of cast iron, the rotor is ceramic. The model can be used for hot water supply and in underfloor heating systems.

Characteristics:

- performance – 170 l/min.;

- power consumption - 245 W;

- pressure - 8 m.

Advantages:

- profitability;

- compactness;

- light weight;

- long service life;

- ease of installation and maintenance.

Flaws:

- not identified.

Grundfos UPS 25-60 180

Country of origin - Denmark. Wet rotor model.It is intended for installation in horizontal and vertical position. There are requirements for the purity of the liquid. Can be used for heating and hot water systems. The product has a bronze body. The pump has 3 operating speeds, with the help of which the pressure in the system is regulated.

Characteristics:

- performance - 4.35 cubic meters / hour;

- power consumption - 60 W;

- pressure - 6 m.

Advantages:

- several speeds of the rotor;

- compactness;

- reliability;

- ease of installation and operation.

Flaws:

- not identified.

Grundfos ALPHA2 25-60 180

Country of origin - Denmark. The low-noise model of the pump differs in high quality of a design. Designed for installation in heating systems low-rise houses. The model has two settings: manual and automatic. The installation method of the device is vertical.

Characteristics:

- performance - 3 cubic meters / hour;

- power consumption - 45 W;

- pressure - 6 m.

Advantages:

- low noise level during operation;

- ease of installation and operation;

- reliability;

- long service life.

Main disadvantage:

- high price.

Valtec VRS 25/4 130

Country of origin - Russia. Wet rotor model with 3-stage speed switch. The body of the product is made of cast iron. Installation method - vertical and horizontal. The maximum operating temperature limit is 110°C. The rotor is cooled by the pumped liquid.

Characteristics:

- performance - 3000 liters / hour;

- power consumption - 72 W;

- pressure - 4.2 m.

Advantages:

- design reliability;

- affordable cost;

- ease of installation and operation.

Main disadvantage:

- short regular power cord.

JEMIX WRF-50/12

Country of origin - Russia. Wet rotor model. The pump has an aluminum single speed motor. The product is intended for installation in heating systems of small cottages. Way of connection with the pipeline - flange. The pump is installed directly into the pipeline.

Characteristics:

- performance – 9600 l/hour;

- power consumption - 550 W;

- pressure - 12 m.

Advantages:

- great pressure;

- reliability;

- high efficiency.

Flaws:

- the need to weld counter flanges to the pipeline;

- high price.

WWQ CN 25/60-180

Country of origin - Russia. Model three-speed with a wet ceramic rotor. The pump is intended for installation in the heating system of low-rise buildings.

Characteristics:

- performance - 58 l./min.;

- power consumption - 90 W;

- pressure - 6 m.

Advantages:

- overheat protection;

- ease of maintenance and operation.

Main disadvantage:

- short network cable.

What to consider when choosing

The determining factor in choosing a circulation pump for a heating system is its performance. To pressurize pipes of large diameter, installation of units with high power is required. When installing pumps in a separate room, the temperature conditions of the equipment must be taken into account.

Among other factors influencing the choice of circulation pumps for heating:

- principle of operation;

- way to connect to the system;

- the number of circuits.

When buying a pump, you should pay attention to the manufacturers' recommendations on space heating standards. These values differ depending on the country in which the unit is installed.

Conclusion

The installation of circulation pumps in heating systems increases the efficiency of the thermal unit. Buildings can be heated in a shorter time. Fuel consumption is reduced.

Video advice on how to choose a circulation pump for a heating system