Due to the high temperature of the coolant, any heating system is under pressure of either liquid or gas, or both of these media simultaneously. Increased pressure can break the weakest parts of the system, cause a flood, and in the worst case, blow up the heating boiler. For safety, it is necessary to install a safety valve that will prevent a sharp increase in pressure in the system.

Content

Safety valve: role in the heating system

The most prone to the formation of steam, and as a result - high pressure, is a solid fuel heating system. In electric and gas boilers, the inertia is much lower, in addition, there is often automation that independently regulates the temperature in the circuit.

When the temperature of the water approaches the point of vaporization, active boiling may begin. Given that the coolant in the system is under pressure, its boiling point will be slightly higher than 1000C, but as soon as someone opens the tap and relieves pressure a little, the steam that appears will begin to burst the pipes and the boiler from the inside. The safety valve will relieve excess pressure, but will not allow water to flow out of the circuit.

Valve device and principle of operation

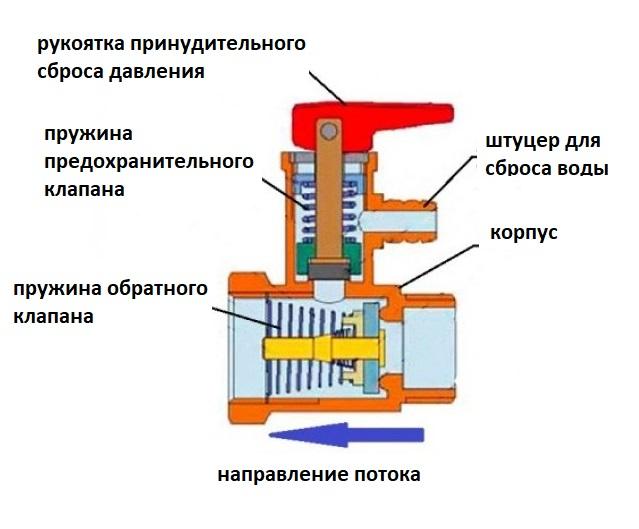

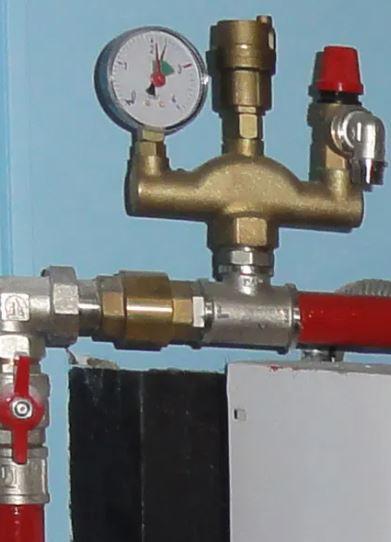

The image shows a combined safety and check valve.

In order, we will deal with the device and the principle of operation of both:

check valve

Used to maintain fluid direction and prevent damage to equipment due to improper operation. Rarely, but there are situations when the water is turned off, someone leaves the tap open - and the air fills the pipes, causing the liquid to flow in the opposite direction.

Many equipment is designed to operate only in single-threaded mode, such conditions of use can damage it. In this situation, the equipment will secure the check valve - a membrane that allows water to pass in only one direction.

It is installed in the direction of fluid flow, due to which its spring (shown in the diagram) is compressed and passes water. If the flow stops and changes its direction, the spring automatically presses again and prevents it from moving back.

Pressure relief valve

It works on a similar principle, but with steam. The spring in each valve is tuned to a certain pressure close to the critical one for the system, at which the steam presses from below on the spring with such force that it is smoothly pressed, relieving excess pressure.

If necessary, the pressure can also be released manually - using the handle on top of the valve.

If necessary, the pressure can also be released manually - using the handle on top of the valve.

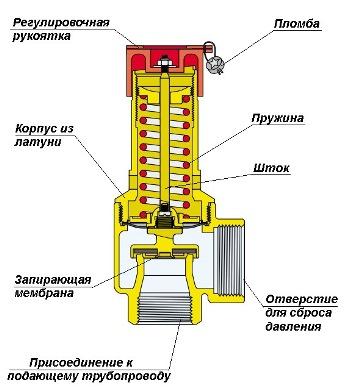

Over time, plaque and scale can accumulate under the valve, due to which the tightness of the sealing ring to the base is violated, and the valve can begin to constantly leak.

In the worst case, constipation may boil to the base - such a valve is no longer able to relieve pressure. Therefore, it is recommended to check all safety devices twice a year.

Valve types

Valves are usually classified according to three criteria, each of which distinguishes two types of devices:

By speed of operation:

- Proportional. They open gradually, allowing steam to exit the circuit smoothly. Does not cause water hammer when closing, so it can be used in both compressible and incompressible media.

- Two-position. When the boundary pressure is reached, it opens abruptly, releasing a large amount of water or gas. Used in both liquid and gas circuits. But it is important to take into account that when closing abruptly, the liquid can cause water hammer, therefore, on-off valves are recommended to be used only with compressible media.

By height of the rise of constipation:

By height of the rise of constipation:

- Partially lifting. They open a short distance, which is why they cannot abruptly release a large amount of gas. Recommended for use in liquid circuits only

- Fully liftable. They open completely, so they can be used in both gas and liquid systems. They allow to release a large volume of medium, significantly reducing the pressure inside the circuit.

According to the device of the mechanism:

- Spring. The spring may lose its tightness over time, it is difficult to regulate the pressure on the locking ring. Can be used on pipes of small diameter in apartments and private houses.

- Lever-cargo. Higher cost, but the pressure can be changed using the weight system. Limited use for wide diameter pipes.

Selection and installation

Of course, when choosing a safety valve, you can rely on the opinion of a consultant, but it is also useful to know the basic principles for choosing it yourself:

- The device must have the necessary marks: if it is a combined check-safety valve, then an arrow indicating the direction of flow, and numbers indicating the maximum allowable pressure, after which the valve is activated. As a rule, it is 6-7 atmospheres.

- Ideally, it is better to purchase a complete security system, which includes not only a valve, but also a pressure gauge and a water discharge valve. The pressure gauge will allow you to adjust to see the pressure force and adjust it in advance without waiting for the valve to operate, and the tap to drain excess water.

- It is advisable to select devices without a manual reset flag switch, as they are easier to accidentally activate. It is better to choose closed with a safety cover.

If the valve does not have a pressure regulator at which it operates, it is necessary to select it much more carefully for your system. As a rule, for a circuit in an ordinary apartment, a valve with a pressure of 3 bar is needed. For stronger and larger circuits, devices with a pressure of 6 bar and above can be used.

Mounting

There are so many rules for installing plumbing and heating equipment that people receive specialized education for this.

However, in the most general terms, the principles for installing a safety valve look like this:

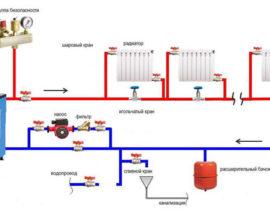

- as a rule, installation is carried out at the point of greatest vaporization - the highest point of the entire system to the stopcock;

- the valve must be installed vertically, with its nose down, so that the escaping steam, firstly, does not burn anyone, and secondly, it can condense inside the tube, which is thus more convenient to lead to the sewer;

- the device becomes on the line with cold water.

The safety valve is screwed on with an adjustable wrench, but without excessive tension to avoid the influence of rotating forces. A thin tube is brought to the spout, which goes into the sewer. The condensed steam will accumulate there.

Do not forget that it is safer to install such an important element in the heating system by a specialist, but it is useful to understand the general principles of installation yourself, so that in the event of a minor breakdown, you can do without calling the wizard. We hope the material was useful to you.

Video review of how the safety valve for heating systems works