A non-return valve is a shut-off device for heating systems that allows you to maintain stable operation of the equipment, preventing the outflow of coolant in the opposite direction. Such units are represented by various types with their own characteristics, advantages and disadvantages.

Content

Principle of operation

types of check valves

The direction of movement of the coolant in the heating system can change under the influence of various factors: uneven cooling of the liquid, violations in the design and installation of the pipeline, breakthroughs. This process can disable both the heating boiler itself and the entire heating system.

For stable fluid movement in only one direction, check valves are used to block the opposite outflow of the coolant. In their design there are locking elements that react to changes in the movement of water in the pipes and automatically block access to it.

A variety of mechanisms are used to block the flow, differing in the principle of operation and characteristics. The device of the units determines the scope of their application.

Valve types

Check valves have the same purpose, but may differ in structure and operation.

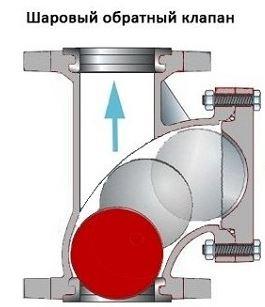

Ball

Ball

The shutter element in such units is a ball made of certain types of metal (steel, aluminum, etc.). The rubber covering of a detail increases its service life.

The coolant flow moving in a certain direction transfers the ball to the upper cavity of the valve.

When changing the course of fluid movement, the element falls to its original position and blocks its path through the pipe.

The advantages of such details:

- possibility of repair - a cover on the upper compartment of the case gives access to the internal mechanism of the device;

- reliability - the device is devoid of moving and friction-forming parts, so that it can work in different positions and be less prone to breakage;

- little hydraulic resistance.

Minuses:

- a significant diameter prevents the use of devices in household systems with a small cross section;

- for horizontal installation, the cover must be located at the top to allow the valve to be raised, vertical installation requires the liquid flow to move upwards;

- low pressure in the system prevents the unit from working properly (a pressure of 25 bar is required to lift the ball).

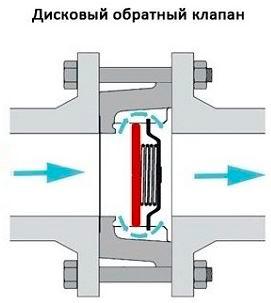

Disk

Disk

Products of this type are equipped with a butterfly valve made of metal or plastic. The size of this element is sufficient to completely block the flow heading in the wrong direction.

A spring made of steel is connected to the disk, which remains compressed during the direct flow of fluid. With a change in the direction of flow, the element straightens and sets in motion a damper that closes the pipe.

A special seal ensures the tight fit of the valve, eliminating leakage.

Such devices are used in home heating systems and have a number of positive qualities:

- do not need periodic maintenance;

- have a low cost;

- have a small weight and compact dimensions, expanding the scope of their application.

The products also have disadvantages:

- impossibility of repair (faulty parts must be replaced);

- high hydraulic resistance;

- deposition of mineral residues leading to failure of the unit;

Petal

Petal

The locking mechanism in structures of this type is a thin steel plate. It is fixed on hinges that set it in motion.

Petal aggregates are of two types:

- single leaf - equipped with a plate rotating around its own axis. The moving coolant lifts the sash, freeing the hole, when the liquid returns, the shutter lowers, blocking the passage. This process occurs with or without the participation of a spring.

- Bivalves - have a pair of plates attached to a rotating axis in the center of the pipe.

Advantages of petal models:

- the ability to work without springs, which allows their installation in gravity pipelines;

- affordable cost.

Flaws:

- increased pressure (especially in double-leaf designs).

lifting

lifting

As part of such devices, there is a spool that freely moves around a vertical axis. Fluid pressure moves the seal off the seat, allowing access to the pipe.

Reducing the pressure or changing its direction returns the spool to its original position, blocking the water.

The advantages of lifting mechanisms:

- low susceptibility to the quality of the passing coolant;

- reliability ensured by the simplicity of the design;

- maintainability - access to components through the top cover.

Minuses:

- Possibility of vertical mounting only.

Features of choice

The main criterion for choosing a check valve is the way it is connected to the piping system. It varies depending on the type and model of the device:

- Coupling products have a threaded assembly that simplifies their connection to the highway. As a rule, this type of fastener is found on disk units that are suitable for installation in independent heating systems of a country house or apartment. Their feature is a small diameter, which usually does not exceed 50.

- Flanged devices contain special holes in their body, with the help of which the mechanism is attached to the pipeline. This type of mounting is stronger than threaded counterparts.

The reliability of the connection allows the use of such products in systems with large pipe diameters. Most often, spherical models are used.

- Wafer units connect two ends of pipes, are light in weight and small in size. This type of installation is typical for petal products.

Some valves require welding for installation. This type is applicable for laying polypropylene pipes.

An equally important characteristic is the material of the unit, it can be of several types:

An equally important characteristic is the material of the unit, it can be of several types:

- Stainless steel - the best choice for systems with a diameter of up to 0.04 m. Such structures are resistant to corrosion processes, endure loads up to 10 atm. Steel valves are quite expensive, but they can last a long time without breakdowns.

- Brass - a more affordable material, but susceptible to corrosion, although it appears rather slowly.Such devices are also inferior to steel models in terms of strength, but they tolerate high loads quite well.

- Cast iron - the most reliable option for working with maximum coolant pressure. Products of this type are quite bulky and heavy. The specifics of manufacturing allows the production of cast iron only elements over 40 mm in diameter. This factor limits the use of such devices in autonomous highways.

Popular ball models

A number of devices that use a metal ball to seal the liquid and are of low cost.

Tim JH-1014

- body and locking structure material – brass;

- limit temperature - 130 ° C;

- connection type - coupling (BP / BP);

- price - 660 rubles.

Valve for use in the installation of hot and cold water supply, heating, transmission of compressed air, gases and liquids that do not interact with the material of the product. The model has no rubbing surfaces, it can be mounted in any position without changing the characteristics.

The spherical chamber contributes to an increase in throughput compared to cylindrical counterparts. The working pressure of the valve is from 0.05 bar.

1″ ALTSTREAM

- thread type - 1 ″;

- temperature range - from -20 ° C to 150 ° C;

- tightness of the locking element - class A;

- material - brass;

- type of flow - full bore;

- price - 400 r.

The spherical design is used for locking pipeline systems for domestic and drinking purposes, heating, hot water supply, compressed air. The service life of the product is 30 years, there is a possibility of repair. The minimum resource of development is 25 thousand cycles.

The best petal varieties

Unit models with one or two blocking plates.

TIM 1 Vn, JH-1012C

- product type - straight;

- threaded diameter - 1 inch;

- case material – brass;

- limit temperature - 120 ° C;

- working pressure - 40 bar;

- type of thread - internal;

- price - 303 rubles.

The flap valve is equipped with a horizontal damper. Mounted in heating systems, without pump circulation. The device operates at low pressure, does not create strong resistance to the flow of water, unlike spring units. The shutter has a rubber seal.

TIM 1 1/4 Female, JH-1013C

- threaded diameter, inch - 1 1/4;

- working pressure - 25 bar;

- material - brass;

- coverage - no

- limit temperature - 120 ° C;

- price - 399 rubles.

Petal model for non-volatile and pumpless heating systems, made of reinforced brass for sanitary purposes. It can operate at minimum pressure, is equipped with a threaded connection, has a guarantee of 1 year.

lifting product rating

More expensive products with a coolant blocker in the form of a spool.

Zetkama V277 Du-15

- conditional diameter - 15 mm;

- connection - threaded (P/P);

- material - cast iron;

- limit temperature - 200 ° C;

- working pressure - 16 bar;

- price - 2798 p.

The device is placed on pipelines intended for the transportation of cold and hot water for technical purposes, neutral media, and steam. Installation is made horizontally or vertically.

Armafit 16kch9p - DN32 Ru25

- working pressure - 1.6 MPa;

- limit temperature - 225 ° C;

- accession - flange;

- working media - steam, water;

- temperature conditions of use - from -30 to 50 ° C;

- price - 3650 r.

Flanged unit for blocking steam and water flows.The version with rubber spool seal can operate at temperatures up to 50 °C, and with paronite or bronze - up to 225 °C. The cover and main structure are made of cast iron, the spool is made of steel.

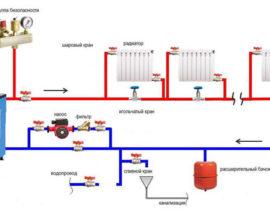

Installation rules

When installing a check valve, there are several important points to consider:

- The product is placed only in the direction of the liquid flow. To facilitate selection of the correct side, the valve body has a special marking in the shape of an arrow.

- For better fixation of devices, it is permissible to use paronite seals, but only if they do not narrow the bore diameter of the pipe, otherwise the pressure on the system will be excessively increased.

- The part is placed in such a way that other parts of the pipeline structure do not create additional load on its body.

- Before the locking device, it is desirable to install a special mesh for primary cleaning of the coolant. It will trap large particles that can weaken the tightness of the unit when it enters the mechanism.

For lines with forced circulation, any type of check valves can be used, and for gravity circuits, only rotary-type petal models that do not have a spring are applicable.

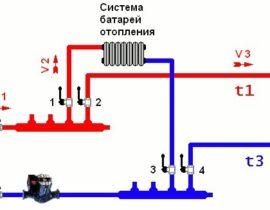

The locking mechanism must be installed on multi-circuit systems equipped with a circulation pump.

It is also necessary to install the valve on heating circuits with bypass. As a rule, they are created for the transition from gravity to artificial circulation. The valve is fixed on the bypass in a position parallel to the circulation pump.

Shut-off valves are also recommended to be installed on the make-up system.This will prevent the pipeline from emptying in various situations. For example, opening a tap on the make-up pipe to increase pressure, if the water supply is blocked at that time, can lead to complete drainage of the system and shutdown of the boiler.

Choosing the right valve is also important. To block unwanted flows between adjacent circuits, petal or disk units should be installed. The first option will create less resistance, which is also important to consider during installation.

A non-return valve is not required for all types of heating equipment. But it is necessary for the formation of bypass circuits, multi-loop systems. When choosing, you should take into account the characteristics and features of individual models, as well as options for their connection.

Video review of why you need a check valve in the heating system