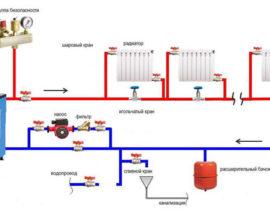

The problem of maintaining a comfortable temperature, solved in most apartment buildings by connecting to centralized heating, in a private house sometimes requires the use of complex and expensive technical devices.

The main task in this case is to find the optimal balance between the cost of heating equipment and pipelines, their efficiency, estimated resource and operating costs. Three-way valves are designed to simplify temperature control, as well as create a comfortable microclimate in individual rooms with minimal losses.

Content

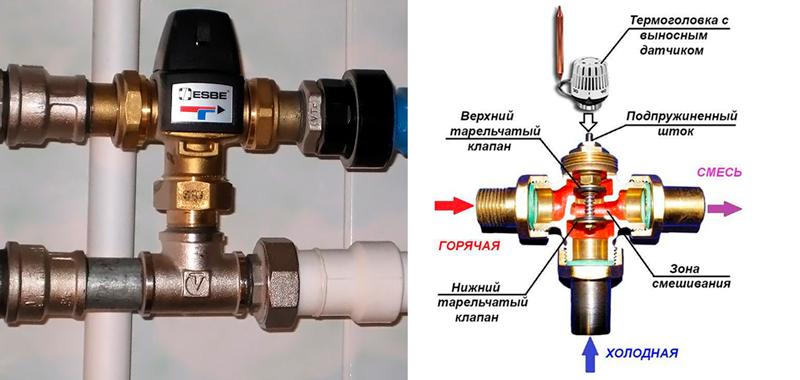

The device and principle of operation of the three-way valve

A three-way valve is a specific type of shut-off and control valve capable of controlling the ratio of cold and hot flows in two closed circuits. Simply put, it adds another one to the main heating circuit, in which you can maintain the same temperature, or change it by adjusting the valve as you wish.

A distinction should be made between a three-way valve and a three-way valve.The work of the first is accurate and partly automated, which not only affects the overall reliability and efficiency of the heating system, but also simplifies the creation of complex multi-loop circuits.

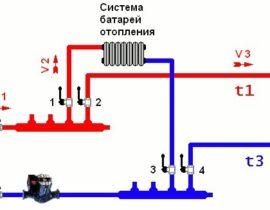

Conventionally, a three-way valve can be represented as a pair of two-way valves, the operation of which is inversely proportional: opening one leads to covering the other by an equal amount. It is important to understand that in this case the overall flow rate remains unchanged.

Depending on the principle of operation, there are three main groups of three-way valves:

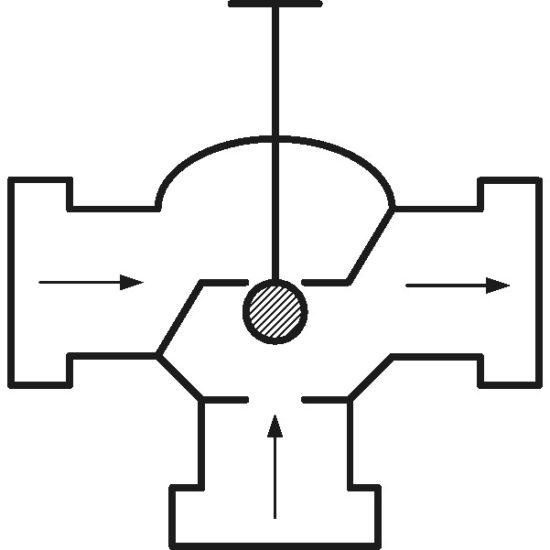

Mixing three-way valve

It has two inlets and one outlet. It is used to control the temperature of the slave circuit by mixing two separate streams with different temperatures in a user-defined proportion.

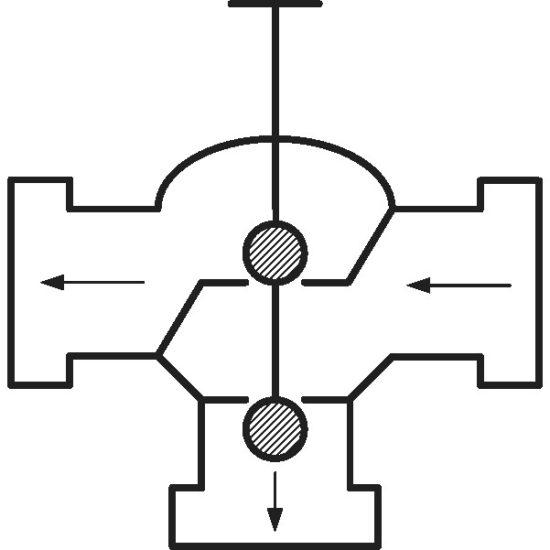

Dividing three-way valve

It has one inlet and two outlet pipes. It is used to control the temperature by changing the amount of coolant circulating in the slave circuit, as well as in front of additional heating / cooling systems - they are supplied with the part of the flow selected by the valve.

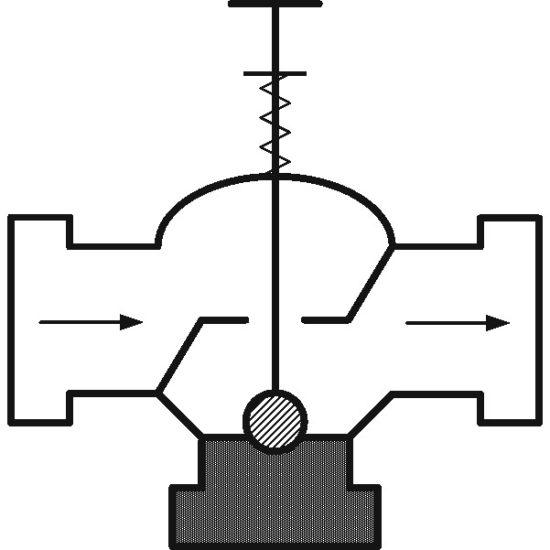

Change-over three-way valve

Able to switch the flow between circuits without affecting its temperature and intensity. Switching can be carried out according to the “input-input-output” or “input-output-output” scheme.

The figures above show diagrams of 3-way seat type valves. There are also swivel-type designs, but they are less durable and can only be installed in circuits with low internal pressure. In most cases, purchasing a seat valve is preferable.

Externally, the three-way valve is a T-shaped cylindrical fork, the ends of which are equipped with a unified thread.In models designed for high flow rates, the end flange can play the role of a connecting element.

Valve bodies are made of materials common in heating systems: cast iron, stainless steel, brass, bronze. The element of a three-way valve that regulates the outgoing flow or flows is called a shutter.

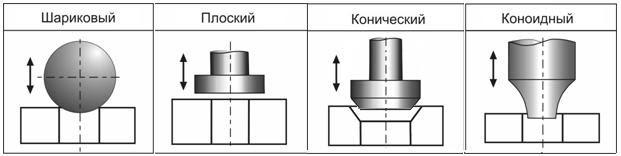

Structurally, it can be:

- ball - characterized by smooth operation, but can wear out faster than analogues of other forms;

- cylindrical or flat – has an increased resource due to a larger area of contact with the socket;

- conical – allows to reduce the dimensions of the valve.

The valve seats are usually equipped with a seal made of an elastic material, which increases tightness and reduces wear on the interacting parts. However, a single valve is not enough to switch or regulate fluid flows.

The valve must be equipped with a reliable drive system, which can be:

Mechanical - regulation of the operating mode is carried out by turning the head to the required angle.

Mechanical - regulation of the operating mode is carried out by turning the head to the required angle.- Electronic – the angle of rotation of the shutter is set by an electric servomotor, the signal to which is transmitted by a sensor or climate control system.

- thermostatic - the design of the valve is supplemented with a thermal element, which, when the temperature of the coolant rises by a certain value, expands, turning the shutter.

Manually operated three-way valves are the most reliable, although they do not provide the same flexibility and speed of adjustment as their automated counterparts.In addition, the life of a valve of any type is greatly affected by the presence of abrasive particles in the coolant, so it is recommended that circuits operating with such high-precision fittings be equipped with trapping filters.

Choosing a three-way valve for the home

Before heading to the store or to popular web sites for three-way valves, it is important to understand what properties they should have. First of all, the total number of circuits in the future heating system is determined, because each circuit will require the installation of a separate valve, which, by the way, can differ significantly from each other in their design and properties.

For each of them, you will need to define:

- type of work: separation, switching or mixing;

- material for the manufacture of the body and internal parts;

- actual and required temperatures in the circuit;

- calculated coolant pressure in the system;

- required throughput;

- valve control features;

- standard for connecting to pipelines (in some cases, adapters can be used).

More specific data may be required, for example, information about the oxidizing properties of the coolant, the compatibility of electronically controlled valve blocks with a specific climate control system, etc.

There are many three-way valves on the modern market for every taste and budget. In the most budgetary niche, the Chinese brands TIM and ViEiR are leading, whose products have surprisingly good assembly.

A class above is the domestic Valtec, created in collaboration with Italian engineers, and imported Esbe, Honeywell and Danfoss play in the top league. Below is a brief overview of the most popular three-way valve models for domestic use.

Tim BL7661X04

Characteristics:

- Type: mixing

- Control: thermostatic

- Material: cast iron/brass

- Connection: 25mm thread

Advantages:

- Cheap, easy to install and set up

Flaws:

- Shock sensitive housing, poor thermostat accuracy

Tim BL3804

Characteristics:

- Type: mixing

- Management: mechanical

- Material: brass

- Connection: 25mm thread

Advantages:

- Good balance of price and workmanship, ease of installation

Flaws:

- Unstable operation in loaded circuits, rapid wear of the internal mechanism

ViEiR VR291

Characteristics:

- Type: mixing

- Management: electronic

- Material: brass

- Connection: 25mm thread

Advantages:

- Ability to work with an electronic drive, low cost

Flaws:

- Unstable operation in loaded circuits, rapid wear of the internal mechanism

Tim BL8804

Characteristics:

- Type: mixing

- Control: thermostatic

- Material: chrome plated brass

- Connection: 25mm thread

Advantages:

- High-quality thermostat, fast and smooth flow control, high quality workmanship

Flaws:

- Durable chrome finish

Uni-Fitt H.R. one

Characteristics:

- Type: spacer

- Control: mechanical or thermostatic

- Material: brass

- Connection: 25mm thread

Advantages:

- Ability to work with different types of drive, high quality, reliability and durability

Flaws:

- Difficulties in using for mixing flows, in fact, the valve can only be used uninterruptedly in dividing mode

Esbe VRG131

Characteristics:

- Type: mixing

- Control: mechanical Material: brass alloy

- Connection: 25mm thread

Advantages:

- Very high quality materials and workmanship, trouble-free operation in all conditions

Flaws:

- Difficulties in using external drives

Valtec Thermomix MT10RU

Characteristics:

- Type: mixing

- Control: thermostatic

- Material: nickel plated brass

- Connection: thread 12mm

Advantages:

- High quality workmanship, reliable and aesthetic coating that prevents oxidation of the case, stable operation

Flaws:

- Thermostat aging tendency, not the most common thread standard

Stout SVM-0070-300025

Characteristics:

- Type: switching

- Control: electronic or thermostatic

- Material: brass

- Connection: 25mm thread

Advantages:

- Resistant to significant loads and high temperatures, prompt switching of flows

Flaws:

- Unsuitable for smooth control

Stout SVM-0003-015001

Characteristics:

- Type: mixing

- Management: mechanical

- Material: brass

- Connection: thread 50mm

Advantages:

- Resistant to significant loads and high temperatures, high quality workmanship

Flaws:

- Mounting standard rarely found in domestic conditions

ESBE 3F 50

Characteristics:

- Type: combined

- Management: electronic

- Material: cast iron

- Connection: flange

Advantages:

- Ability to work in the most difficult operating conditions, very high quality workmanship and assembly, the presence of a high-power electronic drive

Flaws:

- Mounting standard rarely found in domestic conditions

Danfoss VRB3

Characteristics:

- Type: combined

- Management: electronic

- Material: bronze

- Connection: 25mm thread

Advantages:

- Uncompromising workmanship and assembly, durable materials, versatility, the ability to connect any drive

Flaws:

- High price

We hope this review was useful and helped you to choose a three-way valve that fully matches the features of your heating system. We wish you warmth in your home!

Video advice on how to properly install a three-way valve