A single-pipe heating system is most often used for heating low-rise buildings. It has a simple, budget and reliable design. Systems of this type can be non-volatile or have modern equipment and differ in automatic operation.

Content

Principle of operation

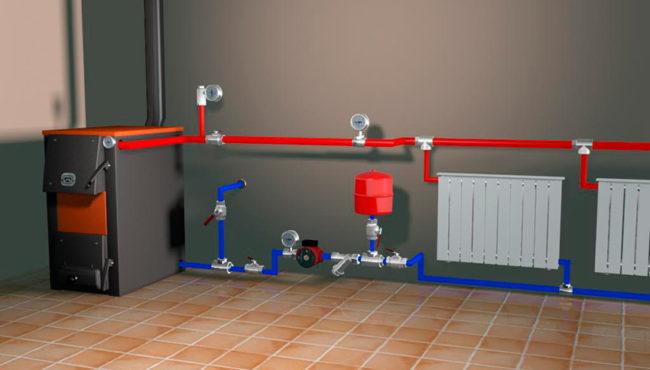

The functioning of a single-pipe line is carried out by constant circulation of the coolant through the branches of the system. As it moves from the boiler to the radiators, it gives off heat and heats the room, and then returns to the original reservoir to repeat the cycle.

Steam, antifreeze, air or water can act as a heat carrier. The last option is the most common.

The principle of operation of a classical heating system consists of several stages:

- The boiler heats the liquid, from which it expands and forms pressure in the pipes.

- The density of the coolant decreases, and it loses weight.

- Cold and heavier water pushes the heated liquid up. To ensure this process, the nozzles coming from the boiler are always installed in an upward direction.

- Under the influence of the resulting pressure, gravity and convection, the liquid enters the batteries, heats them up.

- Cooling down, the coolant returns to the heating source, repeating the process.

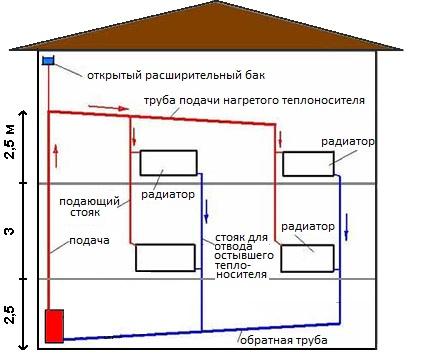

In gravity heating systems, a certain angle of inclination of the branches running horizontally (per 1 linear meter - 2-3 mm) is required to ensure stable flow.

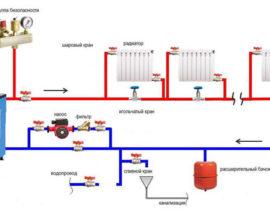

Heating water increases its volume, from which a hydraulic pressure is created in the system. But even a small increase in pressure above normal due to the lack of fluid compression can cause pipeline failure. To compensate for the pressure in such schemes, a special expansion tank is mounted.

Application

It is advisable to place single-pipe heating structures in buildings with a height of 1-2 floors and an area of up to 150 square meters. m.

This approach will preserve the aesthetic appearance of the room, thanks to a smaller number of pipes, as well as save on the purchase of necessary materials and components.

This approach will preserve the aesthetic appearance of the room, thanks to a smaller number of pipes, as well as save on the purchase of necessary materials and components.

For rooms with a small area, standard gravity-flow systems show greater efficiency. This option provides for direct connection of the batteries to the main pipeline.

Placing 2-3 radiators does not require the installation of a large number of locking elements. It is easier to drain the fluid from the system itself, if necessary.

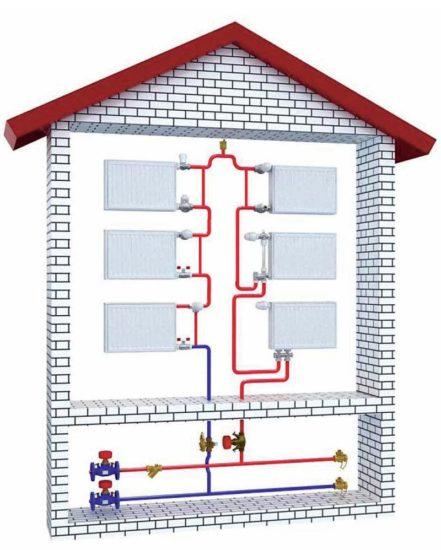

Heating schemes in large-sized buildings they have a complex structure with various branches and components. Here, the best solution would be to install a pipeline with forced movement of the coolant, a diagonal tie-in of batteries and regulators in the form of bypasses.

Types of structures

Heating systems can have natural or forced (artificial) circulation of the coolant

The first option is the classic type of line formation with an expansion tank, which is mounted under the ceiling and receives heated water from a boiler or stove. The liquid moves by gravity through the tubes to the batteries.This method is reliable and easy to arrange, optimally performs its tasks in rooms with a small area.

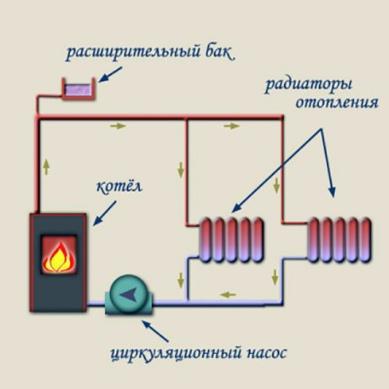

Modern appliances are almost universally equipped with built-in pumping systems for circulation. They allow you to organize more complex and large-scale heating mains for large areas.

For solid fuel boilers pump connected separately. This is due to the strong heating of the equipment during fuel combustion.

Heating circuits can also be closed and open:

- Old heating options often had an open type of design.. With heating, the level of liquid in the tank increased and decreased as it cooled. A special branch pipe served to release steam and excessive pressure to the street or into the sewer to prevent overheating of the line.

- Modern closed-type devices for this purpose are equipped with an expansion tank that compensates for pressure growth.. For solid fuel units, a larger tank, as well as a valve for removing steam and automatic water make-up.

Pros and cons of the system

Among the main advantages of single-pipe heating, the following can be distinguished:

- Convenient and simpler masking of pipes in walls and niches.

- Quick installation.

- Optimal for organizing heating on several floors. In this case, only one line will need to be drawn through the floors.

- Closed systems are easily adjusted using a radiator valve.

- Laying a single pipeline is cheaper than installing double systems.

Such systems also have some disadvantages:

- Cooling of the coolant during the transition to remote batteries.The cross section of the pipeline and the number of sections are limited in terms of extension. For optimal system performance, the circuit may contain 4-5 batteries.

- For a good coolant current, it is necessary to mount full-bore elements on the branches. An increase in the resistance of the reinforcement pushes the fluid in a straight line, reducing its flow.

- Hydraulic instability, manifested in the impact of the state of one radiator on others in the branch. For example, blocking the valve on the first unit will cause the temperature in subsequent battery packs to rise, which will start to overheat the room.

- Higher costs than mounting a shoulder system consisting of a pair of pipes.

- The difficulty of calculations and balancing. The size of the heat-releasing surface and the power of the devices should be determined extremely accurately.

- Large tube sizes.

Wiring diagrams

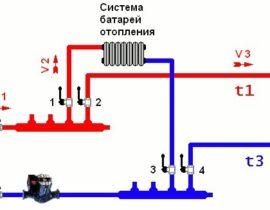

The option of connecting batteries to the main affects the degree of their heat transfer.

There are three types of radiator connections:

- Lateral - provides uniform heating of all radiator compartments. The inlet and outlet tubes are connected on the same side of the instrument. Maximum heat transfer is achieved when the flow is organized from top to bottom.

- Diagonal - the most efficient design option, which achieves the best heating of the battery surface, minimizes heat loss. The supply pipe is connected to a branch pipe in the upper part of the radiator, and the part of the pipeline responsible for the outlet is connected to a similar lower element in the opposite part of the device.

- lower - a less efficient type of connection, but often used (for example, to place a pipeline under the floor). The inlet and outlet are placed on the lower radiator pipes from opposite sides.

Multi-section heating systems are installed only with a diagonal connection option.

Single-pipe systems have proven themselves well in arranging heating for houses with a small number of floors and an average floor area. They are quite compact and easy to install, easily hidden under the floor or in wall niches without disturbing the appearance of the interior.

Video review of errors during the installation of a single-pipe heating system