Wood is a rather complex material in terms of its chemical composition.

Why are we interested in chemistry? Why, combustion (including burning wood in a stove) is a chemical reaction of wood materials with oxygen from the surrounding air. The calorific value of firewood depends on the chemical composition of a particular type of wood.

The main binding chemical materials in wood are lignin and cellulose. They form cells - a kind of container, inside which there is moisture and air. The wood also contains resin, proteins, tannins and other chemical ingredients.

Content

What determines the calorific value of firewood?

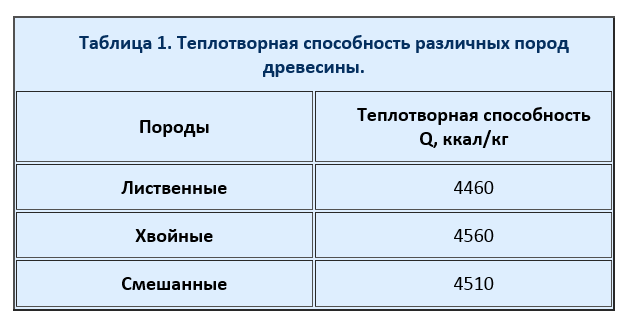

The chemical composition of the vast majority of wood species is almost the same. Small fluctuations in chemical composition various breeds and determine differences in the calorific value of different types of wood. Calorific value is measured in kilocalories - that is, the amount of heat obtained by burning one kilogram of a tree of a particular species is calculated. There are no fundamental differences between the calorific values of different types of wood.And for domestic purposes, it is enough to know the average values.

Differences between rocks in calorific value appear to be minimal. It is worth noting that, based on the table, it may seem that it is more profitable to buy firewood harvested from coniferous wood, because their calorific value is greater. However, on the market, firewood is supplied by volume, not by mass, so there will simply be more of it in one cubic meter of firewood harvested from hardwood.

Harmful impurities in wood

During the chemical combustion reaction, the wood does not burn completely. After combustion, ash remains - that is, the unburned part of the wood, and during the combustion process, moisture evaporates from the wood.

Ash has less effect on the quality of combustion and the calorific value of firewood. Its amount in any wood is the same and is about 1 percent.

But the moisture in the wood can cause a lot of problems when burning them. So, immediately after felling, wood can contain up to 50 percent moisture. Accordingly, during the combustion of such firewood, the lion's share of the energy released with the flame can be spent simply on the evaporation of the wood moisture itself, without doing any useful work.

The moisture present in wood dramatically reduces the calorific value of any firewood. Burning firewood not only does not fulfill its function, but also becomes unable to maintain the necessary combustion temperature. At the same time, the organic matter in the firewood does not burn out completely; when such firewood burns, a suspended amount of smoke is released, which pollutes both the chimney and the furnace space.

What is the moisture content of wood, what does it affect?

The physical quantity that describes the relative amount of water contained in wood is called moisture content. The moisture content of the wood is measured as a percentage.

When measuring, two types of humidity can be taken into account:

- Absolute moisture content is the amount of moisture that is contained in the wood at the current moment in relation to a completely dried tree. Such measurements are usually carried out for construction purposes.

- Relative humidity is the amount of moisture that wood currently contains relative to its own weight. Such calculations are made for wood used as fuel.

So, if it is written that wood has a relative humidity of 60%, then its absolute humidity will be expressed as 150%.

To calculate the calorific value of firewood at a known moisture content, you can use the following formula:

Analyzing this formula, it can be established that firewood harvested from coniferous wood with a relative humidity index of 12 percent will release 3940 kilocalories when burning 1 kilogram, and firewood harvested from hardwood with comparable humidity will already release 3852 kilocalories.

To understand what a relative humidity of 12 percent is, let's explain that such humidity is acquired by firewood, which is dried for a long time on the street.

Density of wood and its effect on calorific value

In addition to moisture content, another factor affects the calorific value of firewood, namely density. This is a common physical quantity showing how much weight of a substance falls on a standard volume (usually one cubic meter).

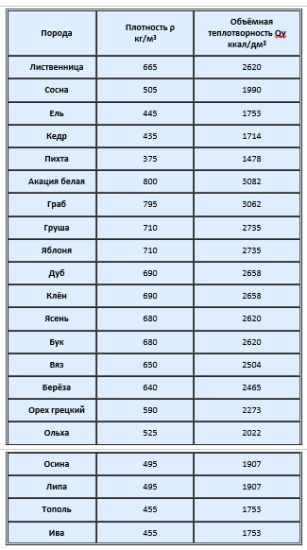

To estimate the calorific value, you need to use a slightly different characteristic, namely the specific calorific value, which is a value derived from density and calorific value.

Experimentally, information was obtained on the specific calorific value of certain types of wood. Information is given for the same moisture content of 12 percent. Based on the results of the experiment, the following table:

Using the data from this table, you can easily compare the calorific value of different types of wood.

What firewood can be used in Russia

Traditionally, the most favorite type of firewood for burning in brick kilns in Russia is birch. Although, in fact, birch is a weed, the seeds of which easily cling to any soil, it is extremely widely used in everyday life. An unpretentious and fast-growing tree has faithfully served our ancestors for many centuries.

Birch firewood has a relatively good calorific value and burns quite slowly, evenly, without overheating the stove. In addition, even the soot obtained by burning birch firewood is used - it includes tar, which is used both for domestic and medicinal purposes.

In addition to birch, aspen, poplar and linden wood is used as firewood from hardwoods. Their quality compared to birch, of course, is not very good, but in the absence of others, it is quite possible to use such firewood. In addition, linden firewood emits a special aroma when burned, which is considered beneficial.

Aspen firewood gives a high flame. They can be used at the final stage of the firebox to burn off the soot formed by burning other firewood.

Alder also burns quite evenly, and after combustion it leaves a small amount of ash and soot. But again, in terms of the sum of all the quality, alder firewood cannot compete with birch firewood. But on the other hand - when used not in a bath, but for cooking - alder firewood is very good. Their even burning helps to cook food efficiently, especially pastries.

Firewood harvested from fruit trees is quite rare. Such firewood, and especially maple, burns very quickly and the flame reaches a very high temperature during combustion, which can adversely affect the condition of the stove. In addition, you just need to heat air and water in the bath, and not melt the metal in it. When using such firewood, it must be mixed with firewood with a low calorific value.

Softwood firewood is rarely used. Firstly, such wood is very often used for construction purposes, and secondly, the presence of a large amount of resin in coniferous trees pollutes furnaces and chimneys. It makes sense to heat the stove with coniferous wood only after a long drying time.

How to prepare firewood

Firewood harvesting usually begins in late autumn or early winter, before permanent snow cover is established. Felled trunks are left on the plots for primary drying. After some time, usually in winter or early spring, firewood is taken out of the forest. This is due to the fact that during this period no agricultural work is carried out and the frozen ground allows you to load more weight on the vehicle.

But this is the traditional order. Now, due to the high level of development of technology, firewood can be harvested all year round.Entrepreneurial people can bring you already sawn and chopped firewood any day for a reasonable fee.

How to saw and chop wood

Saw the brought log into pieces that fit the size of your firebox. After the resulting decks are split into logs. Decks with a cross section of more than 200 centimeters are pricked with a cleaver, the rest with an ordinary ax.

The decks are pricked into logs so that the cross section of the resulting log is about 80 sq.cm. Such firewood will burn for quite a long time in a sauna stove and give off more heat. Smaller logs are used for kindling.

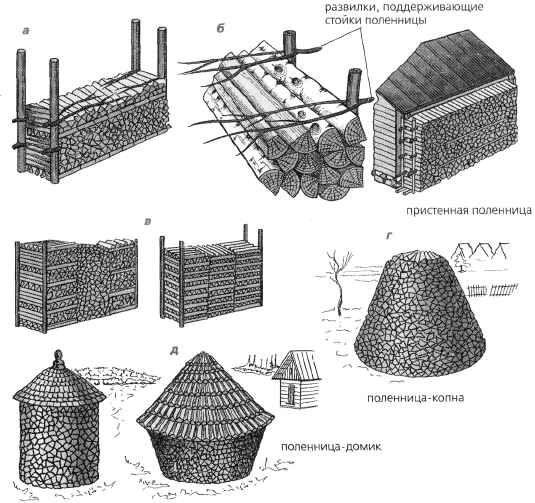

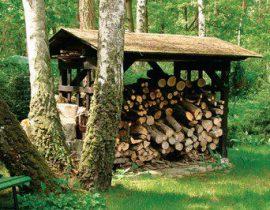

Chopped logs are stacked in a woodpile. It is intended not only for the accumulation of fuel, but also for drying firewood. A good woodpile will be located in an open space, blown by the wind, but under a canopy that protects the firewood from precipitation.

The bottom row of woodpile logs is laid on logs - long poles that prevent firewood from contacting wet soil.

Drying firewood to an acceptable moisture content takes about a year. In addition, wood in logs dries much faster than in logs. Chopped firewood reaches an acceptable moisture content already in three months of summer. When dried for a year, firewood in a woodpile will receive a moisture content of 15 percent, which is ideal for combustion.

Calorific value of firewood: video