It seems that it is very easy to kindle the stove, just throw in firewood, some coal, splash lighter fluid and a flaming match. But by no means should this be done.

coal for the furnace

The stove should be treated with care, observing all fire regulations and carefully monitoring the condition of the stove structure itself.

Coal is used in order to ensure uniform long-term heating of the furnace and the room as a whole. In addition, it is much more profitable to heat the stove with them than with firewood alone.

Content

Types of coal

The origin of coal is vegetable. This rock mainly consists of carbon and non-combustible impurities that form ash during combustion. In coals mined in different areas, the amount of impurities is not the same. Sulfur contained in the rock, when burned, forms oxides, which in the atmosphere turn into sulfuric acid. Especially a lot of sulfur is found in lingit. Coal is divided into several types, depending on its characteristics.

Age criteria:

- lingit (used in power plants because of its friability and crumbling properties, the youngest type of coal);

- brown coal;

- coal;

- anthracite (has the most ancient origin).

Humidity (W) and content of volatile impurities (VH):

- lingit

- brown coal: B = 30 to 40%, LP > 50%;

- hard coal: B = 12 to 16%, LP = 40%;

- anthracite: B = LP = 5-7%.

Specific heat of combustion:

- brown coal - 3-5 thousand kcal / kg;

- coal - 5-5.5 thousand kcal / kg;

- anthracite - 7.4-9 thousand kcal / kg.

Which stoves are designed for kindling coal

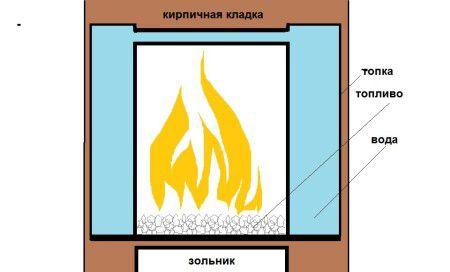

The combustion temperature of coal is higher than the combustion temperature of logs. Therefore, special design furnaces are heated with coal. Theoretically, ordinary brick ovens can also be fired with coal, but the furnace must have thickened walls, and the grate should be located two rows lower. In addition, the design must have a separate exhaust system designed for coal, not connected to other systems.

Sometimes in furnaces, inside the firebox, two boilers with water are installed, which serve to heat the room and protect the brickwork from overheating. In such structures, it is necessary to ensure that there is always water in the pipes.

The ash pan and the grate must necessarily match each other in size so that there is no heat loss. To enhance the draft, special nozzles are used on the stove.

The sauna stove can also be fired with coal if its wall thickness exceeds 35 mm, otherwise it may collapse from exposure to high temperatures!

Causes of smoke

- Formation of a blockage in the flue riser or furnace channels.

- Cracks in the oven lining. Due to their appearance, thrust and flue gas temperatures decrease.

- Destruction of the inner masonry of the furnace.

- Strong cooling of the chimney and the entire structure of the furnace.

- The stove can smoke if, in parallel with another stove, it is connected to the same chimney without a special divider (smoke damper).

Preparing the stove for kindling

Before lighting the oven, check its serviceability and prepare for kindling. This is especially true in country cottages, where the stove is used infrequently, upon the arrival of the owners.

- Visually inspect the oven for cracks in the masonry. If they are present in the room, smoke, carbon monoxide can enter, moreover, when heated, the crack can increase and damage the masonry even more. If cracks are found, they are sealed with a mixture of clay and sand.

- We check the presence of whitewash on the pipe (in the attic and roof).

- It is undesirable to place combustible, especially flammable, objects closer than half a meter from the hot walls of the furnace. Also, do not stack dry firewood close to the stove.

- It is recommended to clean the pipe 2-3 times a month (with constant use).

- Before kindling, clean the oven. We fill the slag and ash with water and remove it with a poker, removing it to a specially designated place. The outer walls of the oven are cleaned of dust with a dry cloth. If this is not done, the dust will cause an unpleasant odor.

- Pieces of bitumen, household and construction waste, plastic, etc. must not be used for kindling.

- Do not open both the blower and the oven door at the same time.

- In order not to overheat the stove, it is heated several times a day, the duration should not exceed two hours.

- Coal for kindling is chosen dry, of medium size. Before loading into the oven, it is cleaned of dust. If the fuel is wet, then when heated, the moisture becomes steam, which turns into condensate, which settles on the pipe walls, mixes with soot and cools the structure.

- Flammable liquids (kerosene, gasoline, etc.) must not be used for ignition.

- It is impossible to leave the stove unattended during kindling, especially if there are children and animals in the house.

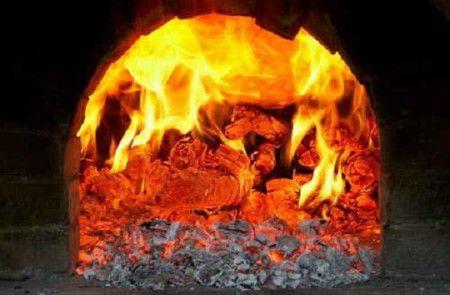

How to heat a stove with charcoal

- We clean the stove from ash and soot, prepare coal.

- At the bottom of the firebox we lay a layer of crumpled newspapers or paper, on top - a layer of medium-sized wood chips.

- On top of the chips we lay dry firewood of a small size, such as birch. To make the burning of firewood more efficient, they are laid in a “well” or “hut” (with a sufficiently large volume of the chamber in which the fuel is burned), leaving space between the firewood for free air circulation.

- You can kindle newspapers with ordinary matches, or with a special spray can.

- Close the oven door. And we open the blower. With its help, we regulate the intensity of combustion - the greater the air flow, the stronger the flame in the furnace.

- When the firewood burns out, and a layer of hot coals forms, we pour a layer of fine coal (about fifteen centimeters) into the oven.

- When opening the firebox door, the blower should be closed.

- After the sprinkled layer of coal flares up, it is increased to sixty centimeters (larger fraction).

Important! During the burning of coals, they should be stirred up a little for better air circulation and to prevent sintering of the mass.

Coal is laid through the firebox door or through the shifted burners of a metal plate. The second option is more convenient and safer.

If, after using coal, coal dust remains in the place of its storage, then you should not throw it away, it is more economical to use it for heating.

For ignition, a piece of steel pipe is used. Small firewood and a layer of coal of a large fraction are loaded into it. Outside, the pipe is covered with wet fine coal. After that, the pipe is pulled out through the holes in the stove and firewood is kindled. Fuel is added after the previous layer has burned through.