A private bath is always a health benefit and relaxation and pleasure from visiting it. Usually baths are built from wooden beams, and stoves and boilers with water are installed inside the steam room. The temperature regime in the bath, air humidity and steam intensity depend on the type of furnace. The choice of the type of bath (Russian, Finnish sauna or Turkish bath) depends on the health and desire of the owners.

Video: how to make a potbelly stove with your own hands

The stove in the bath should have an aesthetic appearance, keep warm for a long time, be safe and easy to use, and not have components in the masonry that emit toxic substances into the atmosphere when heated. Under no circumstances should smoke from a wood-burning stove enter the steam room. It is worth considering the possibility of dismantling the stove for its maintenance (for example, to replace failed elements) and the compactness of the stove, especially in small baths.

There are several rules for metal stoves that I install in baths:

- wood stoves (potbelly stove) are installed on a concrete foundation or on a sheet of metal as fire safety;

- for the same purpose, they maintain a distance of about half a meter from all metal surfaces of the furnace to the wooden lining (or use heat-insulating materials in combination with steel sheets).

Important! For long and safe operation of the furnace, the structure is assembled from alloy steel with a high chromium content (about 13%).

The advantages of metal stoves over stone and brick ones are that the use of a potbelly stove in a bath allows you to completely remove the smoke without the danger of smoke in the room, besides, metal stoves are compact, easy to install and heat up several times faster than stone stoves.

The disadvantages of a potbelly stove include: the need for constant refilling of fuel, as well as its high consumption.

Content

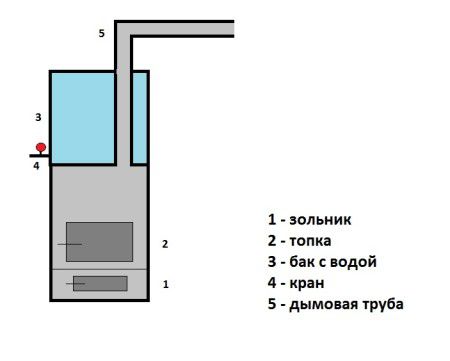

The main parts of the construction of a potbelly stove for a bath:

- foundation;

- firebox and blower;

- grate and a box for collecting combustion products (ash, ash);

- heater with a window for steam output;

- chimney (to improve heat transfer, the pipe is often made in the form of a spiral or zigzag);

- a tank of water (per person take a volume of water 10 liters);

- brick cladding.

The water tank is welded from steel sheets of increased thickness. A woodcutter can be provided next to the stove.

The principle of operation of the furnace

Solid fuel, burning in the furnace, releases heat, which is partly used to heat the room, and partly enters the chimney, which in turn heats the water tank.

Potbelly stove from a barrel or thick-walled pipe with a water tank

This is the simplest and most popular design of the sauna stove.

For its installation you will need:

- skills of owning a welding machine and a grinder;

- cutting wheels;

- electrodes;

- barrel (or thick-walled pipe) for the firebox and water tank;

- tap;

- smoke exhaust pipe;

- bricks and cement mortar;

- metal corners and bars for the grate;

- loops (or segments of suitable bars and hollow metal tubes);

- sheets of heat-insulating material;

- heat resistant paint.

The easiest way to make a potbelly stove with a round cross section is from a piece of thick-walled pipe, an ordinary metal barrel, or from curved and hermetically welded sheets of metal.

Step-by-step instructions for creating a potbelly stove for a bath

If you decide to take a fundamental approach to this issue and do everything “for centuries” so as not to do repairs every few months, we recommend that you strictly follow our instructions! It has been tested more than once, thousands of people have built their furnaces using this technology, it has been time-tested!

Foundation

The most reliable foundation is a layer of cement below the floor level, two layers of waterproofing material (roofing material) and two levels of brickwork. A reliable foundation will eliminate the warp of the furnace and ensure the proper level of fire safety.

- We dismantle the floor and dig a pit. The size of the pit is calculated based on the size of the furnace with a margin of 30 cm around the perimeter. The optimal depth is about half a meter.

- We put a layer of broken bricks or small gravel at the bottom of the pit, tamp it down and fill it with cement mortar, checking the horizontality of the pour.

- After the cement dries, two layers of roofing material are laid on it.

- Two levels of burnt bricks are laid on top of the roofing material. The first level of the brick is placed on the edge. Refractory brick resists moisture well and withstands high temperatures.

Firebox assembly

- The metal can or pipe used to make the firebox should be about three millimeters thick.We cut the pipe with a grinder on both sides so that we get a cylinder of the required volume.

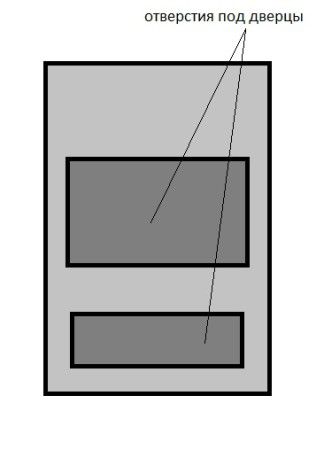

- We cut out the doors - for laying fuel and for blowing. In the absence of a grinder, work is carried out with a hammer, a chisel and a hacksaw for metal. Irregularities are cleaned with a file.

- Inside the furnace (between the blower and the furnace), we weld four stops to install the grate.

- The grate itself is made of metal wire or bars welded together. The grille does not need to be welded to the limiters.

- We cut out two circles from sheet metal, the size of which corresponds to the diameter of the pipe (barrel). In one of them we cut a hole for the chimney. Hermetically weld them to the oven.

- For the doors we use the remaining pieces of metal. We weld handles, hecks and hinges to them. The simplest loops are made from segments of a hollow tube and a metal bar of the appropriate size.

Chimney and water tank

The flue in a bath consists of internal and external parts. The inner part is in the room and passes through the tank with water, heating it.

The outer part is equipped with a fungus to protect against precipitation and dirt. In places of contact with combustible surfaces, it is isolated with asbestos sheets.

We weld the first, inner part of the chimney to the furnace. Next, we install a water tank on top of the furnace. We weld it hermetically to the firebox. In this case, the chimney must pass through the tank. We cut a tap for water into one of the walls.

After that, we build up the pipe to the level of the floors and bring it out through the roof to the street.

To close the chimney after the end of the furnace, a valve is mounted.To do this, during the assembly process, the pipe is drilled, and a metal circle fixed on a bar is installed inside. Principle of operation: with the turn of the bar, the position of the metal damper inside the pipe also changes, changing the size of the gap and the amount of air and smoke circulating inside it.

Facing

The outer part of the furnace (except for its frontal part) is lined with refractory bricks. This improves heat transfer and contributes to a more uniform heating of the room. The metal parts of the oven may only be painted with heat-resistant paints (to protect the oven from corrosion).

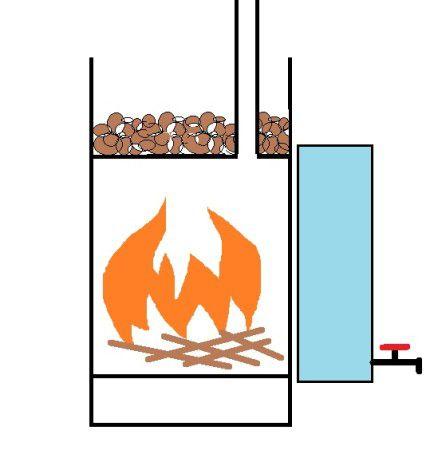

Potbelly stove with a remote tank

A potbelly stove with a remote tank is more practical. A tank of water is brought in and fixed next to one of the walls of the furnace. For the fastest heating of water, the tank and the firebox are connected with metal pipes in which heated water circulates. The main structural parts of the furnace are unchanged: the ash pan and the fuel chamber, the chimney, the grate. An open metal “glass” is mounted on top of the firebox by welding, in which stones are placed.

Stones should be chosen heat-resistant, not afraid of a sharp temperature drop. Otherwise, poor-quality material, when water drops hit a hot surface, may crack, release unfavorable impurities into the air, and retain heat poorly. The aesthetic appearance of the stones used in sauna stoves plays an important role in the choice.