Potbelly stove though and has more than a century of history, but even today it has not ceased to be a very popular heating device for small rooms.

Such a furnace is made not only from solid sheets of metal, but also from various metal objects that can withstand the heat from an intense flame. — it can be a barrel, a flask, a pipe or an old gas bottle.

It is especially popular among avid motorists who, even in winter, cannot refuse improvements in his car, spending everything in garages his free time. The gas cylinder has an ideal shape, it is practically a potbelly stove, it just needs to be slightly improved: cut off the excess, drill the necessary holes and weld a few pipes! Let's take a closer look at how to make a potbelly stove from a cylinder?

A potbelly stove from a gas cylinder can have a vertical or horizontal arrangement. Some craftsmen make such furnaces even from two cylinders, placing one of them vertically on top of the other, which is oriented horizontally.

Content

Video: homemade wood burning potbelly stove from two cylinders

However, there are many models, and, having considered different ones, you can choose the one that seems more convenient to use and acceptable in ease of execution.

Naturally, for the manufacture of a potbelly stove from a cylinder, some tools and materials, and certain skills to work with them.

What needs to be prepared?

From tools need to collect:

- welding machine (200BUT);

- grinder - "Bulgarian", better with discs with a diameter of at least 180 mm;

- electrodes;

- circles for grinding and cutting metal;

- a hammer that cleans the slag from welding;

- brush with metal bristles;

- metr ckokay, tape measure, chalk or marker for marking;

- drill and drill required diameters;

- chisel, normal hammer and pliers.

From materials, except for one or two gas cylinders, you must purchase:

- metal sheet, not less than three millimeters — it is useful for the device of the hob and ash pan;

- ready-made cast-iron doors, or they can also be made independently from a metal sheet or a piece of metal cut from a cylinder;

- flue pipe;

- corner or thick reinforcement - they will be required for the manufacture of legs and grate. The latter can be purchased ready-made (made of cast iron) or arranged using holes, drilled at the bottom of the bottle.

It should also be noted here that for the manufacture of such a stove fit as a standard gas bottle, so and balloon small size.

As mentioned above, a cylinder stove can be vertical and horizontal. You can choose the one you want based amount of space allotted for the installation of a potbelly stove and convenience her operation.

Balloon preparation

Proper balloon preparation — this is a very important event before starting work, especially if the potbelly stove is made of containers, which recently contained gas. Residues of gas may remain inside, and when cutting, which is accompanied by sparks, the cylinder may explode.

- Therefore, first you need to unscrew the valve located on top of the cylinder, and free the passage for the exit of residual gas — this procedure will take some time. It's better to leave capacity in open able for the night on open air or in a well-ventilated non-residential area, and more better — fill it with water to the very top.

- Next, the container is turned over and the resulting condensate is drained. It has a very unpleasant smell, so this process also cannot be carried out in a room where people live.

washed out capacity no longer harbors any explosive hazard when working with it, and you can safely proceed to the cutting process.

Vertical potbelly stove from a gas cylinder

- In the manufacture of this model, the cylinder is installed in its usual position, the neck is completely released, then marking is made using a tape measure and a marker.

- Further using grinders (or using a gas or plasma cutter), holes are cut for the device of the furnace and blower.

- next step goes grate device between the furnace chamber and the blower. Since this element of the desired shape and size is difficult to find, it is made from reinforcement. Her cut into pieces of the desired size and welded to a pre-marked place.

- Further doors are installed — cut pieces of metal are perfect for their manufacture. They are installed on hinges welded to the cylinder body.

- It is necessary to install latches or hecks on the doors — they should reliably hold the sashes during the firebox.

- At the top of the balloon if desired, you can arrange a small hob. It will always come in handy in order to make coffee or tea or fry scrambled eggs. This panel is made from sheet metal.

- The photo shows a variant of the preparatory basis not easy for the hob, and for installation from above containers for heating water, made like a samovar. The pipe leaving the furnace will pass through capacity with water, heating her.

- All seams with which any parts of the furnace are welded must be airtight.

- Chimney the pipe can be installed in the top of the oven or in the side wall. The chimney exits the room through the wall of the building or the roof.

This arrangement of the gas cylinder helps to save space, as the oven is compact and neat. She is especially good fit for a garage or a small room in the country.

Potbelly stove of horizontal type

- Another version of the cylinder stove, which the placed horizontally, too It has his advantage — on it you can arrange a large hob, which will be able not only to warm tea, but also to cook dinner.

- To the design of the potbelly stove stood steadily, for her cook from the corner reliable stand, and after completion of the work, the finished stove is fixed on it using spot welding.

- Work on the cylinder also begins with markings, after which a square hole is cut out for installing the door and a round — for the installation of a chimney pipe. With a round hole, maybe have to to be obtained if there is no cutter. "Bulgarian" is not an assistant here, so at first — drilling holes around the circumference, then working with a chisel and hammer, and then finishing with a file.

- Holes are drilled in the bottom of the future furnace, which will play the role of a grate, and under it a box is welded from a sheet of metal, in which the ash will fall.

- The same chamber will be a blower, so on her install an adjustable door so that you can reduce or increase the air flow to establish the desired traction.

- The door for this furnace can be made independently by scalding the part cut out of the cylinder, or you can install a finished cast-iron part that already has a frame. The second option will be easier to install, and it is already equipped with a latch for reliable furnace closure.

- After installing the door, the potbelly stove is fixed on a stand or legs of the desired height are welded to it.

- Then a pipe is welded onto which a chimney pipe will be installed. It can also be removed through a wall or roof.

Will a small balloon fit?

You can also work with a small balloon. Her are made according to the same plan as the horizontal type stove.

- But in this case, instead of drilled holes in the bottom of the potbelly stove, install a cast-iron grate. a window of the required size was cut out for it.

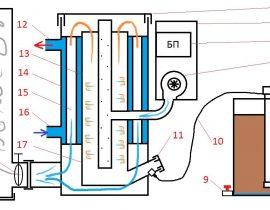

- The blower in combination with the grate is welded as follows.

- Further legs are welded onto the ash pan box, the structure is turned over and installed on top, and a branch pipe is fastened by welding for chimney

- After completion of work on the potbelly stove her installed in a permanent place and bring the chimney to the street.

Video: How to make a super wood-burning stove from a used cylinder

The proposed options are only a small part of what was invented by folk craftsmen. See how the craftsman combined brickwork and a gas cylinder in one potbelly stove:

If you have an idea about working with the tools described above and all the necessary materials, you can try to make this convenient, and sometimes irreplaceable oven yourself. Having done her with your own hands, you can save a fairly large amount, as well as make an already unnecessary gas cylinder function. The most important — approach this work responsibly and do her slowly, checking each action.