With a little effort and ingenuity, you you can build a compact potbelly stove for a summer cottage with your own hands, and we will help you understand the details of construction and take into account all the necessary details.

If you strictly follow our instructions, you can get a pretty nice stove, such as in the photo below:

it invention from metal has been known for a very long time, but even today it has not lost its relevance. Summer cottages, beloved by many, are not always supplied with gas, and electricity today costs not cheap. Spending spring and autumn days outside the city, when the nights are cold, willy-nilly, you think about making a heating device that can warm the cottage room and boil the kettle. So such an invention of mankind as a potbelly stove comes to the rescue.

This is all the more true if there is a forest or a large tree plantation near your site where you can find dry branches - you will always be provided with environmentally friendly fuel.

Her the design can be very different - from very simple or more complex. To know what potbelly stoves are, and what they can be made of, you need to consider several options.

Content

Types of bourgeoisie that can be installed in the country

Such a stove can be made from any metal containers or thick metal. Naturally, you will need toolsto help deal with this difficultbut creative work.Good for making potbelly stoves fit an old gas cylinder or two cylinders, depending on the stove model, two hundred liter barrel, pipes with a diameter of 50 cm or just sheets of metal with a thickness of 3—5 mm and corner.

- This model of potbelly stove is made of a metal barrel, to which the legs are welded.

- Then cut out in the form of a rectangle part of the bottom and seatedon the on the loops — so it turned out the firebox door.

- In the end inverted on the side containers a round hole is arranged to which a chimney is welded.

- At the bottom of the oven, it is necessary to lay grate-grateso that it does not burn out, and the oven retains heat for as long as possible.

- A thick steel wire is welded on top of the barrel so that you can put a pot or kettle — thus, a hob is obtained. This is the easiest and most affordable way to make a potbelly stove.

More one model that can be made from both a pipe and a barrel. It is somewhat more complicated than the previous one, but the efficiency of this stove will be much higher.

- On the containers cuts are made and sections are removed from which doors for the firebox and blower will be made. Hinges are welded and doors with shutters are hung on them.

- Inside containers stands for the grate are arranged.

- If the oven is made from a pipe with a large diameter, her the bottom is brewed, and legs are attached to it. Also brewed her top - it turns out a kind of hob, in which a round hole is made for the chimney.

- If the stove is arranged from a barrel, it already has a bottom and a hob. Legs and a chimney are also welded to it.

A pipe for making a potbelly stove is preferable than a barrel, since her service life will be longer. The efficiency of a stove made from a pipe with thicker steel walls is much higher than that of a potbelly stove from a barrel.

This oven is great fit for a summer residence, but same way, like any potbelly stove, requires her operation, compliance with safety regulations and isolation from combustible objects, wooden floors and walls.

This version of the potbelly stove is made from a gas cylinder. It does not have a hob, which reduces the functions of the stove to one — space heating.

- Holes are drilled in the bottom of the future stove to dump ash into the welded under improvised lattice ash pan, which is made from a metal sheet. The ash pan plays a role and blew — to close it, a small door is arranged. Further legs are fixed to the bottom of the potbelly stove by welding.

- From the bottom of the balloon become now the front wall of the furnace, also part cut out which will serve as a door, then it is installed on welded hinges. A pipe is welded on the opposite side of the furnace. She may be installed on top of the bottle or behind the oven.

This is also a fairly simple design of a potbelly stove, which can be done independently.

Another version of the stove-potbelly stove from a gas cylinder is done as follows:

- Cut off its top part, where will be be a door, and a side part for hob settings.

- Further legs are welded to the future stove, and a door is installed.

- A round hole is cut into the hob for chimney pipes.

- Best in bottom parts of the oven to make holes and provide an ash pan.

- For safe operation, the potbelly stove must be installed on non-combustible material, and if the walls of the building are wooden, then one cannot do without their insulation either.

This model is quite simple in execution and well fit for use in the garden or in the garage. The hob is large enough to her you could put a kettle and a pot or pan at the same time.

It is possible to complicate the task somewhat, while raising the efficiency of your product. So, potbelly stove for giving with their own hands, they are also made from two cylinders, as, for example, shown in the attached video:

Video - The process of creating a do-it-yourself potbelly stove

A more complex version of a potbelly stove made of a piece of metal pipe, in the lower part, which is fixed in the form of a bottom lattice.

The upper part is a circle cut out of a sheet of metal, in German being done hole, then a chimney pipe is welded into it. This whole structure is embedded in a folded four or five rows of brick box, which will act as a blower. Its height is calculated according to the width of the blower door. The furnace is installed permanently, the chimney can be brought out through the wall or roof.

There is also such an option as a potbelly stove that runs on waste oil, which is poured into the lower tank and set on fire. This oven has a few drawbacks. — uhthen then, what it can warm a very small room, and then, what her operation may result in odors from fuel combustion. It should be noted right away that this option is more fit for a garage or utility room, rather than for a living space, but you need to take note of it, since a garage may also be present at the summer cottage.

- From iron sheet cut out necessary elements – (the shape can be round or rectangular), and the fuel tank is made from them.

- Two holes are cut in the upper part of the tank for a pipe and for refueling. The second should have a sliding cover.

- Legs are welded to the resulting tank.

- A pipe with small round slots is welded into a large hole, through which inside air.

- Then the top tank is made — secondary combustion chamber, which is welded to a slotted pipe.

- The top tank must have a lid. removable, and in it should be hole for the chimney, which is displayed on the street.

After complete assembly, you can start testing this project of yours.

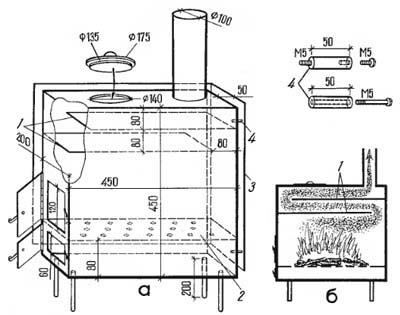

This stove model — good choice to use her in the country. The neat shape makes her acceptable for any country interior. It will help not only to warm the room, but also to cook food, as it has a fairly large hob. Everything is very well thought out in the design, including the size of the external surfaces and the firebox, in which there is enough space for filling her firewood. These qualities of speech will quickly heat up a cold room.

- For manufacturing, you will need sheets of thick metal in 3—5 mm, corner and pipe for the chimney.

- First, all parts of the structure are prepared according to a pre-prepared scheme.

- The planes are connected with metal corners by welding — they will also serve as legs for the stove. From the lower end of the legs it is necessary to strengthen the metal plates, about 10x10 cm for greater stability.

- The firebox should be separated from the blower-ashpit grate-grate. Further the doors of the firebox and blower are fixed on the hinges.

- Then, in the back of the hob, make a round hole for the chimney, fix it and withdraw outside.

The most successful and effective version of the potbelly stove, which has high efficiency, and it will be great to warm the cottage room for long years. In form and materials, it would seem that it does not differ much from the previous model, but the internal her the design is somewhat different. This helps the stove to cool down much longer and give off more heat into the room, rather than releasing it into the chimney. Two metal plates help to achieve such performance, which are fixed in the upper part of the furnace near the chimney. They create obstacles to the rapid exit of hot air directly into the pipe. One of the plates is welded to the front internal parts of a potbelly stove, the second to internal back wall. Thus created "maze" waiting combustion products makes them go around these plates, and in the created upper chambers, afterburning gases. This type of potbelly stove can remain hot up to 11—12 hours. Moreover, the hob has removable burner cover, which will allow you to quickly heat the water in the kettle.

The efficiency of such a potbelly stove reaches 70% , the average heat transfer is 1360 kcal/h The hob heats up to 150—160 degree sidebar — up to 100—110 degrees.

There is no need to doubt that a potbelly stove is useful in a summer cottage — near her it's nice to sit in rainy weather or on a cold evening, listening to the kettle boiling on the stove. If there is an opportunity and skill, necessarily do her on one's own — Thus, you will save quite a large amount of money.