Most owners of country houses and cottages prefer to independently equip the heating system by building fireplaces and stoves. This, of course, requires a certain experience, knowledge and understanding of the construction technology.

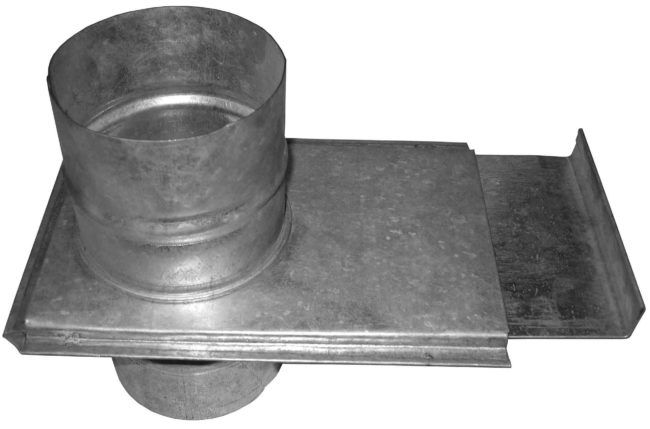

Gate damper - photo

One of the necessary elements for the furnace, ensuring its efficient operation, is a chimney slide valve. In this article, we will try to explain to you the principle of its operation and the step-by-step process of creating and installing it yourself.

Today, a stylish fireplace or an exclusive stove is no longer a luxury item and, if desired, you can build it yourself. In this article, we will describe in detail what a chimney gate valve is, its main purpose and installation features.

Content

Purpose and characteristics

This device allows you to control and regulate the draft to the smoke exhaust system. Translated from German,

gate ("schieber")

Shiber ("schieber") means a part that is made of a certain metal.

Good traction is one of the key conditions for the normal operation of the fuel system. With good traction, the fuel burns almost completely, providing an efficient and economical heating process. If the draft is bad, then smoke in the room and a fire may occur.

To eliminate these dangerous and unpleasant moments, a slide damper is installed in the chimney system. It prevents the division of gas bubbles, which should not be separated.

The sliding damper is recommended to be installed when heating with gas, coal, solid fuel.

Main functions of the gate valve

Being the main draft regulator inside the chimney, the damper regulates the combustion of fuel. To reduce the draft and reduce the intensity of the flame in the furnace, it is enough to cover the gate valve. To increase traction, on the contrary, it is necessary to open it.

In fact, the gate is an ordinary metal plate that allows you to adjust the thrust.

It can be installed both in single-wall boiler systems and in double-wall boiler systems.

If the fireplace with the stove is not in use, then during this period the gate valve must be in the closed position.

As a rule, the valve is installed on the initial section of the chimney (on the first meter), since this particular area remains uninsulated.

But on the site of a well-insulated chimney, on the contrary, it is not recommended to install a valve. Especially when it comes to double-circuit pipes. When the metal of the inner and outer pipes expands, the slide gate may jam.

So, the main tasks of the gate valve are:

- The function of the draft regulator in the chimney.

- Partial overlapping of the section of the chimney channel.

- Flame intensity regulator in the furnace.

Attention! If combustion in the furnace is carried out when fresh air is supplied, the slide valve to the chimney not installed!

Visual demonstration of the efficiency of the slide valve (video)

Closed gate:

Open gate:

In most cases, the gate is made of stainless steel with a thickness of not more than 1 mm. Such a part is able to withstand temperatures up to 9000C, characterized by corrosion resistance and low coefficient of thermal expansion.

In order to maximize the ease of operation of the chimney and good cleaning of soot, the damper surface must be polished.

The joining of the seams is performed by rolling.

A standard damper covers up to 85% of the chimney, which is the optimal indicator for the effective removal of combustion products.

The main types of gate valves

- Horizontal sliding gate.

Horizontal slide gate

The plate located inside the damper is extended, due to which the cross-sectional area of the chimney is adjusted. Typically, this version of the valve is used for installation in brick chimneys. Often, small holes are made on the surface of the plate so that even in the closed position of the gate, it does not block the smoke channel by 100%. This is in line with fire safety regulations. The advantage of this type of device is the ease of installation.

- Swivel gate. It is also called "throttle valve",

Chimney damper

which is a metal plate fixed on a rotating axis. The axis, in turn, is mounted inside the chimney pipe.This device has a removable rotary disk, but with prolonged use it may become unusable. However, the scheme of the rotary mechanism allows you to repair and replace it with your own hands. The advantage of this type of device is ease of use. This type of gate does not require constant monitoring by the owner of the house.

Due to the complexity of the do-it-yourself design, the rotary mechanism is less often used when laying a fireplace or stove.

The gate design is necessary for wood-burning stoves and heating devices operating on any solid fuel.

As for gas boilers and liquid fuel boilers, here the damper rather plays the role of protecting the chimney from atmospheric precipitation.

Therefore, for a gas boiler, the most practical solution would be to install a rotary mechanism. The temperature of the exhaust gases is less low than during the operation of solid fuel, so the operation of such a mechanism will be most convenient.

Valve on the insulated chimney

But it is better to refuse to install a rotary mechanism in the bath. The fact is that it will partially pass steam when closed. And in the open form, such a mechanism is difficult to clean.

Made of stainless steel, the slide mechanism will not completely cover the chimney, but at the same time it will exclude the possibility of flames escaping through the ash pan into the room.

There are three options for installing the gate.

- Installing a damper in a fireplace insert. To do this, the gate is mounted at a distance of 1 meter from the heating device, which ensures simple operation.

- The “pipe to pipe” option involves combining the gate with other elements of the heating structure without additional use of fasteners.

- Installation of a gate valve in a ventilation pipe. But this option is usually used to protect the fan motor from overheating during its operation.

When purchasing ready-made chimneys, the kit will most likely be equipped with a gate valve, which simply needs to be installed according to the instructions.

But even if the finished kit comes without this element, the gate can be easily made with your own hands, choosing the most optimal version of the mechanism for yourself.

DIY manufacturing

Option 1. Making a stainless steel rotary valve

We offer detailed instructions for the manufacture of the damper already with the finished stove heating, when the design is completed, but the gate mechanism was not provided.

To make and install a gate with your own hands, you will need the following materials:

- grinder, cutting and grinding abrasive wheel;

- drill;

- tap;

- oil for lubricating the tap when threading;

- a hammer;

- vise;

- pliers;

- welding;

- core;

- electrodes for stainless steel;

- compass;

- roulette;

- permanent marker.

From the materials you should immediately prepare:

- stainless steel sheet 1.5 -2 mm thick.

- stainless steel tube with an inner diameter of 6 mm;

- 2 bolts 8mm,

- nail (or metal rod).

When all the tools and materials are prepared, you can begin to work.

- Measure the inside diameter of the pipe and mark it on the stainless steel sheet with a compass.

step 1

- Now, using the grinder, cut out the circle according to the markup.

Step 2

- We try on the cut-out damper, if necessary, refine it with a grinding wheel until it clearly enters the pipe.

Trying on the damper

- Take the prepared stainless steel tube and attach it to the finished circle.Measure with a marker to the size of the damper. We make it smaller than the inner diameter by 3 mm on each side.

Step 4

- We cut the pipe with a grinder with a cutting wheel.

- We drill an inner hole in the 6.8 mm tube for threading. When drilling, it is necessary to periodically lubricate the inner surface of the tube with machine oil.

Drilling the tube

- We cut an 8mm thread on both sides of the tube with a tap, not forgetting to lubricate the tap in the process. To remove the cut chips, it is necessary to make a half-turn return every half turn of the tap on the thread.

Step 5

- Now you need to make three holes in the damper. Mark immediately with a marker.

- Clamp the tube and the damper in the clamp and weld the tube to the damper through these holes (weld rivets). We start welding from the central hole, then we release any one clamp and weld it into the vacated hole.

Step 6

- We make markings for future holes on the smoker. In order to clearly match the axis of the holes, wrap the pipe with a tape measure and measure the center horizontally and vertically. Drilling.

Making markup

- We assemble the damper into the tube.

Step 7

- We make a template for the damper retainer.

Step 8

- We transfer the markup to a metal sheet. You can use a compass.

Step 9

- We mark the middle for the holes of the latch, cut and drill according to the markup.

- Weld to the pipe.

We weld the latch

Option 2. Making a horizontal retractable stainless steel gate

For this option, it is necessary to purchase a ready-made factory stainless steel gate valve. The design represents a frame inside which the mechanism moves.

- Lay out 2 rows of stove or fireplace according to the ordering scheme used.

horizontal slide gate

- On the row where the valve will be installed, we cut grooves in the brick. These are small grooves into which the metal element will enter. It is best to use an angle grinder with a wheel for these jobs. But if there is no such professional tool, then you can get by with a file.

- The damper is installed.

- In the side brick, it is necessary to cut a recess for the damper handle, because it will need to be cleaned of soot during operation.

We block the gate next to the bricks

- The next row of bricks is laid and all gaps formed are well sealed.

As you can see, the manufacture of the gate does not require a lot of time and a lot of experience. At the same time, this is a very important detail that will significantly increase the efficiency of the boiler or fireplace.

If you have additional questions - you can ask them in the comments, we will try to answer as soon as possible, thank you for your attention!

"Attention! If combustion in the furnace is carried out with the supply of fresh air, the slide valve on the chimney is not installed! I don't quite understand this comment. After all, any combustion is accompanied by the supply of air to the furnace ...