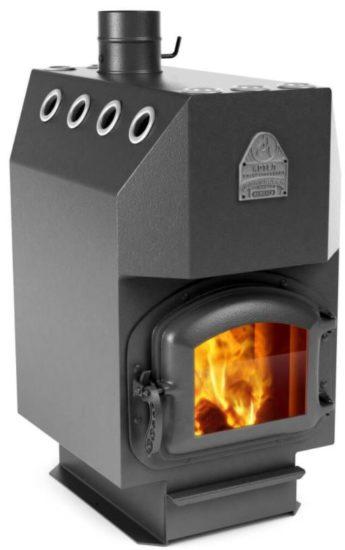

The stove is the most efficient and less expensive way of heating the internal space of the greenhouse compared to the installation of a heating system. Improperly organized heating can cause a lot of trouble and negatively affect the size of the crop. Therefore, it is important to choose a stove that matches the parameters of the room and has maximum efficiency.

Content

The subtleties of furnace heating in the greenhouse

Most gardeners use a stove to heat their greenhouse in spring and late fall. Winter heating is often not cost-effective. The presence of a vestibule, ventilation and gas outlet in the greenhouse helps to increase the efficiency of the furnace and at the same time reduce fuel costs.

The working principle of any model is as follows:

- Cold air from the street enters the room through a pipe in the upper part, equipped with a damper.

- Fuel is placed in the lower compartment. But the access of oxygen to it is limited, so combustion is slow. The fuel does not burn, but smolders. The intensity of the process is ensured by competent adjustment of the damper.

Thus, the minimum amount of fuel ensures a long-term, gradual heat transfer.

When installing the oven, it is important to consider the following points:

- The primary task in a greenhouse is to warm the soil, not the air. Therefore, the furnace must be located closer to the ground.

- Another option is to raise the beds by 30 - 40 cm or install boxes with seedlings on the shelves.

Connecting a water circuit to the furnace will additionally provide heating of water for watering plants.

Types of ovens

With a set of materials and a little experience, you can build a stove with your own hands. But if you don’t want to burden yourself with unnecessary work, you should purchase a ready-made model. To make the right choice, you first need to study the characteristics of different models, their pros and cons.

Vologda

Model with high heat transfer rates. Requires bookmarking fuel only 2 times a day. Furnace efficiency - up to 80%. The principle of operation resembles the combustion of a gas generator. The heat carrier is supplied through flexible hoses attached to the rear wall of the boiler and the fuel tank.

The model is rarely used in private greenhouses, although its installation is advisable for large areas. The shape of "Vologda" is a large barrel, located horizontally.

The model is rarely used in private greenhouses, although its installation is advisable for large areas. The shape of "Vologda" is a large barrel, located horizontally.

Exhaust pipes are welded to it. There are several oven options. The smallest one passes through the tubes 5 cubic meters of air per minute.

Disadvantages of the model:

- there is no possibility to adjust the temperature;

- bulky and inconvenient to install;

- requires systematic monitoring during combustion.

- high price.

Butakov oven

This model got its name from the name of the designer. Currently, several domestic factories are engaged in its production.

This model got its name from the name of the designer. Currently, several domestic factories are engaged in its production.

The line of manufactured models consists of several types designed for heating rooms of different sizes:

- Gymnasium student;

- Student;

- Engineer;

- Docent;

- Professor.

For small greenhouses, the smallest option is recommended - "Gymnasist".

Structurally, the Butakov furnace is a fuel tank with 3 mm thick steel walls and 2 types of pipes heated along the entire length:

- The lateral ones are curved and crossed among themselves in the upper part.

- Front and rear - convection, supplemented with special afterburner jets for supplying secondary air to the chamber.

The design improves the heat exchange process in the furnace, which contributes to an increase in efficiency. The furnace can be used in normal mode and in gas generation mode. In order for the Butakov furnace to start working in the long-term burning mode, it is necessary to completely close the ash pan and close the gate by 2/3. Then it will not burn the wood itself, but the gas emitted by it.

The oven will be able to work up to 12 hours. To do this, before starting the kindling of the furnace, the combustion chamber is filled with fuel to the maximum, the gate is set to the desired position and the height of the chimney must comply with the necessary standards for a given volume of the furnace.

Only wood or sawdust can be used in Professor Butakov's stove. Coal cannot be used in such a model, since its combustion temperature is not acceptable for the metal from which the body is made.

When buying a Butakov furnace, it is important to carefully consider the proposed model. Not all manufacturers build secondary combustion chambers into them, which reduces efficiency and requires frequent firewood during use.

Buleryan (Breneran)

A German or American-made furnace Buleryan and its counterpart Russian Breneran is a gas generator from two combustion chambers:

A German or American-made furnace Buleryan and its counterpart Russian Breneran is a gas generator from two combustion chambers:

- lower - gasification;

- top - burning.

On the front side of the furnace there is a door for loading fuel and a gate for adjusting the power.On the back side of the firebox there is a combustion pipe. A chimney is attached to it.

Pipes for cold air intake and hot air exhaust are mounted on the top and bottom of the furnace. The furnace works economically due to the pyrolysis process. The air in the greenhouse is heated not due to heat transfer from the fuel, but with the help of the gas released by it during combustion.

Potbelly stove

The simplest design for heating greenhouses. Her device is elementary. The barrel-shaped firebox is equipped with a door, a chimney, a pipe for the exit of warm air and a jumper in the upper third of the tank for fuel loading.

The simplest design for heating greenhouses. Her device is elementary. The barrel-shaped firebox is equipped with a door, a chimney, a pipe for the exit of warm air and a jumper in the upper third of the tank for fuel loading.

The heating of the room is due to the following:

- Moving hot smoke through a pipe laid in the central part of the greenhouse or along its sides.

- Radiation of heat from oven surfaces.

- Hot air formed above the bulkhead and exiting a special pipe.

A potbelly stove can work on waste lumber, firewood, coal. The intensity of combustion depends on the nature of the fuel and the access of air to the furnace.

It is worth choosing this method of heating only when there is the possibility of constant control over combustion. The need for systematic fuel loading is a significant minus of the Potbelly stove.

Bubafonya - improved Potbelly stove

The model was named after the creator - Athanasius Bubyakin. The design refers to long-burning furnaces. The design consists of a fuel tank, divided into parts by a pressure circle - a piston. It relies on the fuel embedded inside. As a result, fuel is burned in the lower part, and pyrolysis gases are burned in the upper part. Oxygen is supplied inside through a pipe, which simultaneously performs the function of a piston handle.

Any fuel can be used in the stove, including household and garden waste. The advantages of the model are simplicity of design, efficiency and the ability to operate without supervision. However, there is Bubafoni a significant drawback is the small radius of action. To solve the problem, the design must be supplemented with a fan.

Slobozhanka

Outwardly, this stove resembles a Potbelly stove, but supplemented by a gas generator and a heater. The efficiency of the furnace is increased by the use of combustible gases. They are not brought out, but serve as an additional source of heat.

Fuel is loaded into the combustion chamber from above. The entire process of heat release occurs in a downward direction.

Fuel is loaded into the combustion chamber from above. The entire process of heat release occurs in a downward direction.

Based on the specific design of the Slobozhanka, there are three ways to supply air - through:

- Pipe opening from top to bottom with L-shaped feed.

- A pipe located in the center of the device. The air in this design comes from below.

- Side pipe located at the very bottom of the furnace.

The body of the Slobozhanka is barrel-shaped, inside which there are seven vertical pipes. The model includes:

- lack of a pallet to remove unburned residues;

- the need for regular fueling.

How to choose fuel

Long-burning furnaces operate on almost all types of fuel: coal, wood, sawdust, mining.

The choice depends on the parameters of the greenhouse:

- Sawdust - an affordable type of fuel for summer residents, next to the site of which there is a sawmill. Most often, they can be taken for free, since workers simply collect and discard this waste.

- Firewood - the best choice for a greenhouse stove. In a small greenhouse, fuel can be laid once a day. Firewood is affordable and environmentally friendly.

- Coal. The main advantage of this type of fuel is its high calorie content. Disadvantages - the release of toxic substances, as well as a large amount of waste. Some types of coal can be dangerous if stored improperly, as they are prone to spontaneous combustion.

- Briquettes. This type of fuel combines the advantages of wood and coal. Briquettes are characterized by rapid heating, support long-term burning. Fuels have high efficiency, efficiency and absence of harmful emissions.

Kiln Selection Criteria

The most affordable option for heating a greenhouse is a potbelly stove. This design is low cost and easy to use. However, the Potbelly stove is not without its shortcomings. It must not be left unattended, since it is necessary to constantly add fuel to maintain combustion. In addition, the air from such a furnace warms up unevenly.

In order to minimize labor costs and at the same time obtain high-quality, systematic heating of the greenhouse, it is better to opt for one of the models of long-burning stoves. The cost of such units is an order of magnitude higher, however, the efficiency also exceeds the Potbelly stove at times.

When choosing a model, it is important to consider:

- greenhouse area;

- available type of fuel.

If the greenhouse is small and heating is provided only in case of a sudden cold snap, it is not advisable to buy a serious long-burning stove. In this case, it is quite possible to manage the budget potbelly stove.

For medium-sized greenhouses intended for early planting, the best option is Vologda or Bubafonya. They are able to maintain the desired temperature without additional fuel supply for 10-12 hours in a row, but at the same time they have an acceptable cost.

For large greenhouses, it is preferable to purchase Buleryan ovens, Slobozhanka or Butakov oven. These models are usually expensive, but they are characterized by increased efficiency. Plus, manufacturers offer a wide range of oven sizes designed for rooms of various sizes, which is economically beneficial for owners of industrial greenhouses.

Questions about the operation of furnaces

The maximum reduction in air supply helps to increase the rate of fuel burnout. You also need to stack the firewood very close to each other, and do not stir up the coal so that it slowly smolders and does not burn with a bright flame. A tricky method of keeping warm is a bucket of sand mounted on a stove.

The pipes of this furnace located in front of the firebox are supplemented with special injectors for afterburning the resulting gases. If they do not burn out, then the chimney is not working correctly. It is too low or clogged. Do not reduce the diameter of the chimney. There is one for every oven size. For the smallest Buleryan, the diameter should not be less than 120 mm, and for the largest - at least 180 mm.

Choosing the right stove for a greenhouse is a guarantee of rich harvests with minimal fuel costs.

Video review of a long-burning stove for a greenhouse