A fireplace is a stone or brick structure in the wall, resembling a niche, has a chimney to remove combustion products into the atmosphere.

corner fireplace

It is used as an interior element or for the purpose of heating a room (together with the main sources of heat).

It is advisable to design and build a fireplace between two internal walls. During the construction of the fireplace in the walls near the window, draft (active air circulation) is formed, which contributes to the occurrence of drafts in the room.

Content

Design and drawing of a corner fireplace

To calculate the optimal dimensions of the fireplace, you should determine the volume of the room, then create the following drawings:

- construction in section;

- drawing of each individual row;

- fireplace facade design sketches.

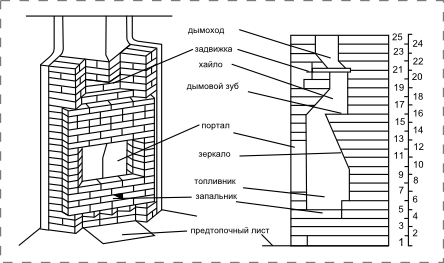

If a room volume no more than 15 square meters, then the area of the fuel hole will be 0.3 square meters. Firebox dimensions (niche, which is laid out of refractory bricks) are determined by the proportions of 2: 3 (height to width). That is, with a fuel hole area of 0.3 sq.m. the dimensions of the firebox are 56x40 cm. The optimal value firebox depth - 0.5-0.3 to the height, that is, at a height of 56 cm, the depth of the firebox is 25-29 cm. Smoke hole size calculated according to the proportion 1/10 - 1/15 of the area of the firebox. For a square pipe, this will be - 14x14 cm, for a round pipe - 10-13 cm (diameter). The height of the pipe is about four meters (the pipe should protrude 30-50 cm above the highest point of the roof).

The side walls of the firebox are deliberately laid out with a slope (the slope increases heat transfer by increasing the draft in the fireplace).

A special protrusion is built above the level of the firebox, which prevents soot from falling down from the pipe, and also excludes the ingress of smoke and cold air into the room (smoke tooth).

With the proper construction of drawings, it becomes possible to individually calculate the number of bricks.

Additionally, the lining (steel or bronze plates) of the fireplace walls increases heat transfer.

Construction materials

For construction it is necessary to prepare:

- refractory brick (quantity according to the drawings, grade not lower than M200);

- sand (fine fraction);

- refractory clay;

- crushed stone (2-6 mm);

- Portland cement;

- fittings and steel corners;

- smoke damper;

- spark arrester (nozzle for fire protection in the form of a cone) and deflector (for wind protection and increased traction) for the pipe;

- grate grate;

- screen;

- waterproofing material (for example, roofing material);

- level, hammers, trowel;

- cladding materials.

Foundation for a fireplace

The base of the fireplace is built independent of the foundation of the dwelling, taking into account the ceiling beams and rafters (the fireplace pipe should not be close to them). The width of the foundation is made ten centimeters more than the width of the first (basement) row.

- We dig a pit with allowances of 10-15 cm (from the width of the foundation) with a depth of about 60 cm.

- We lay down and tamp the crushed stone (layer 10-15 cm).

- We manufacture and install a formwork treated with bitumen or lined with a layer of waterproofing material at the bottom of the pit.

- Fill and level the layer of rubble (proportions: cement 1 part, sand 3 parts, crushed stone 5 parts). The level of the buta must be lower by the thickness of one brick than the level of the floor.

- We cover the foundation with polyethylene, leave for one week.

If necessary, the foundation is reinforced with reinforcement.

Masonry corner fireplace

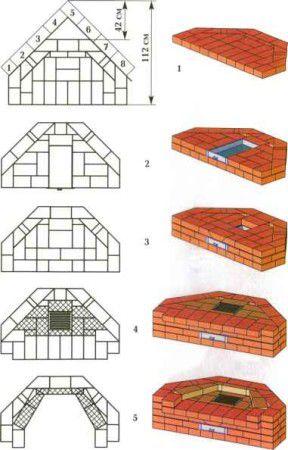

The base of the fireplace (the part located under the firebox)

- On a dry foundation, we lay the waterproofing material in two layers.

- We soak the brick (without chips and cracks) in water for about three minutes, prepare the solution.

- We perform grinding of bricks (we lay them without mortar, then we adjust the size according to the drawing).

- We lay out the first (basement) row of bricks with a continuous sheet, placing the bricks on the edge, in the next row we lay the brick flat, while making a niche where a metal box is inserted to collect the ash. In the third row we lay out a layer of bricks, overlapping part of the ash box. The fourth row is laying out the fireplace insert tray and installing the grate.

We form the overlap by laying out the fifth row with a slight extension of the bricks forward.

Video - laying a fireplace

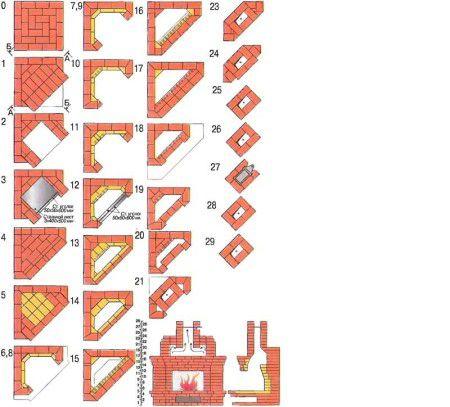

Firebox by the fireplace

We lay out the fuel chamber with a brick (6-9 row). As we lay, we check the verticality of the walls. Next lay out the corners for construction fireplace portal and we continue to build the outer walls and the firebox. In the 13th-14th row, you need to create the base of the mirror and complete it by the 19th row.To do this, either the bricks are laid with a protrusion of 5-6 centimeters, or the bricks are placed vertically with an inclination. In the 19th, 20th row we narrow the furnace, pushing the bricks forward a little.

Important! In order not to get confused, it is necessary to number each row of masonry with chalk.

In the 21st row, we begin to form a ledge with a slope of 20 degrees - the oven tooth (the construction of the tooth continues in the 22nd and 23rd rows). 24th and 25th row - we build a mantelpiece, brick laying is straight. Next, install the oven grate and lay out the chimney with a brick.

Important! When cutting bricks, use eye and respiratory protection against dust (construction goggles and gauze bandage).

In the underground space or behind the wall of the fireplace, a blower channel is built, which is necessary for air access and fuel combustion. There can be one or more channels.

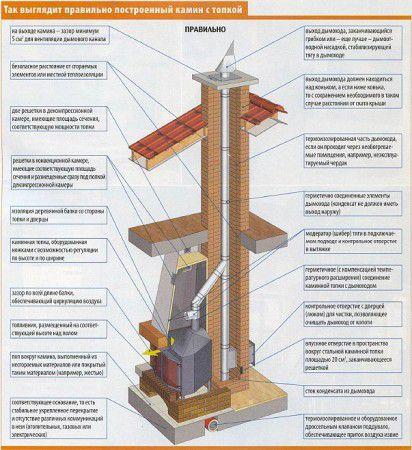

Chimney and chimney

The chimney is a part of the furnace, resembling a bell in shape, inside which a steel pipe (or ceramic chimney blocks) passes, which passes into the flue. The back wall is made vertical, and the side walls are made tapering at an angle of 45-60 degrees. The internal section is calculated according to the proportion: 0.1-0.15 of the portal area, and the height is made at least five meters from the fuel combustion surface. The walls are made thick enough to reduce heat loss.

At a height of about two meters, a valve is mounted. The frame for it is fixed with a liquid mortar in the masonry.

The first point of installation of the chimney is the installation of a block above the smoke collector. Cement mortar connects the holes of the pipe and the smoke box. Brick cladding is attached to the pipe by means of anchor joints inserted between the outer blocks of the pipe, which are embedded in the seams between the bricks. Internal surfaces must be free of gaps.

The head of the pipe is made with a thickness of at least 1 brick. To reduce the accumulation of condensate in the chimney channel and prevent the fire of structures, thermal insulation and thermal insulation are installed.

Components of the fireplace:

- Chimney for a fireplace.

- Support plate.

- Fireproof plate.

- Section of the pipe drive to the chimney.

- Firebox.

- To release hot air, a ventilation hole with a grill is mounted.

- Decorative element and thermal insulation layer.

- Ventilation grate.

- A chamber with hot air, a ventilation grill, outside the chamber is decorated with stone, marble and other material.

- Facing.

- Cold air movement.

A spark catcher and a deflector are installed on top of the pipe. The function of the spark arrestor is fire safety. Structurally, this detail is similar to a deaf metal cone with wire mesh on all sides. The deflector is installed on the head in order to increase traction and protect the pipe from the wind. Usually the deflector section is round.

Chimney and chimney lining

If it was planned to leave the outer part of the fireplace brick, without additional cladding, then the masonry should be as accurate as possible, and the mortar should not be brought to the front of the fireplace by 0.5 cm, so that it remains possible to expand the seams.

If the masonry requires additional decorative cladding, then artificial or natural natural stones, ceramic tiles, tiles and other materials are used. Top stones are recommended to be varnished to improve their decorative properties and facilitate care.

The cheapest and easiest way of cladding, which is done after the masonry shrinks, is plaster.Using various spatulas, a variety of decorative effects are created on the plaster. There is the possibility of coloring the plaster.

Another popular way of facing a corner fireplace is to use drywall. It is cut and attached to a special metal frame, strictly checking the corners and walls with a level.

Video - do-it-yourself drywall fireplace

For an aesthetic appearance, it is worth installing a beautiful screen in the fireplace. Most often, this element is made from metal mesh and forged elements.

According to fire safety rules, a sheet of steel is laid in front of the fireplace.

While reading the article, you understand that in general, making a fireplace with your own hands is not a problem, but when it comes to work, then the fun begins, everything does not go according to plan. Therefore, after suffering, I hired specialists, here they are, albeit for money, but laid out a fireplace with high quality.

Why problems? I read and posted, the savings are good, but I had nowhere to hurry, I put it for the soul.

If arranging a fireplace is a job for the soul, then there is nothing complicated, especially for a person with experience in construction. In other cases, it is better to hire specialists!